Ahead-looking: As InventWood prepares to deliver its first batches of Superwood to market, it stands as a testomony to what can occur when scientific innovation meets entrepreneurial willpower. If profitable, Superwood might mark a turning level within the quest for greener, stronger, and extra stunning buildings.

What started as a laboratory experiment on the College of Maryland is now poised to considerably affect development practices. InventWood, a startup spun out of the college, is making ready to launch a brand new materials referred to as Superwood – a wood-based product engineered to have a strength-to-weight ratio almost ten instances larger than metal, but lighter and extra sustainable.

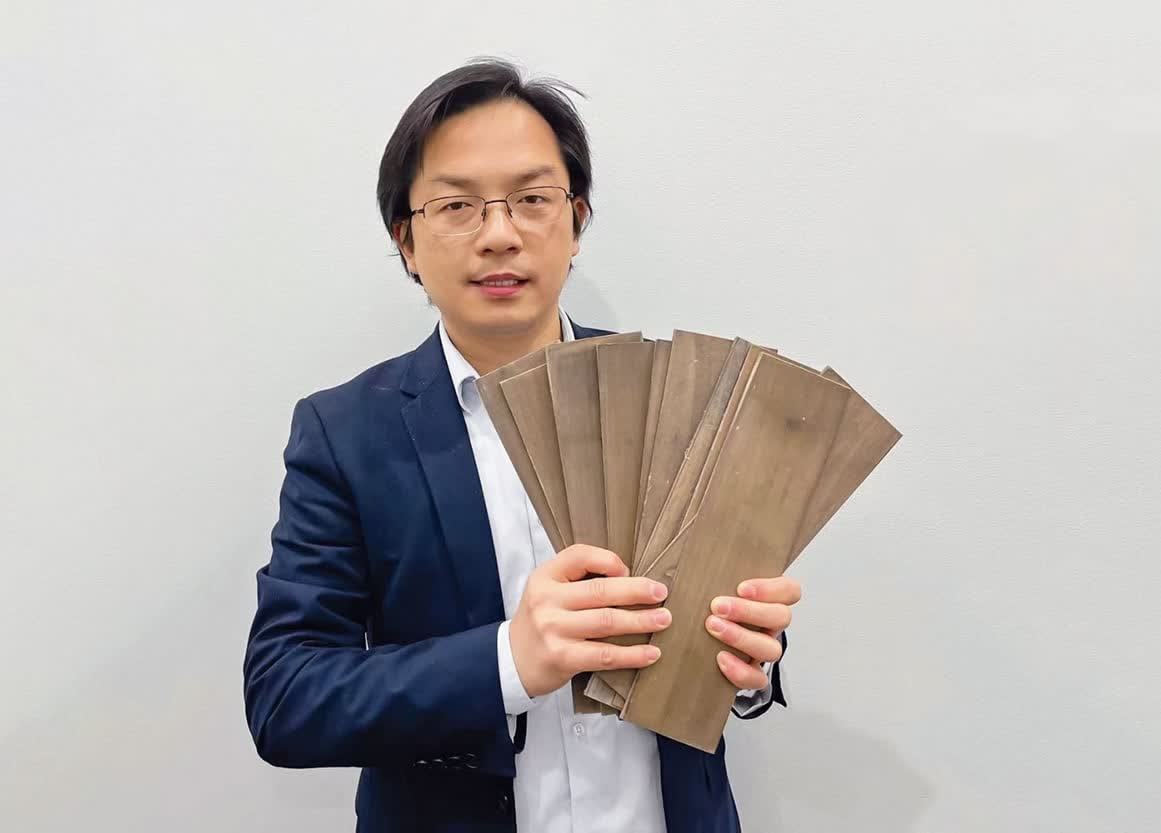

The story started in 2018, when Dr. Liangbing Hu, a supplies scientist on the College of Maryland, developed a patented method that transforms unusual timber into a fabric as much as 12 instances stronger and 10 instances more durable than its authentic kind.

As an alternative of letting the invention languish in tutorial obscurity, Dr. Hu additional refined his method, dramatically decreasing the manufacturing time from over every week to just some hours.

Recognizing its industrial potential, Dr. Hu licensed the know-how to InventWood, which is now led by CEO Alex Lau. With $15 million lately secured in a Collection A funding spherical (a part of greater than $50 million raised to this point), the corporate is making ready to open its first industrial manufacturing facility in Frederick, Maryland. Shipments of Superwood are scheduled to start within the third quarter of 2025.

Superwood’s innovation lies in its molecular engineering. The method begins with unusual wooden, which is usually composed of cellulose and lignin. By selectively eradicating sure parts and making use of “meals business” chemical substances, InventWood strengthens the cellulose fibers, then compresses the fabric to extend the hydrogen bonds between molecules.

This new materials isn’t just sturdy, it is also extremely purposeful. Superwood is resistant to fireplace, water, rot, and pests. It retains the pure heat, texture, and fantastic thing about wooden, and with some polymer remedy, can be utilized for outside functions like siding, decking, and roofing.

Initially, InventWood will concentrate on producing facade supplies for industrial and high-end residential buildings. However the firm’s ambitions go additional. Lau envisions a future the place structural beams and different constructing parts are constituted of Superwood, providing architects and builders a fabric that’s not solely high-performing but additionally environmentally accountable.

The environmental advantages are vital. The development business is a serious contributor to world carbon emissions, largely as a result of its reliance on concrete and metal. By providing a domestically sourced, sustainable different, InventWood goals to scale back the business’s carbon footprint whereas supporting American manufacturing and native economies.

The corporate has additionally fashioned a strategic partnership with Intectural, a number one distributor of architectural supplies, to speed up Superwood’s adoption throughout North America.

InventWood’s progress has attracted assist from each private and non-private sectors, together with the US Division of Power, the Division of Protection, and several other climate-focused funding teams. Environmentalist and entrepreneur Paul Hawken has referred to as Superwood “a unprecedented breakthrough that exalts the genius of the pure world,” predicting it should play a pivotal position in the way forward for world development.