UK-based engineering tools provider Kingsbury and steel additive manufacturing firm Additure have been appointed by the UK Atomic Power Authority (UKAEA) to provide additive manufacturing know-how and experience as a part of the UK’s ongoing efforts to advance fusion vitality analysis. The partnership will help the event of elements designed to endure the acute situations inside fusion reactors, with a concentrate on modern supplies and design approaches.

A key space of focus entails using tungsten—layered with supplies comparable to copper—to realize the required sturdiness. To help this work, Kingsbury and Additure will ship and set up a Nikon SLM Options SLM 280 2.0 Laser Powder Mattress Fusion (LPBF) system at UKAEA’s amenities.

“We’re excited to help the workforce on the UKAEA as they scale, not simply with the SLM 280’s LPBF functionality, however with all the important thing parts of the AM ecosystem to make this a strong manufacturing resolution for UKAEA and the UK’s fusion programme,” stated Will Priest, Enterprise Growth Supervisor at Additure.

About UKAEA

The UK Atomic Power Authority (UKAEA) is the UK’s nationwide fusion vitality analysis organisation. It operates as an government non-departmental public physique, sponsored by the Division for Power Safety and Web Zero. A key a part of its mission entails fostering industrial fusion functionality by working with producers and provide chains to introduce and scale the applied sciences required for business fusion vitality deployment.

“The UKAEA goals to develop the commercialisation of additive manufacturing and help UK business within the transition into the fusion vitality sector. We conduct the complicated areas of analysis and improvement to the purpose the place it turns into commercially viable, the recommendation and help of our provide chain is vastly useful in expediting this course of,” stated Roy Marshall, Head of Operations for Fabrication, Set up, and Upkeep at UKAEA.

Additure’s Position and Know-how Contribution

On the heart of this initiative is the SLM 280 2.0, an LPBF system designed for high-performance functions, together with the event of refractory metals. The system provides construct speeds as much as 80% sooner than single-laser options and contains built-in security options comparable to a powder sieve module and system cooling enhancements.

Past tools supply, Additure can also be offering complete technical coaching to UKAEA’s analysis, supplies, and design groups. This contains detailed steerage on machine setup, construct optimization, and specialised capabilities—comparable to a heated lowered construct quantity.

“The functions coaching from Additure will present our engineers with new methods to design a few of the complicated constructions required by fusion and permit them to do that utilizing a few of the most difficult supplies to work with. For additive manufacture to contribute to fusion vitality, extra designers have to suppose, ‘What course of is most fitted for the specified thermal or structural efficiency?’ And ‘how do I create a design that’s finest optimised for additive manufacture?’”, stated Mr. Marshall.

Advancing Laser Beam Shaping 3D Printing

Given its notable benefits for industrial steel 3D printing, beam shaping capabilities are being developed and commercialized by a number of gamers within the analysis and LPBF 3D printing spheres. In 2024, German analysis group Fraunhofer Institute for Laser Know-how ILT showcased its new 3D printing beam shaping know-how. Working with the Chair of Know-how of Optical Techniques (TOS) at RWTH Aachen College, the brand new platform, the Fraunhofer workforce is creating a take a look at system for investigating complicated laser beam profiles.

This platform can create personalized beam profiles for laser powder mattress fusion (LPBF) 3D printing, enhancing half high quality, course of stability and productiveness, whereas minimizing materials waste.

In 2022, Equispheres and Aconity3D used laser beam-shaping 3D printing to realize construct charges practically 9 occasions larger than business norms. Equispheres’ NExP-1 aluminum powder was used with Aconity3D’s AconityMIDI+ LPBF 3D printer to unlock speeds exceeding 430 cm3/hr for a single laser.

The system was modified to make use of a PG YLR 3000/1000-AM laser with beam-shaping capabilities. By utilizing a formed beam over a zoomed Gaussian profile, the workforce lowered overheating and mitigated spatter formation throughout high-speed 3D printing.

Take the 3DPI Reader Survey — form the way forward for AM reporting in underneath 5 minutes.

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to maintain up with the newest 3D printing information.

You may as well observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

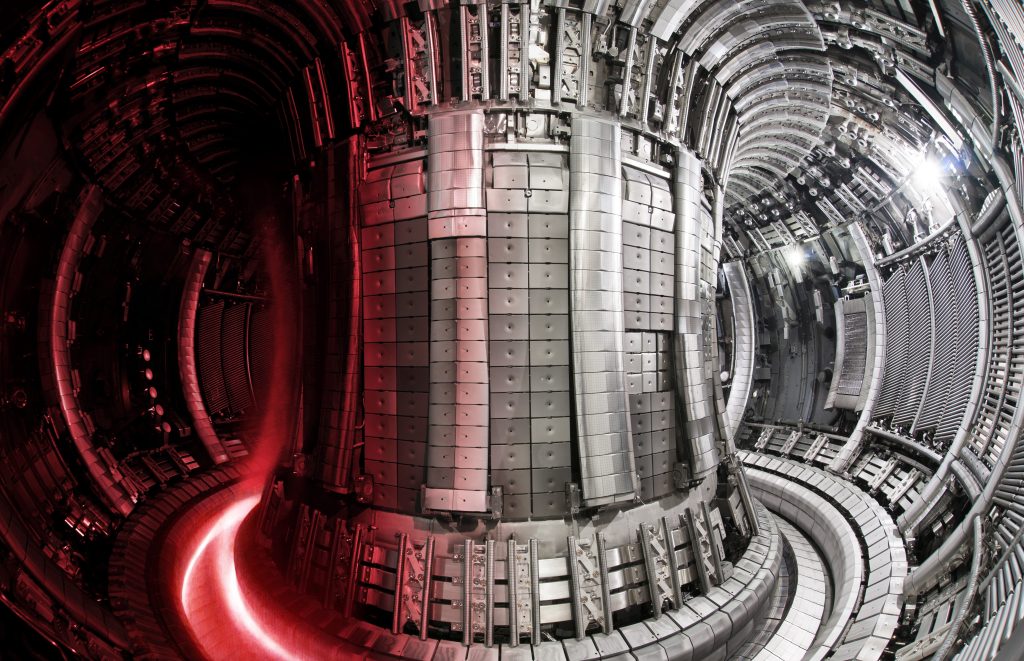

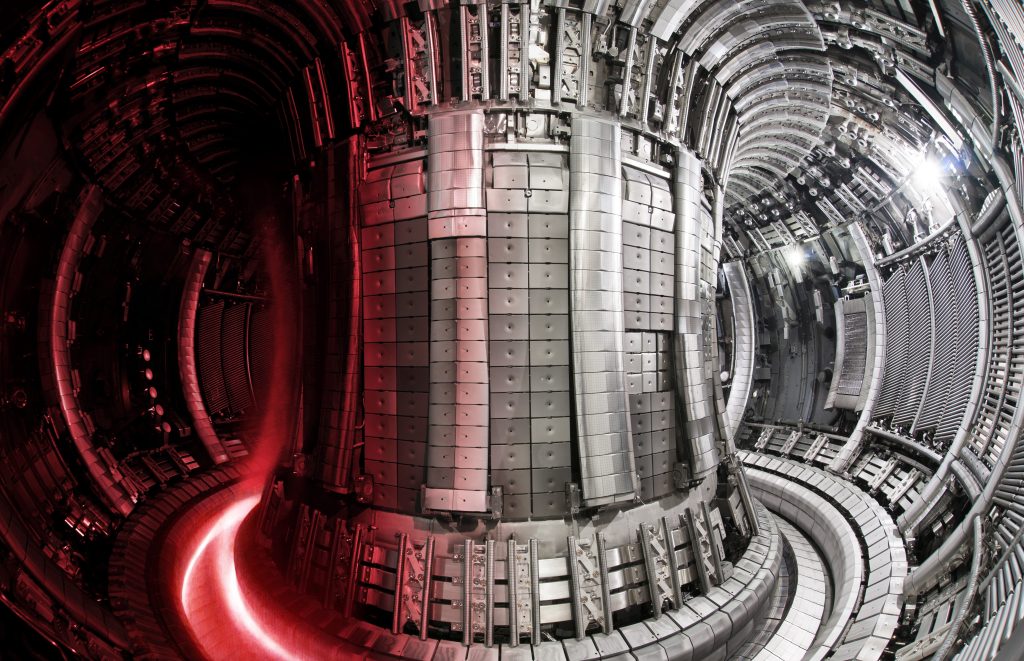

Featured picture reveals JET inside with tremendous imposed plasma. Picture through UK Atomic Power Authority.