A brand new examination of Apple companion TSMC’s Arizona facility shines a highlight on how the U.S. wager on home chipmaking is colliding with labor shortages, value overruns, and world dependencies.

Simply exterior Phoenix, a smooth, high-security facility is taking form. Often known as Fab 21, the positioning is operated by Taiwan Semiconductor Manufacturing Firm (TSMC) and can quickly be probably the most superior chipmaking amenities on the planet.

The microscopic transistors produced right here will energy Apple units, synthetic intelligence techniques and important infrastructure, representing a major shift of superior know-how manufacturing to American soil.

TSMC presently makes about 90% of the world’s most superior semiconductors, practically all of them in Taiwan. That long-standing reliance is now being reexamined amid world provide disruptions and rising tensions within the Asia-Pacific.

Engineering precision at tiny ranges

Inside Fab 21 as reported by the BBC, employees function in one of many cleanest environments on Earth. Clad in full-body protecting gear, they transfer by means of sealed clear rooms the place even a single mud particle may destroy a complete silicon wafer.

Every wafer takes over 3,000 exact steps to finish and may comprise lots of of chips, every with tens of billions of transistors. One of many first wafers produced on the web site featured 4-nanometer chips holding as much as 14 trillion transistors per chip, in keeping with TSMC.

These chips are fabricated utilizing excessive ultraviolet gentle, a course of involving plasma generated from molten tin and bounced by means of precision optics. The equipment required is constructed by ASML, a Dutch firm that provides the one lithography techniques able to producing these superior nodes.

TSMC replicated a lot of its Taiwan manufacturing surroundings in Arizona, however the complexity of the method means the US nonetheless depends closely on overseas gear, supplies and experience.

Controversies and rising pains

The Arizona plant hasn’t progressed with out friction. Development delays and price overruns pushed again preliminary manufacturing to 2025, with a second 2-nanometer fab now focused for 2028.

In 2023, TSMC flew in lots of of engineers from Taiwan to maintain the timeline on monitor. US labor unions criticized the transfer, arguing that the corporate had not carried out sufficient to coach native employees.

Taiwanese employees delivered to the US have reported challenges adjusting to native situations, from language obstacles to regulatory complexity. Some describe lengthy hours and stress to satisfy aggressive targets underneath unfamiliar guidelines.

Behind the scenes, executives have voiced frustration with US allowing processes, labor availability and cultural variations in office norms. Constructing chips at scale in America has confirmed far dearer than in Taiwan, regardless of federal subsidies.

Formally, Taiwan’s authorities helps TSMC’s world enlargement. Privately, there’s concern. Taiwan’s dominance in semiconductors, typically known as the “Silicon Protect,” is seen as important leverage in deterring Chinese language aggression.

Shifting high-end manufacturing abroad could scale back that leverage and undermine the island’s geopolitical relevance.

Some in Taipei have warned towards letting the US or different allies “hole out” Taiwan’s tech benefit. Others view diversification as needed insurance coverage towards provide chain shocks or army threats.

Commerce stress and federal subsidies formed the transfer

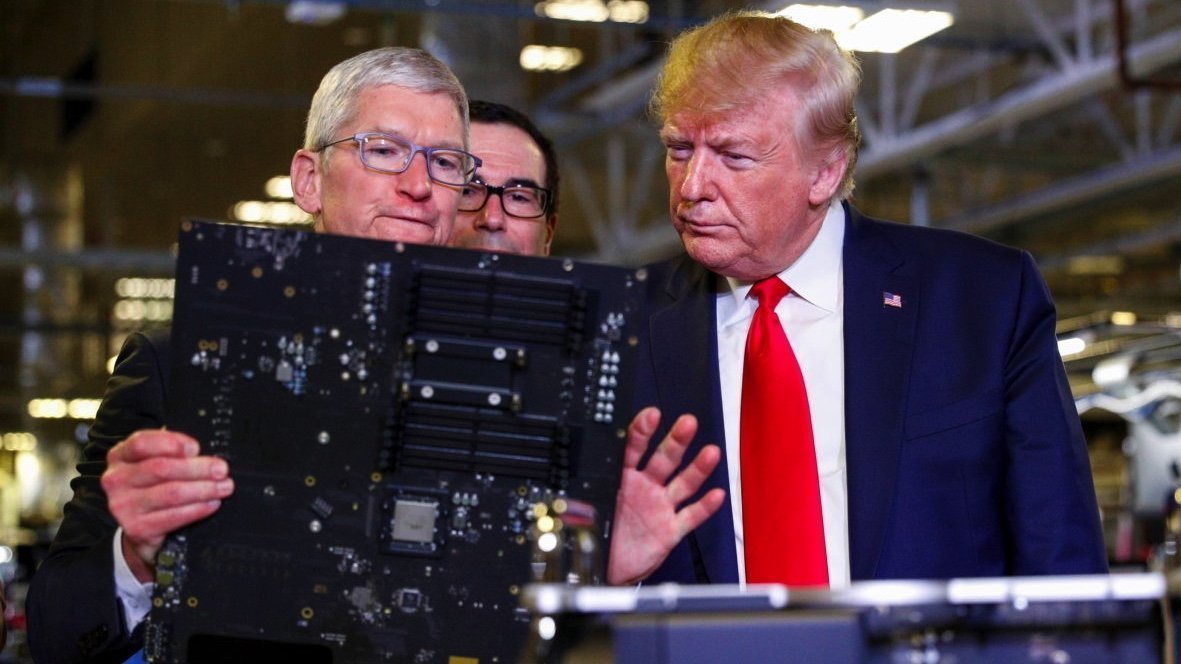

President Donald Trump ceaselessly cited TSMC’s US funding as proof that his tariff threats labored. His administration pushes to cut back US dependence on Asian manufacturing, utilizing commerce stress to encourage reshoring.

Former President Joe Biden centered on subsidies and long-term industrial planning. The CHIPS and Science Act, signed into legislation in 2022, presents tens of billions in funding and tax incentives.

TSMC’s Arizona undertaking is the biggest overseas beneficiary, with $40 billion dedicated throughout two building phases. Section one is anticipated to supply chips in 2025.

Regardless of the political divide, each administrations have handled semiconductor independence as a bipartisan precedence. TSMC’s presence in Arizona is the centerpiece of that effort.

Semiconductors are not only a tech business concern. They’re now seen as the inspiration of financial safety, synthetic intelligence management and nationwide protection.

The Arizona fab is a central piece of the US technique to localize chip manufacturing, scale back dependence on Taiwan and keep forward of China in superior computing.

Bringing TSMC to the US provides American companies nearer entry to their most important elements. It additionally provides Washington a foothold in reshaping world provide chains round trusted companions.

However the undertaking’s significance runs deeper than company logistics.

Strategic chips for the AI period

The Arizona facility is producing chips not just for smartphones and laptops but additionally for synthetic intelligence, cloud computing and protection purposes. Corporations like Apple and Nvidia have confirmed plans to make use of chips from Fab 21 in upcoming US-bound merchandise.

Each the Trump and Biden administrations have moved to dam China’s entry to those applied sciences. The US has restricted exports of ASML lithography instruments and banned corporations like Huawei from buying high-end chips.

Nonetheless, China is racing to catch up. US restrictions have pushed Beijing to go full pace forward. That is a part of why leaders in each events proceed to push for home capability.

Waiting for a fragmented future

TSMC’s Fab 21 is a part of a broader reshaping of the worldwide semiconductor map. Intel is constructing new fabs close by. Samsung is increasing in Texas. Arizona, already a hub for aerospace and protection, is changing into a important node in America’s plan to regain management in chip manufacturing.

However world interdependence won’t disappear in a single day. Key elements nonetheless come from Japan, Germany and the Netherlands. Engineers from Taiwan proceed to coach the US workforce. Even the clear room clothes are sometimes imported.

As geopolitical competitors escalates, the US faces a fragile balancing act. It should rebuild strategic capability whereas staying related to a worldwide innovation community. The Arizona fab could not make the US self-sufficient, however it’s a foundational step towards larger resilience.