Once you wish to make massive 3D prints as a result of STL information are of the best high quality, like those you could find on Gambody market, and let you upsize your venture to life-size or much more, it’s best to uncover the principle secrets and techniques of large-scale 3D printing. Do you wish to set up a large Millennium Falcon in your lounge? Do you dream of hanging a life-size Tyrannosaur Rex bust in your little one’s bed room?

No matter your goals are, maintain studying to study the steps you’ll should take to realize them.

Giant-Scale 3D Printing

Increasingly hobbyists get pleasure from massive 3D printing and work on large fashions that received’t match on a shelf and sometimes don’t match on the common printer mattress. The Premium sector on Gambody 3D printed market is crammed with unimaginable provides, and every one has been examined to print with out errors and boasts such wonderful particulars that upscaling most figures and fashions for 3D printing is an enormous should!

To start working in your massive 3D prints, you don’t have to modify your printer instantly and purchase a large-format machine. As an alternative, it’s best to study extra about 3D printing massive objects on a regular desktop printer construct plate. One of many strategies is slicing or splitting the mannequin in Fusion 360, Blender, Autodesk Maya 3D, Bambu Studio, Meshmixer, or a distinct software program. Let’s look them up extra carefully.

Learn additionally: Over 100 Enjoyable 3D Printer Initiatives.

Break up STL Software program

Once you don’t have a 3D printer for big objects, akin to gMax 2 or extra reasonably priced FLSUN V400 3D printer, you could learn to break up STL information to suit in your printer’s mattress.

You possibly can strive Fusion 360, Meshmixer, Tinkercad, Blender, Cura break up mannequin technique, and so on. Completely different slicers have distinctive options and instruments that require time to develop into acquainted with and loads of apply to develop into a professional. In large-scale 3D printing, by splitting STL information, it’s best to study to make straight cuts to separate an enormous half into smaller items or add aligners to observe the venture’s creases. Irrespective of what number of components you propose to create, it’s best to determine them with numbers or letters that can assist you with mannequin meeting.

Is it an advanced job? Nothing is not possible if you need to work on huge 3D prints with no matter machine model you personal. Let’s element how precisely you’ll be able to break up a 3D mannequin for printing.

Learn additionally: Noble Life-Measurement Groot 3D Print by Jose Antonio.

Easy methods to Break up a 3D Mannequin for Printing

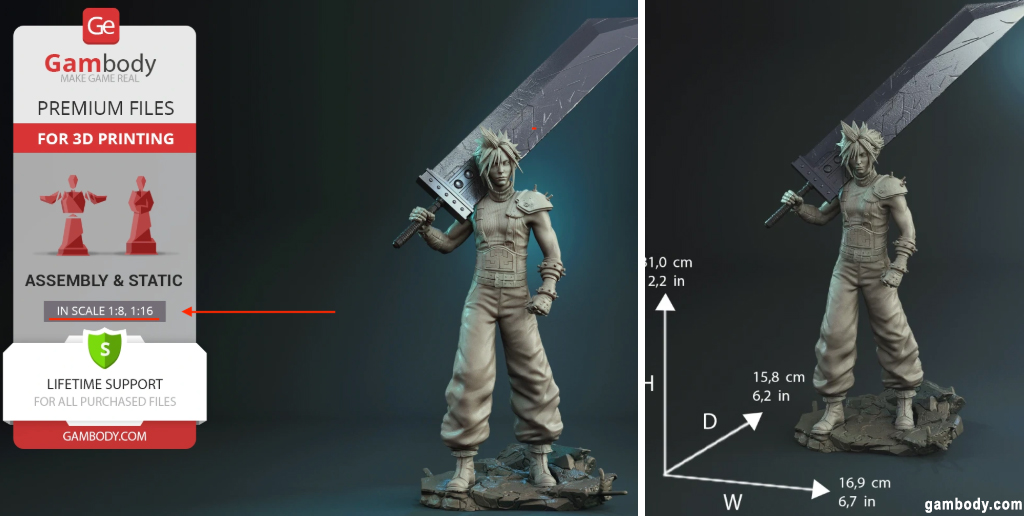

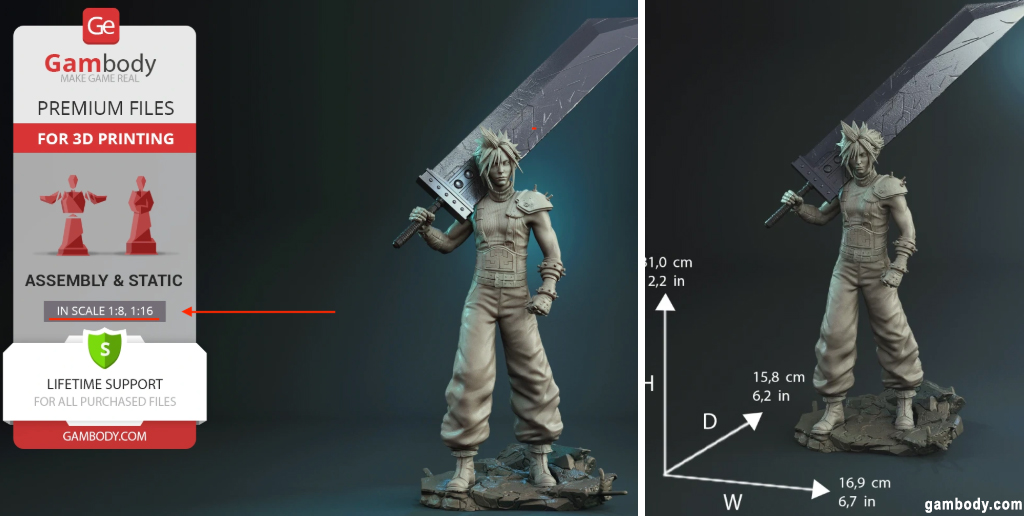

Take a better have a look at the STL file you want to break up (Gambody will show the steps in a number of slicers utilizing the Cloud Strife 3D printing mannequin, which STL information you may as well obtain to recreate in life-size).

Common recommendation. In case your venture has many intricate particulars, keep away from slicing by them or too near them as a result of you’ll be able to injury the design. Keep in mind the potential splits and the way they’ll have an effect on the variety of helps you’ll have to make use of. The much less is one of the best.

It’s additionally finest to separate with angles or planes, contemplating the structural integrity of the 3D printing determine or mannequin. Don’t minimize on the thinnest factors, that are normally weak. The world the place you chop has to have sufficient floor, particularly if you need to assemble the components after the break up.

As you consider one of the best methods to separate STL, guarantee each bit can take probably the most of your 3D printer mattress. This manner, it can save you time, filament (or resin), and your nerves.

Learn additionally: Distinctive Life-Measurement Paul the Alien 3D Print: Interview with Michael Shaw on Making a Collectible Piece.

Shortly About Gambody Fashions

Once you flick thru Premium 3D Printing Fashions on gambody.com, you could find the exact measurement of each determine and mannequin, from the smallest elf to the largest demons and spacecraft. Thus, you’ll be able to upscale them to your wants. The fashions’ description pages and pictures have a grid and scale that may assist you determine your venture’s life-size dimensions.

To make massive 3D prints in an accurate life-size model, you could upscale all components of your mannequin to the identical scale. In our case, it’s important to upscale the Cloud Strife determine to eight occasions its authentic measurement (we use the FDM model). Gambody recommends you upscale FDM fashions to life-size variations except you want to obtain ready-to-print life-size initiatives akin to Spider-Man Recreation Suite or Robotic Maria.

It’s best to make use of a 3D printer with a minimal print quantity of 8.6 x 8.6 x 9.8 inches (220 mm x 220 mm x 250 mm) and work out the utmost measurement you’ll be able to print at a time.

Learn additionally: Fabulous Life-Measurement 3D Printed Mannequin for Recreation of Thrones Followers: Interview with Tatiana Rizou.

Autodesk Fusion 360

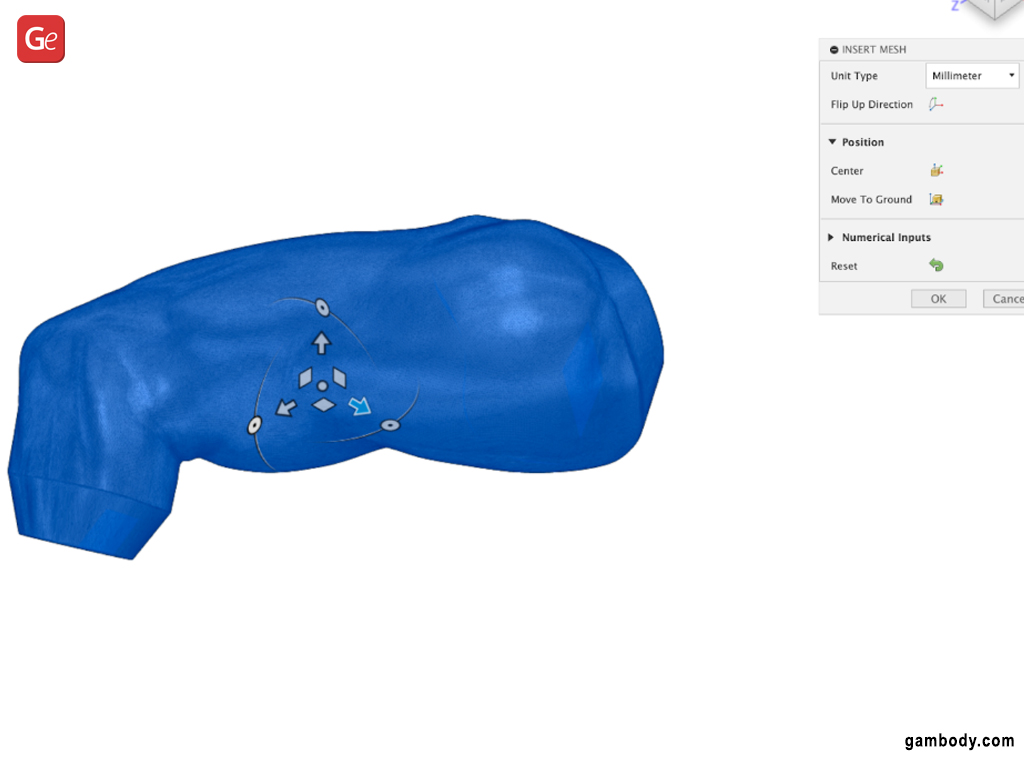

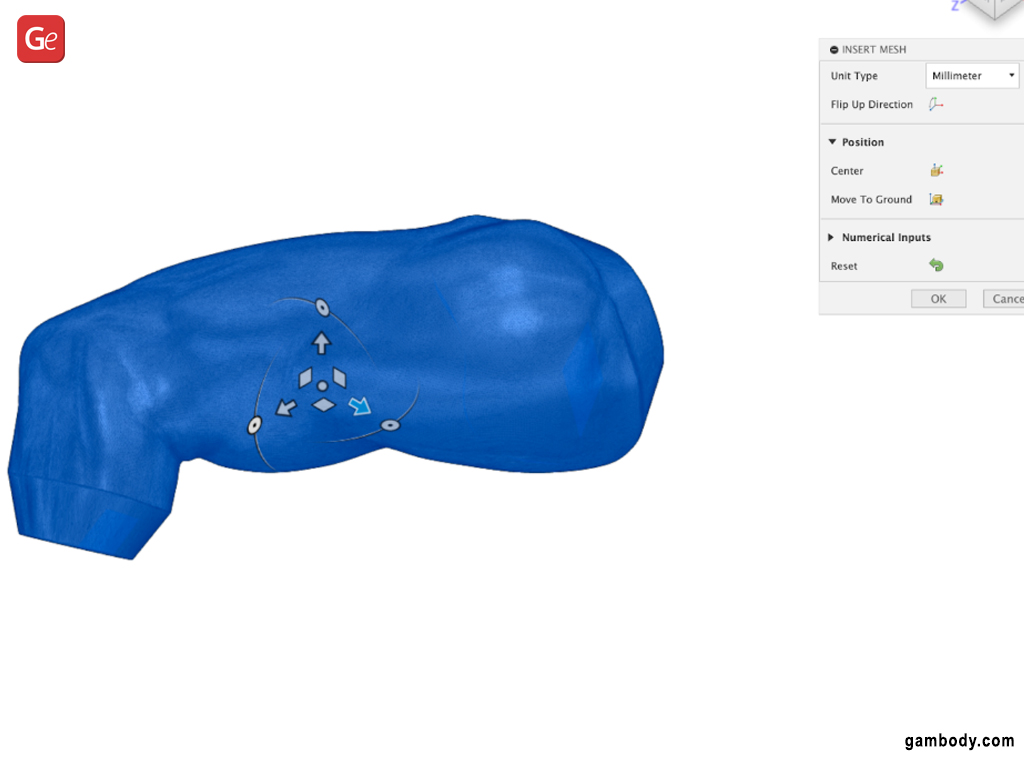

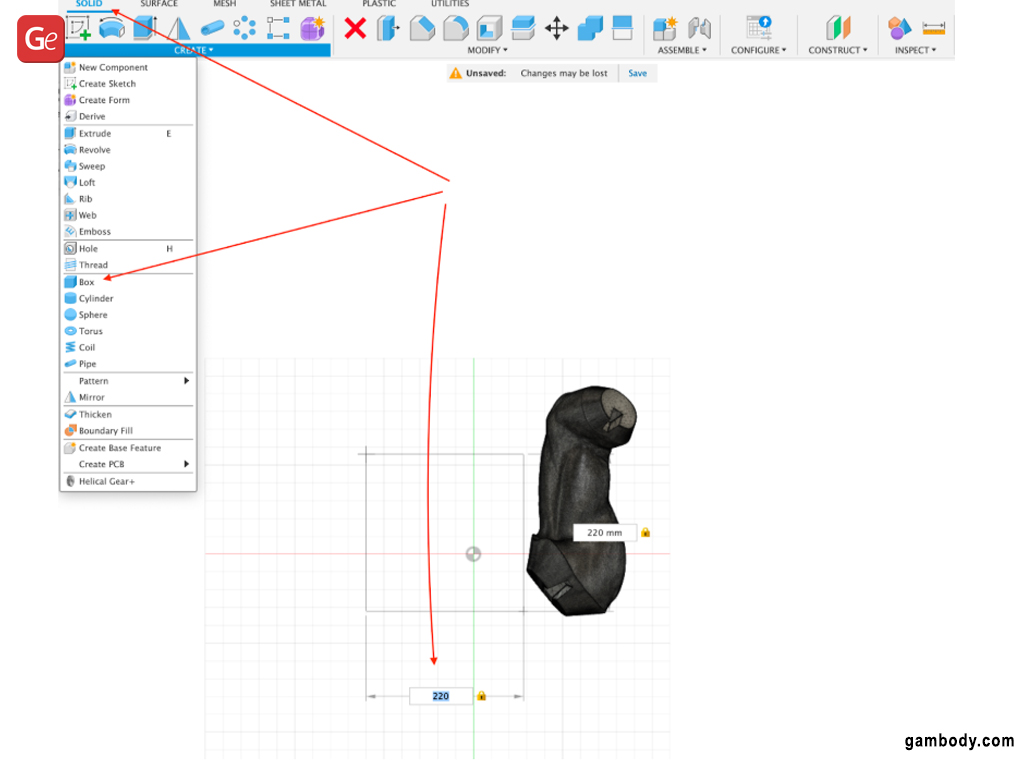

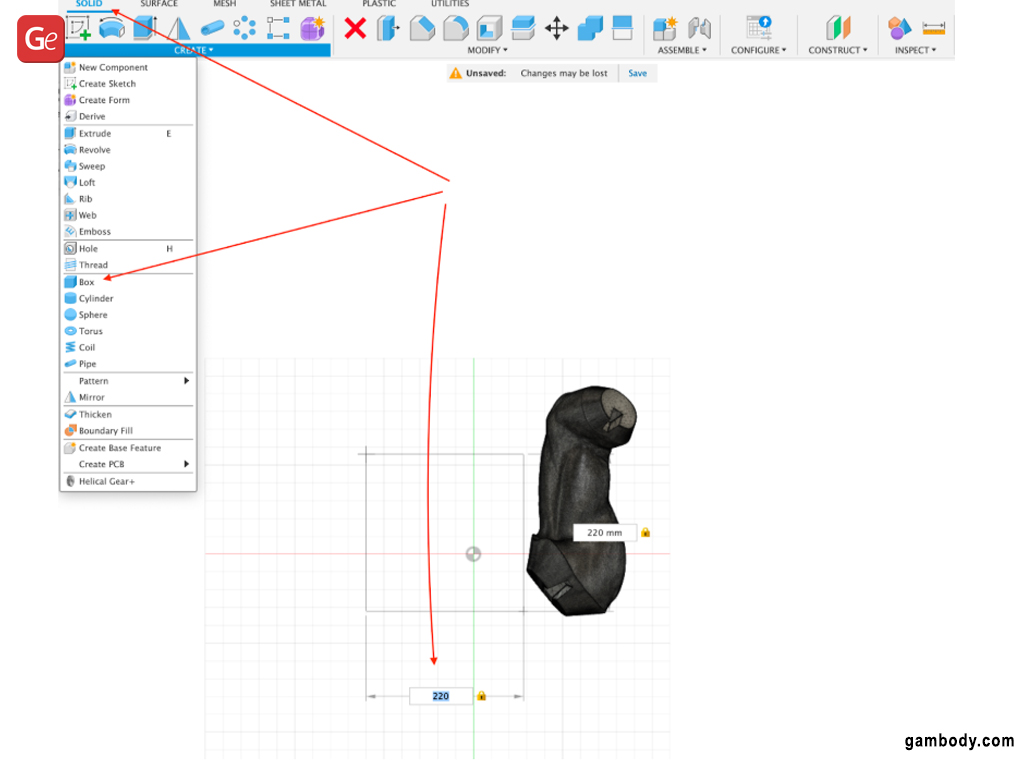

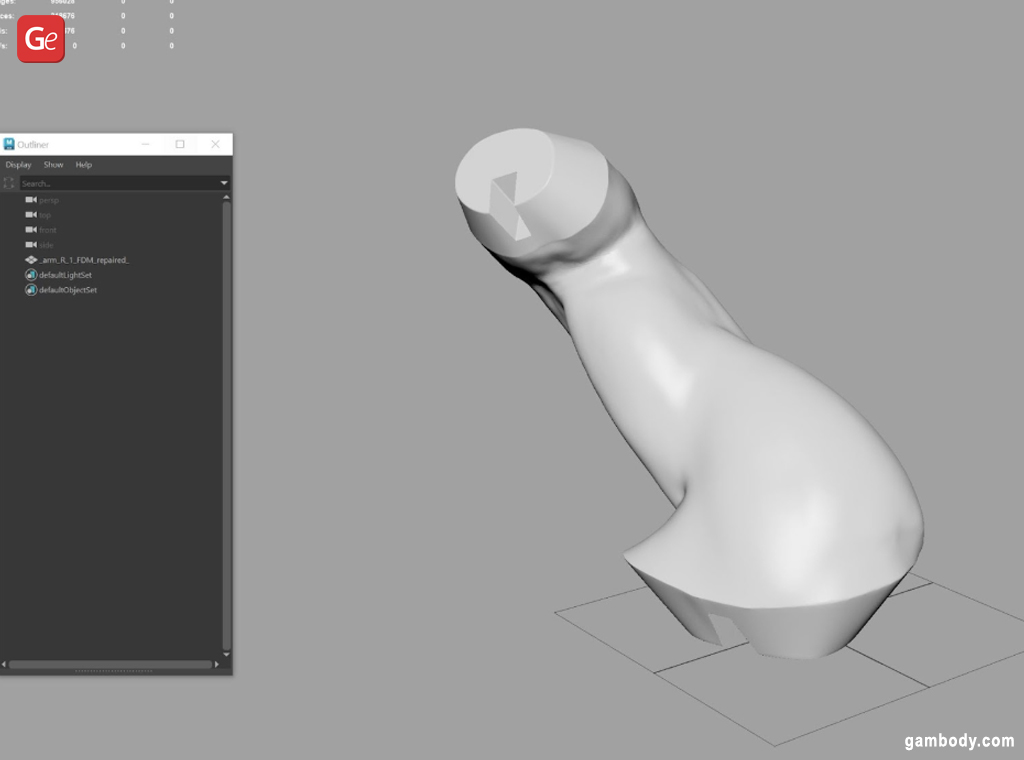

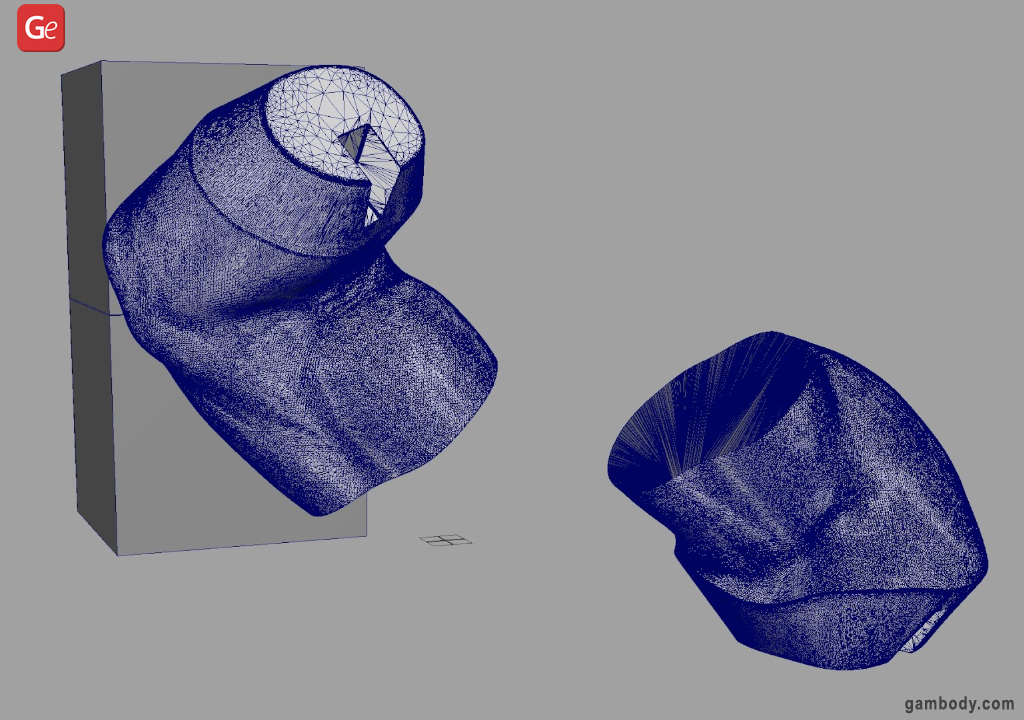

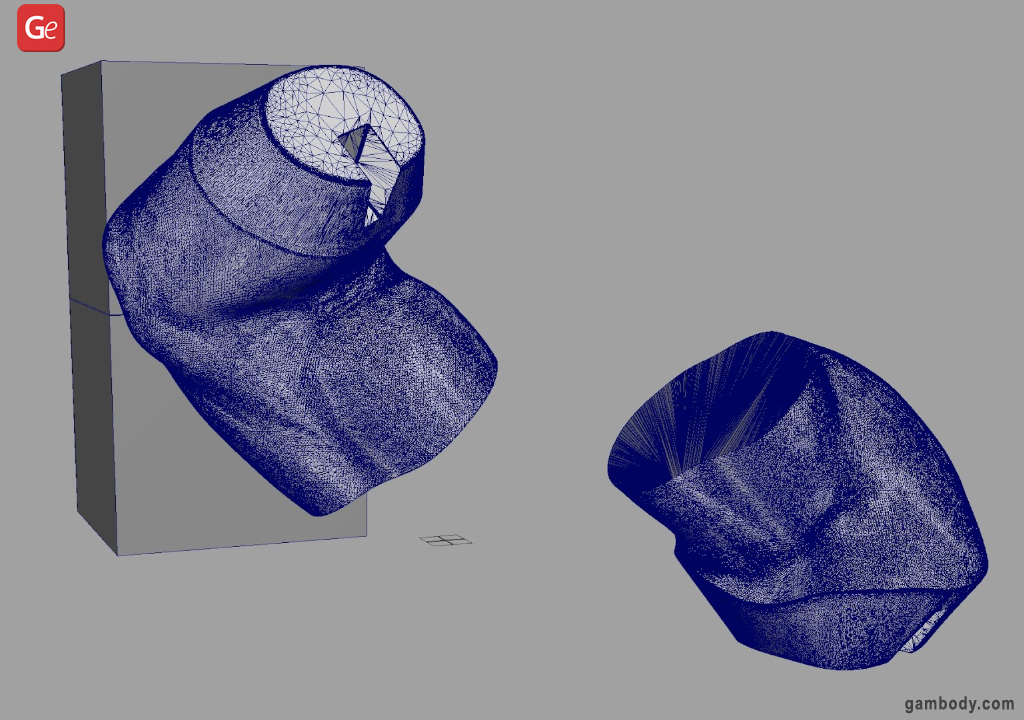

Autodesk Fusion (previously Autodesk Fusion 360) may be very widespread amongst hobbyists. You possibly can perceive the steps you typically have to take to separate STL in Fusion within the instance beneath. Let’s slice the hand of Cloud Strife, pretending you want to flip this determine into a big 3D print (life-size would look nice on this character, by the way in which!).

Step 1. Launch Autodesk Fusion and import the half as mesh. Place it on the mattress.

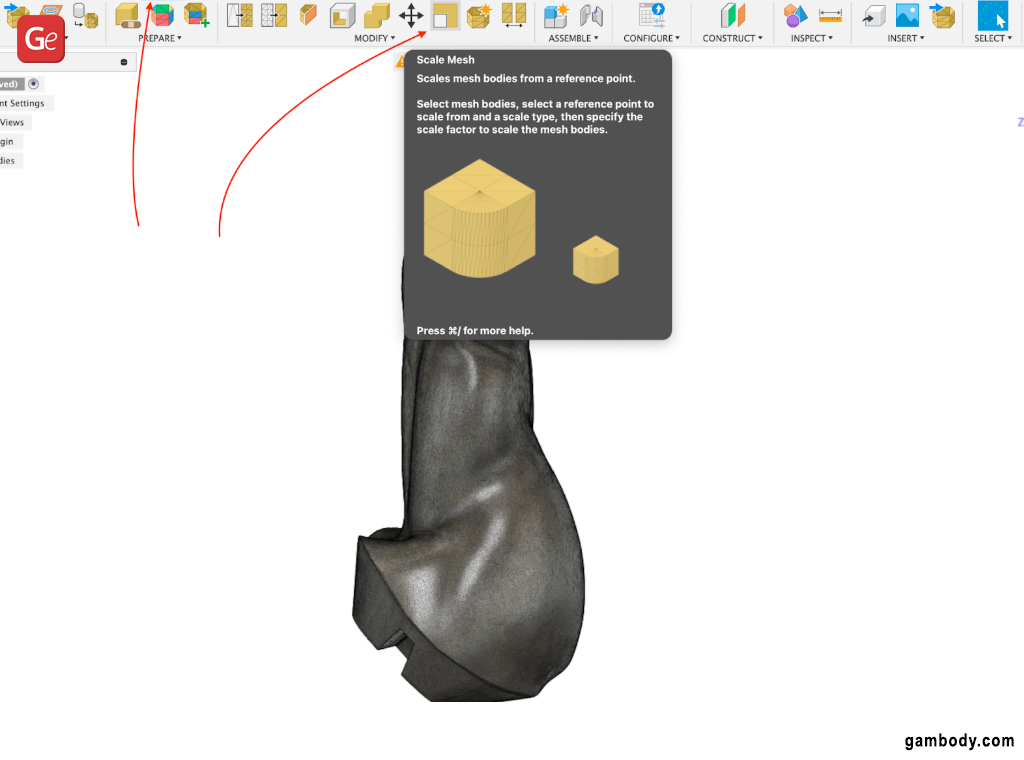

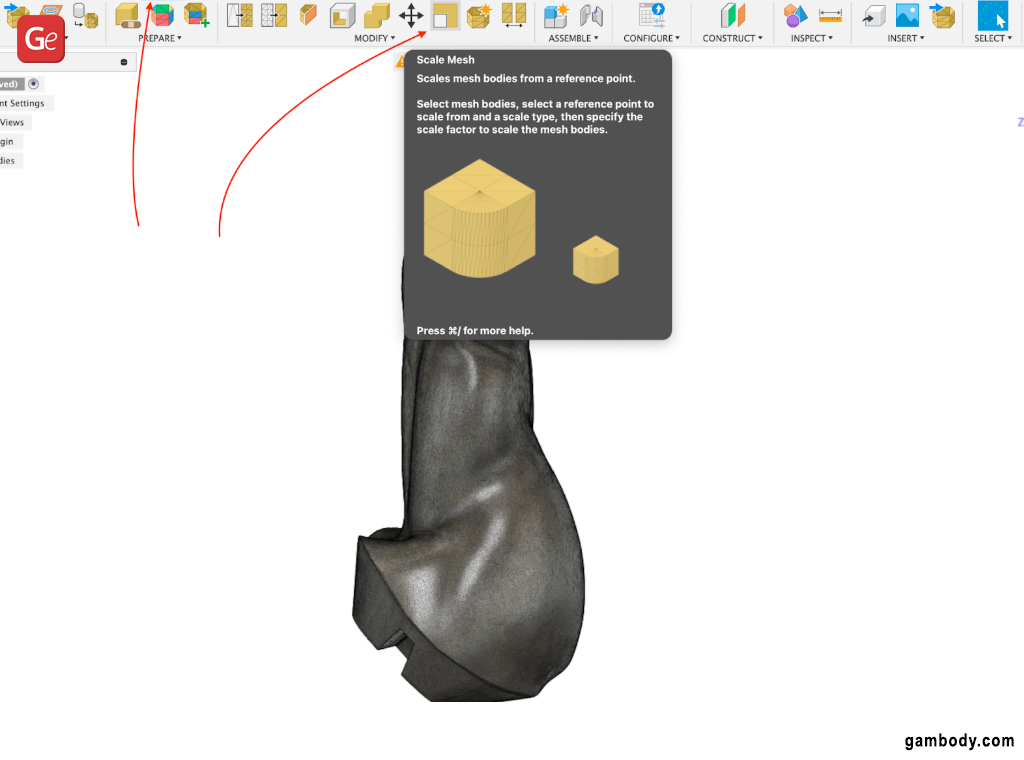

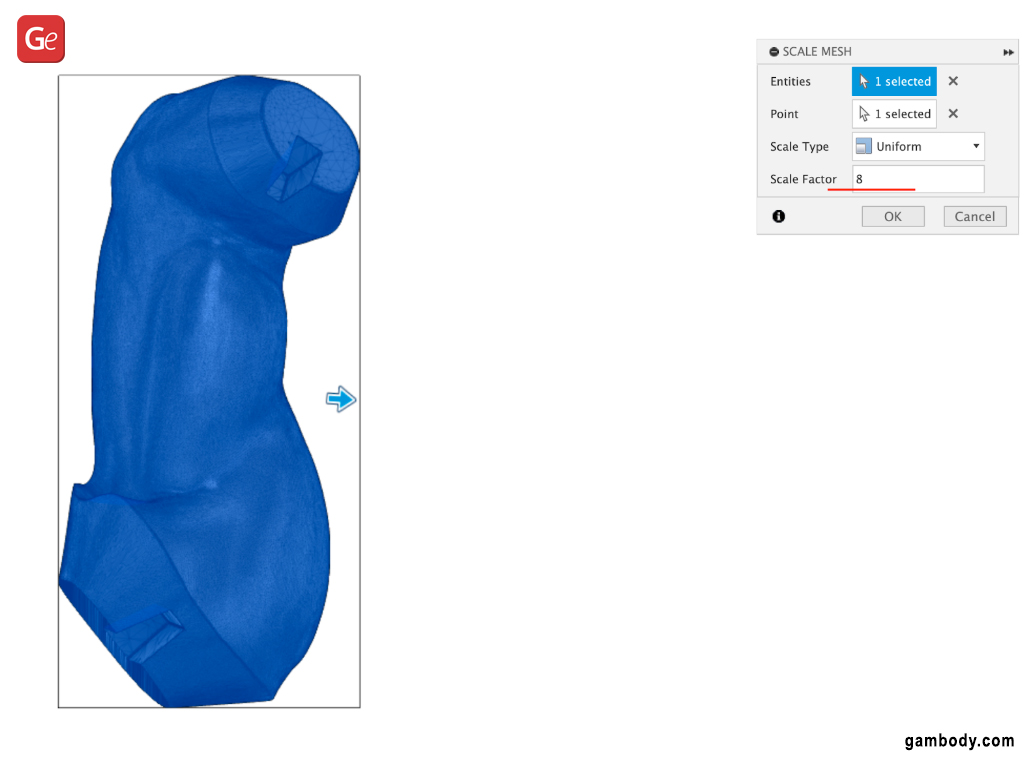

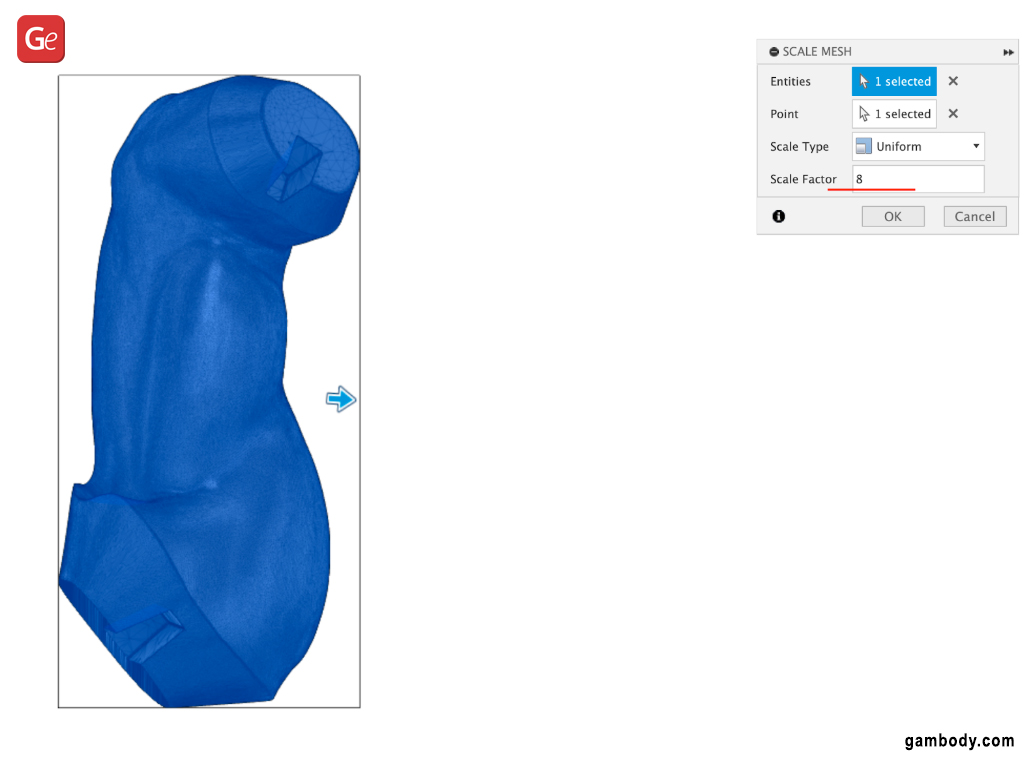

Step 2. Upscale it to eight occasions its authentic measurement by selecting the “Scale Mesh” parameter from the “Mesh” menu. Use the “Scale Issue” 8.

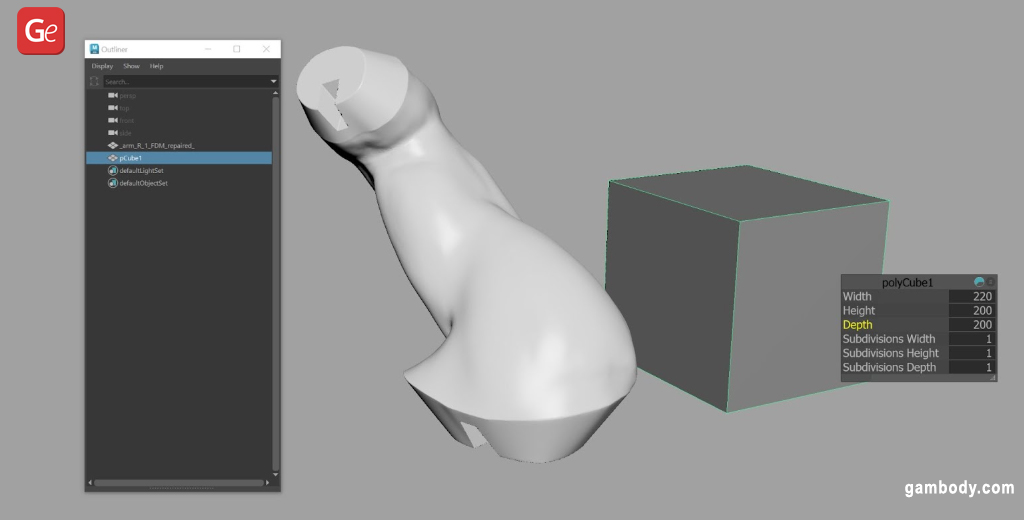

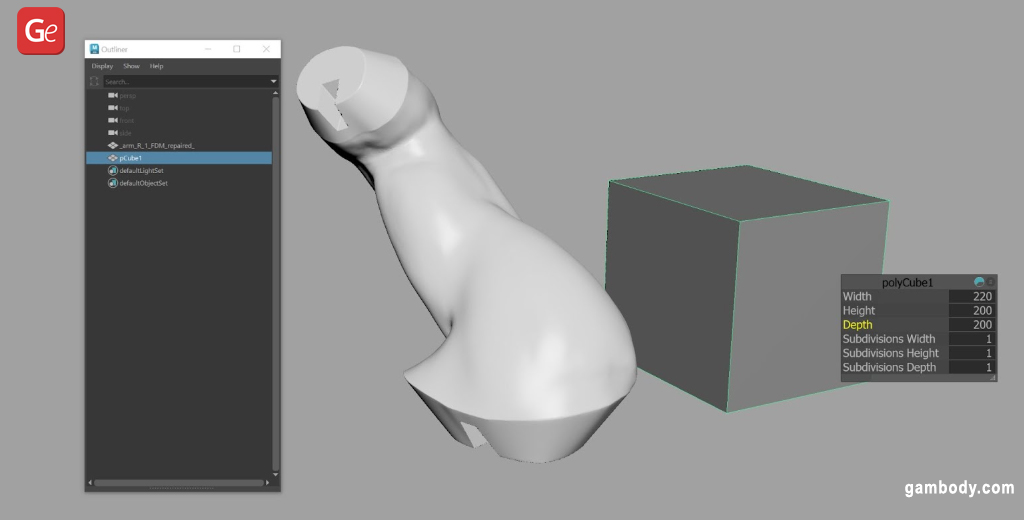

Step 3. Gambody advises you to create a strong field with the utmost measurement of your 3D printer mattress to keep away from upscaling the 3D printing figures means an excessive amount of.

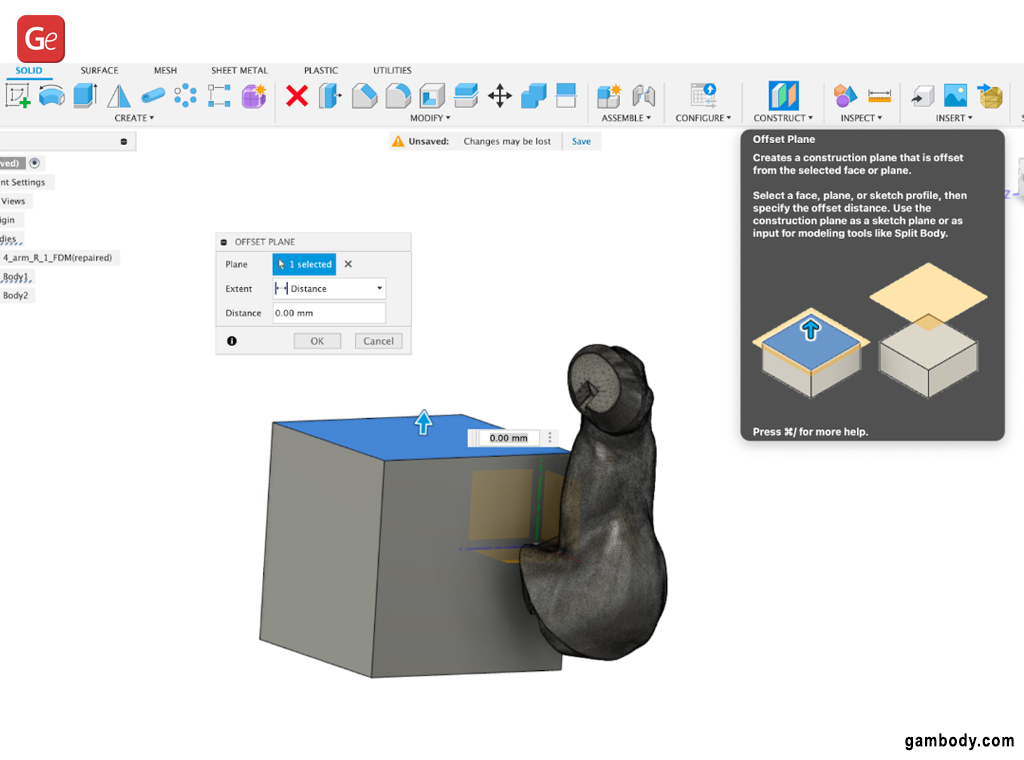

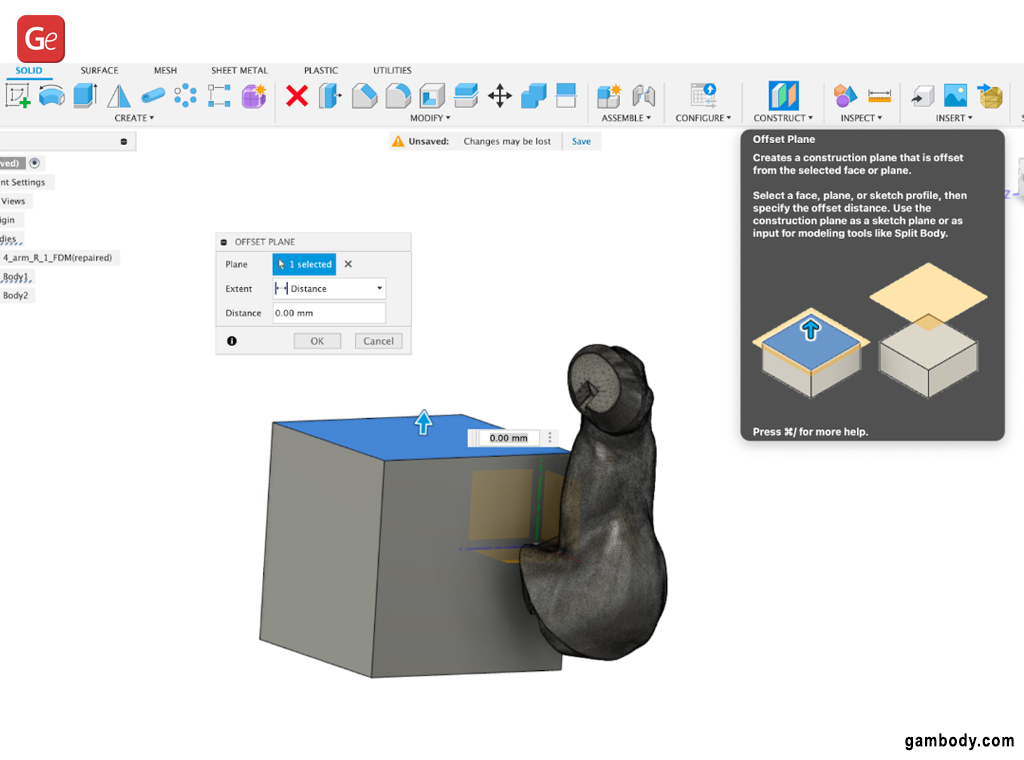

Step 4. Choose the airplane you want to use to separate STL. It will likely be simpler for those who select one of many dice faces for this job and make your offset airplane about 5 p.c smaller than the utmost measurement of the mannequin you’ll be able to match in your 3D printer mattress.

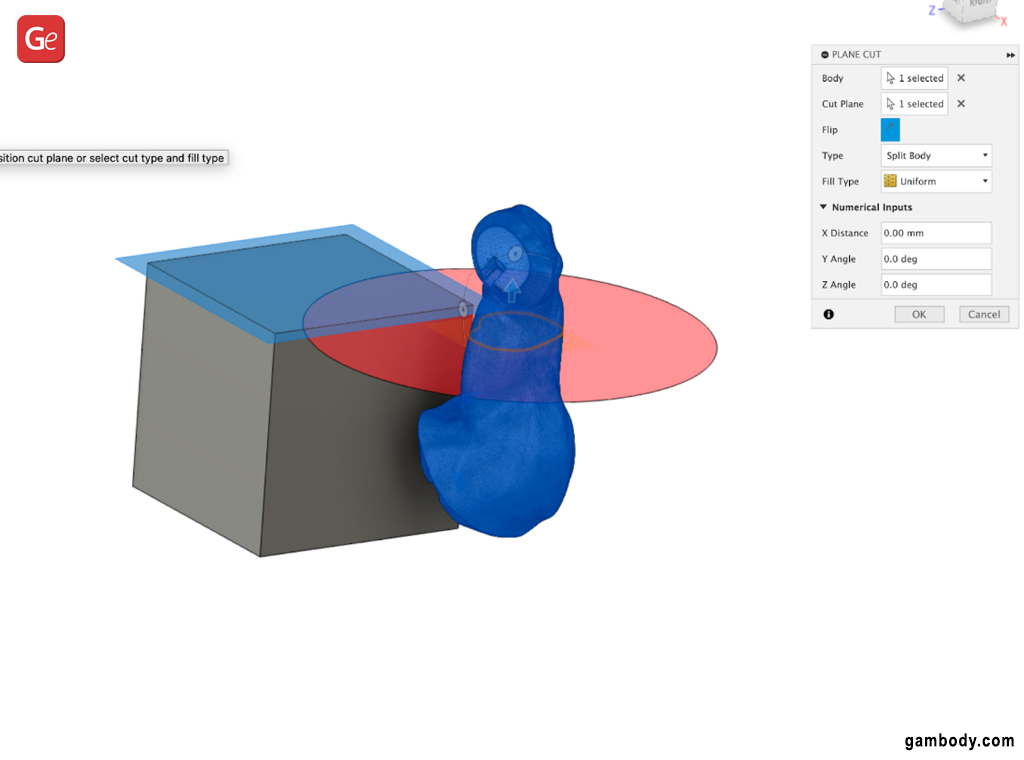

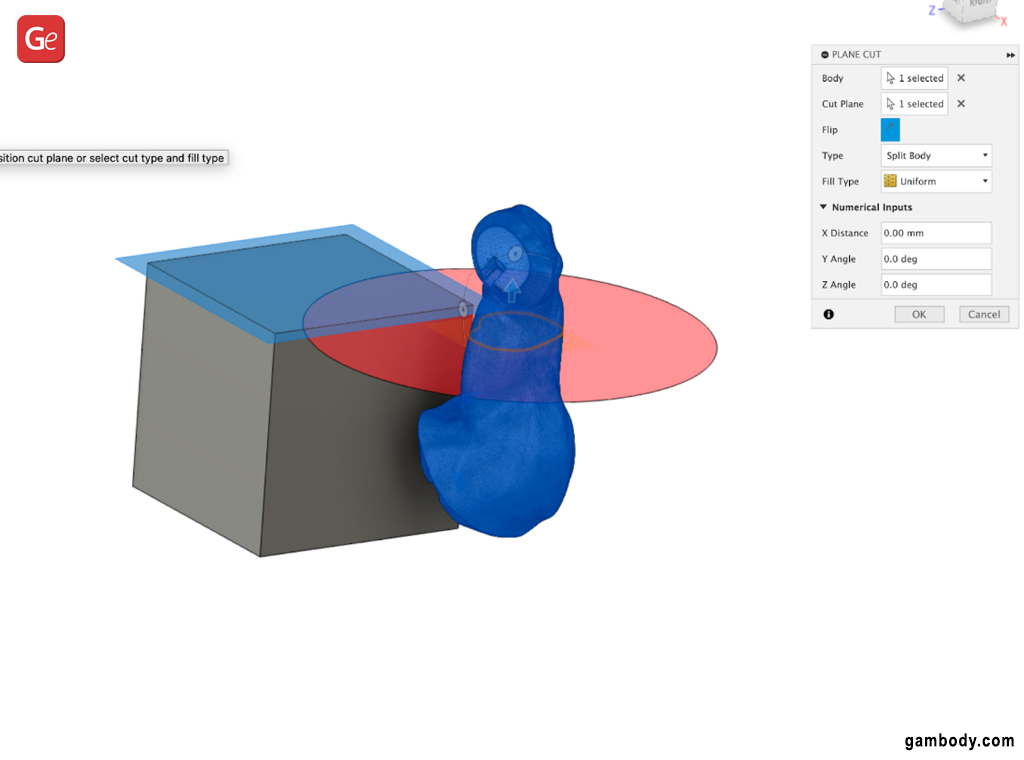

Step 5. Choose the 3D printing half and the minimize airplane. Fill out the parameters similar to within the picture beneath:

Step 6. Congratulations! You might be prepared to start out 3D printing massive components, and you should utilize Fusion 360 to chop an STL file in half.

Learn additionally: Free STL Editor: Easy methods to Edit and Restore STL Recordsdata (3D Fashions).

Bambu Studio

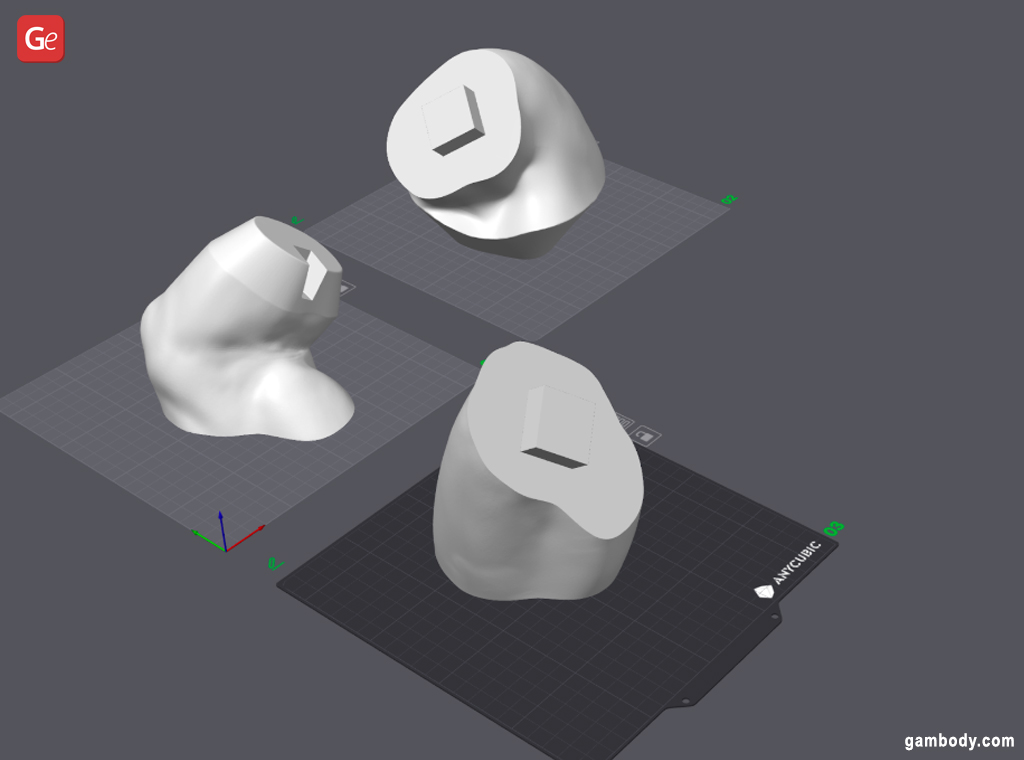

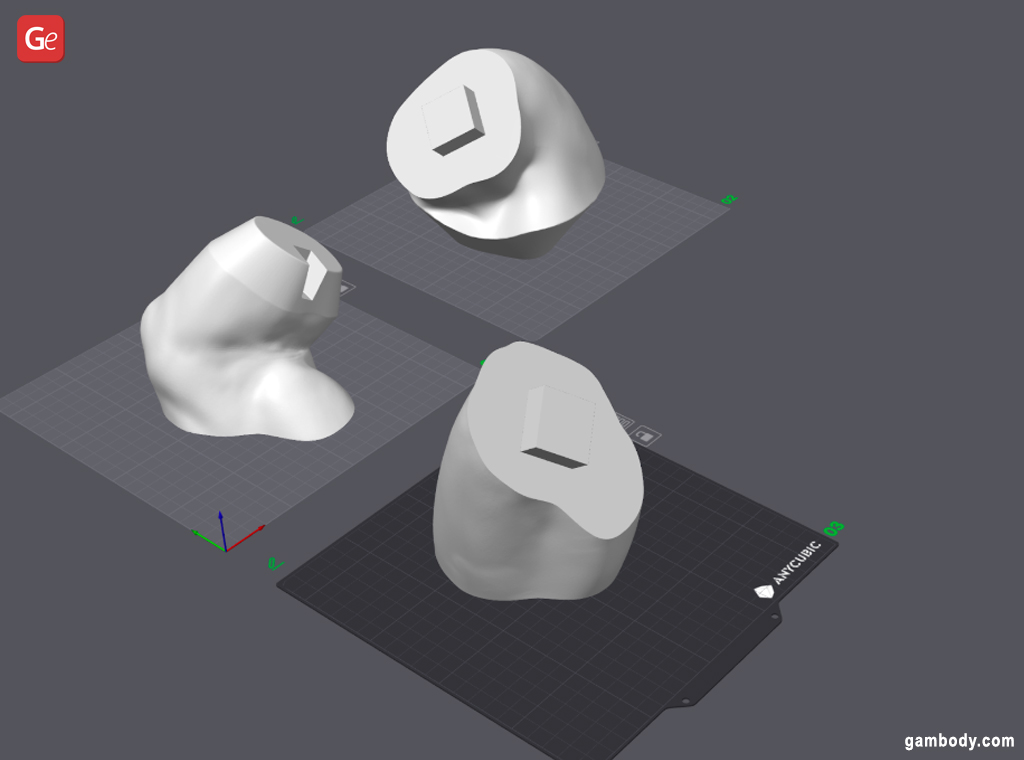

Let’s now break up STL into components utilizing Bambu Studio. This open-source slicer has many nice options. Cloud Strife’s hand is as soon as once more used for example of what it’s best to do to make life-size figures and fashions.

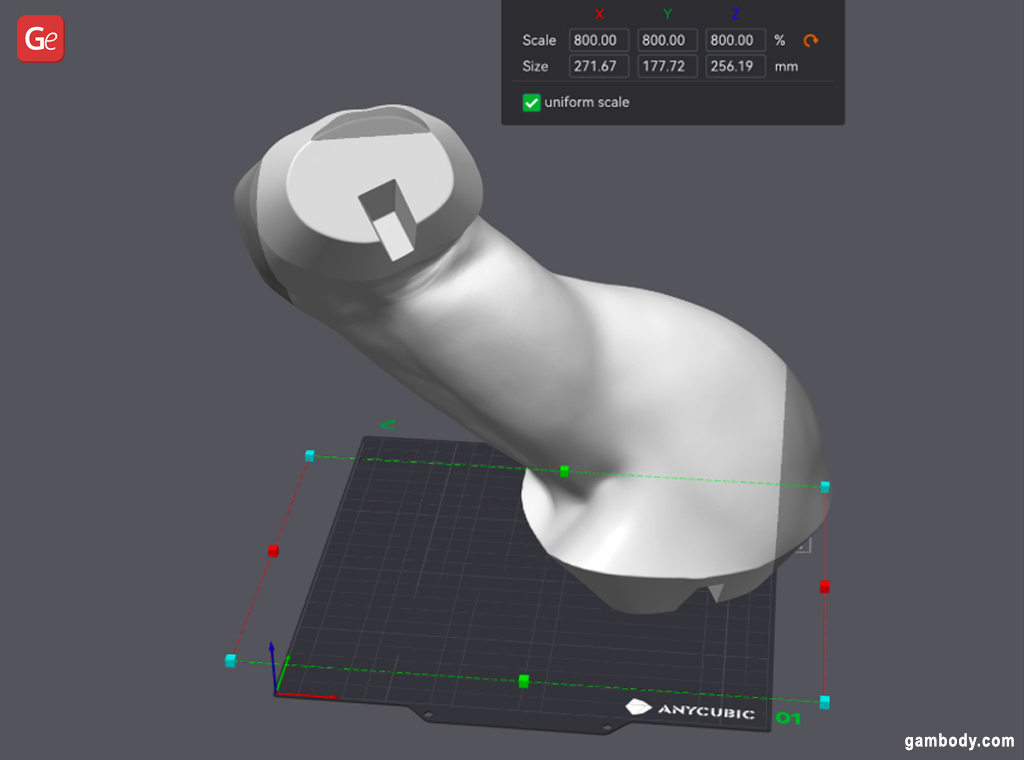

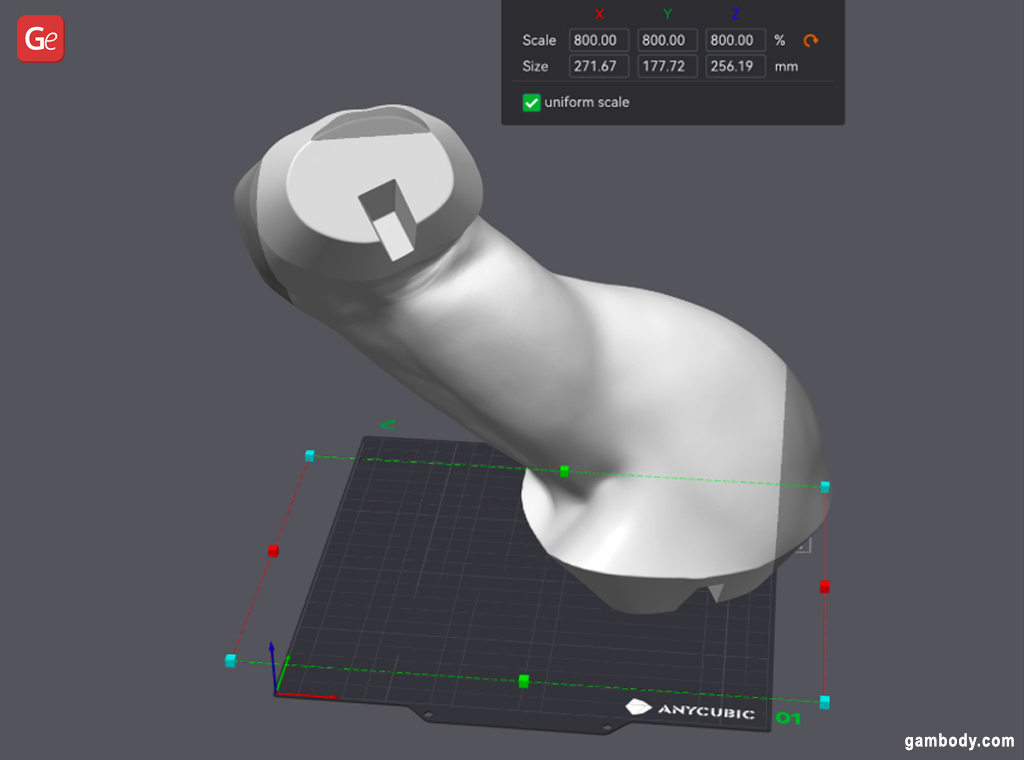

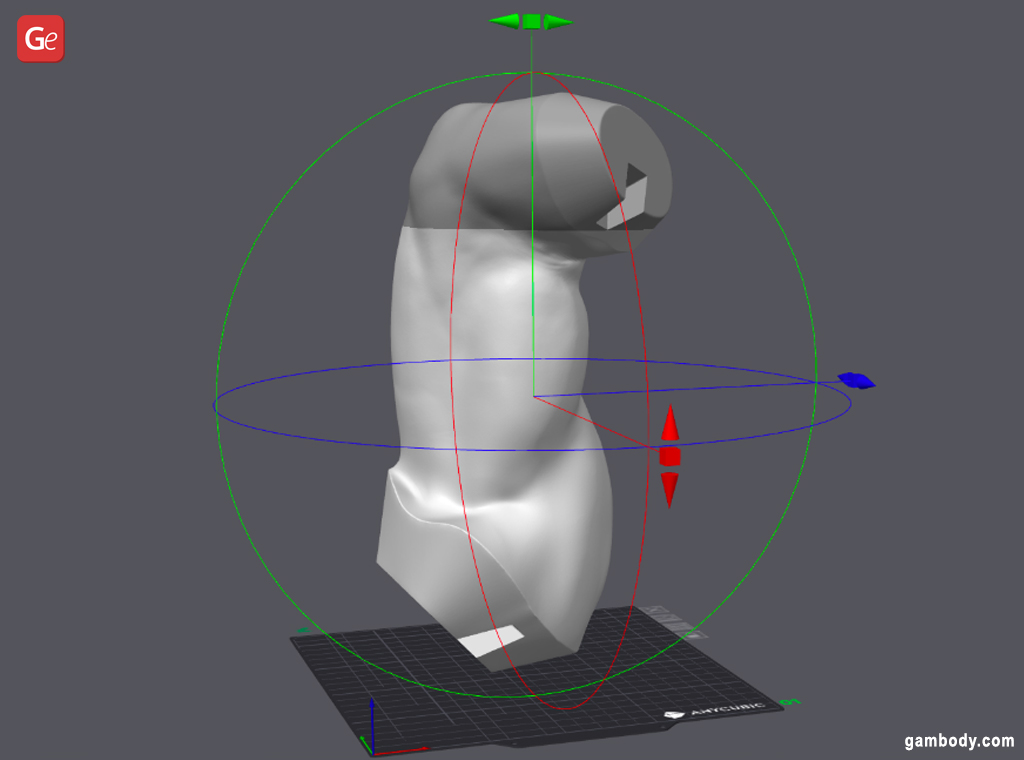

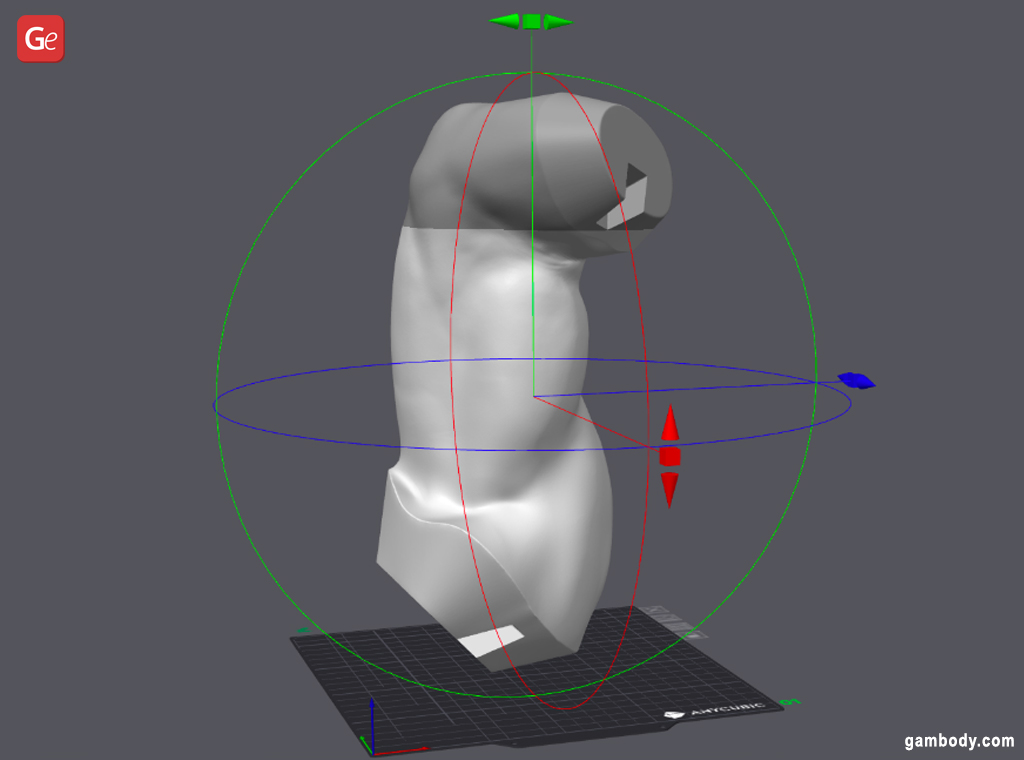

Step 1. Open the STL file in Bambu Studio and upscale it by 800 p.c.

Step 2. Place the mannequin in probably the most compact place.

Step 3. Choose the minimize airplane, contemplating the place for 3D printing and the ultimate look.

Step 4. Add pins (if you need).

Step 5. Repeat the steps above till all of your 3D printing components match the printer mattress. Be certain that the pins you add don’t intrude with one another however enable you with future mannequin meeting.

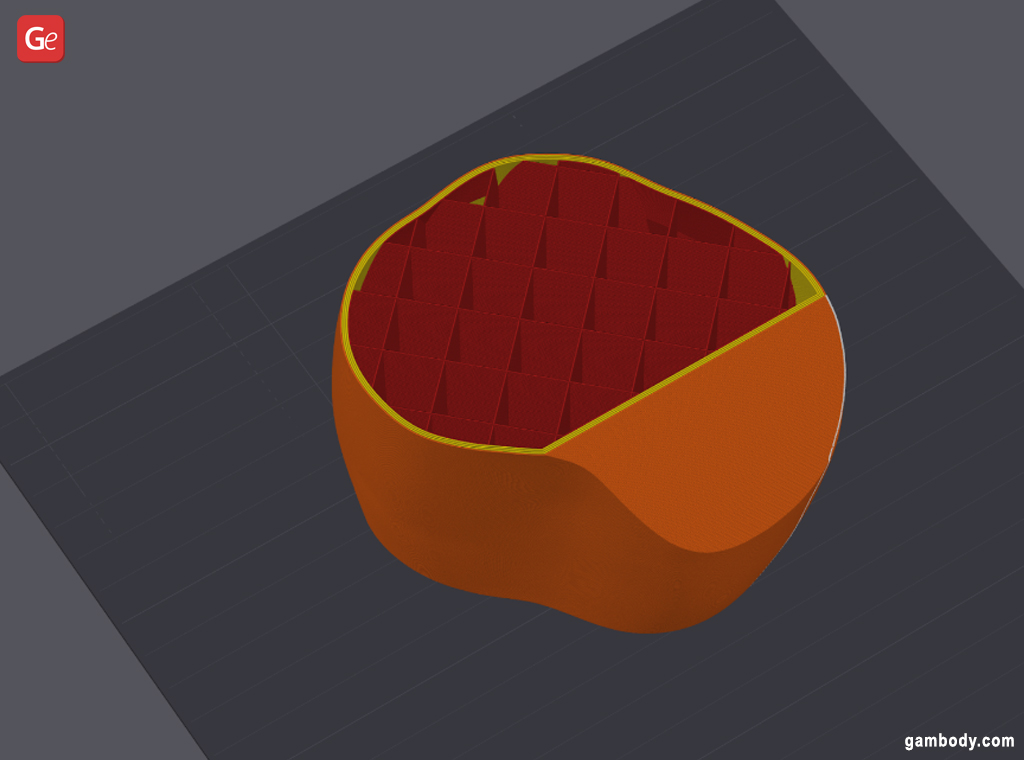

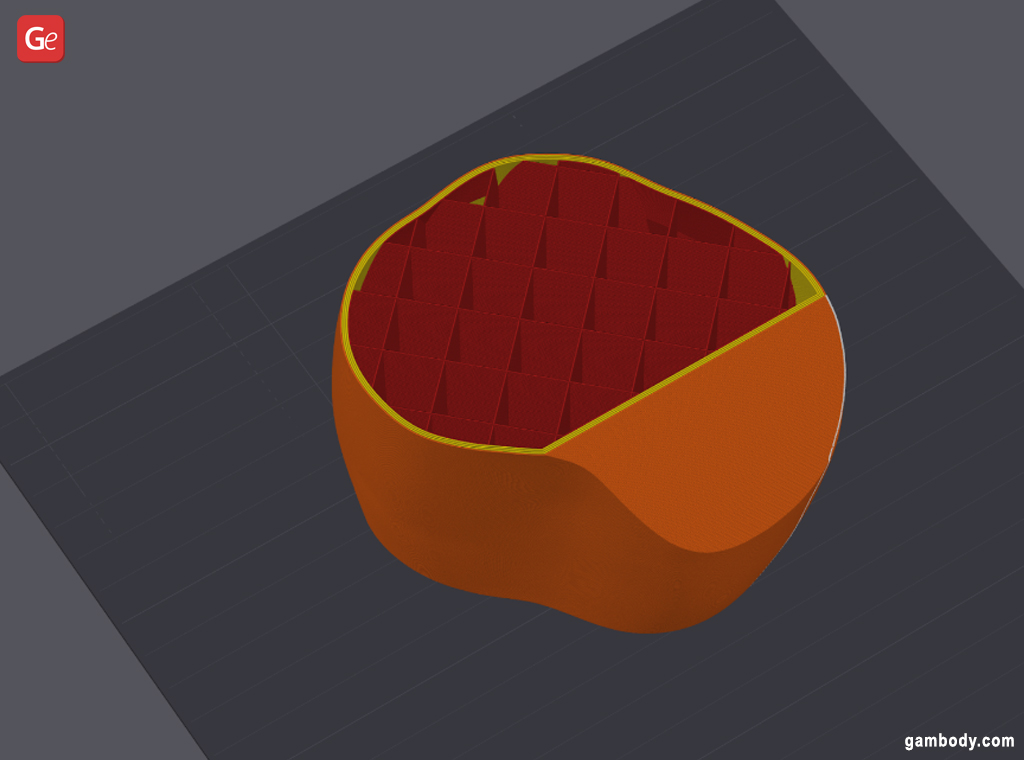

Step 6. Use 4 to five outer partitions and a couple of to three p.c infill to make sure the half energy and minimal use of filament.

Learn additionally: Easy methods to 3D Print Life-Measurement Iron Man Statue: Interview with David Maeseele.

Autodesk Maya 3D

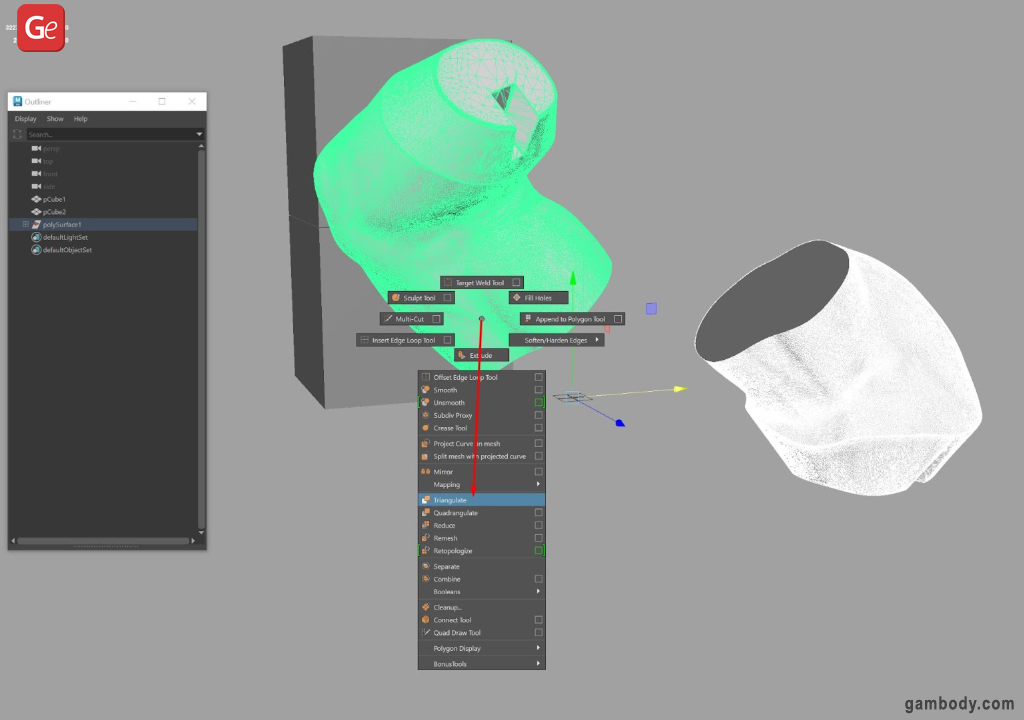

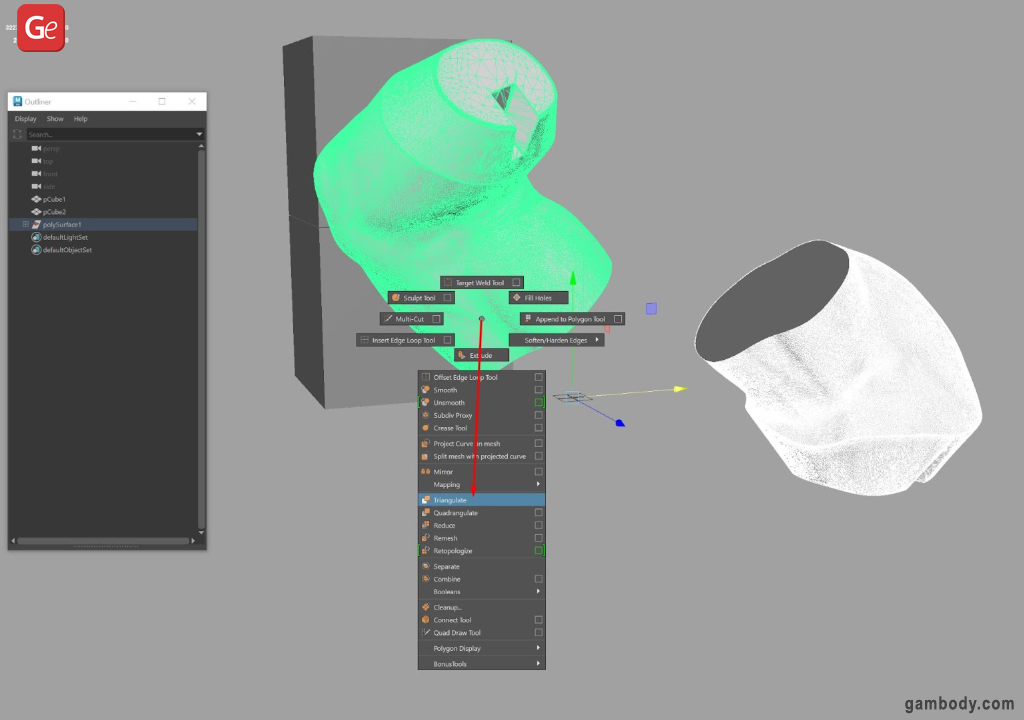

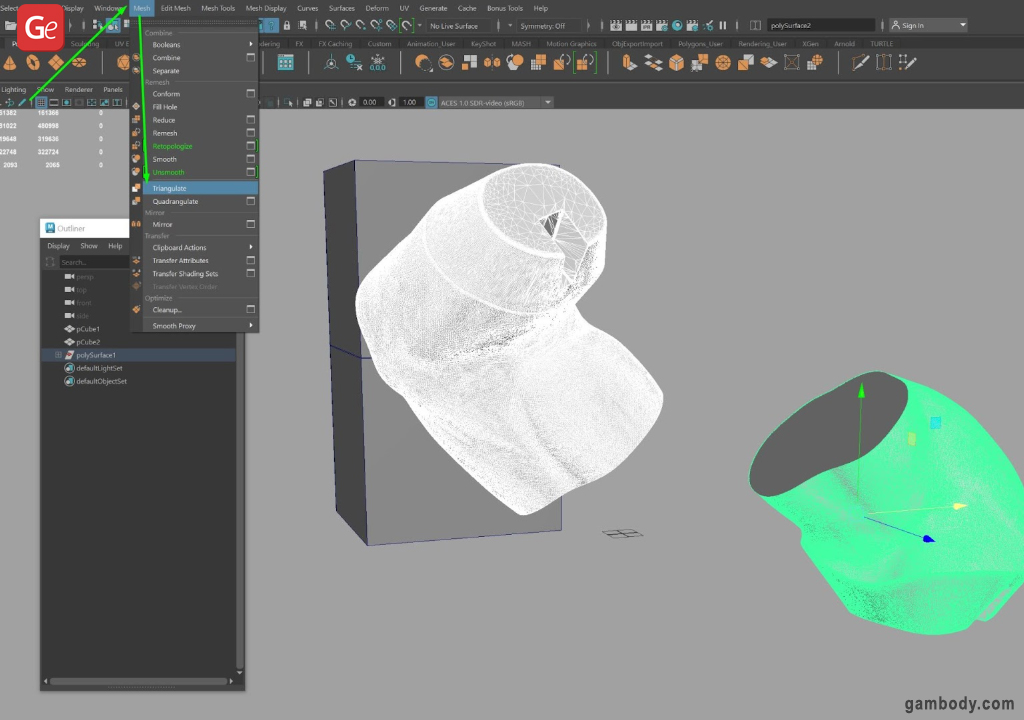

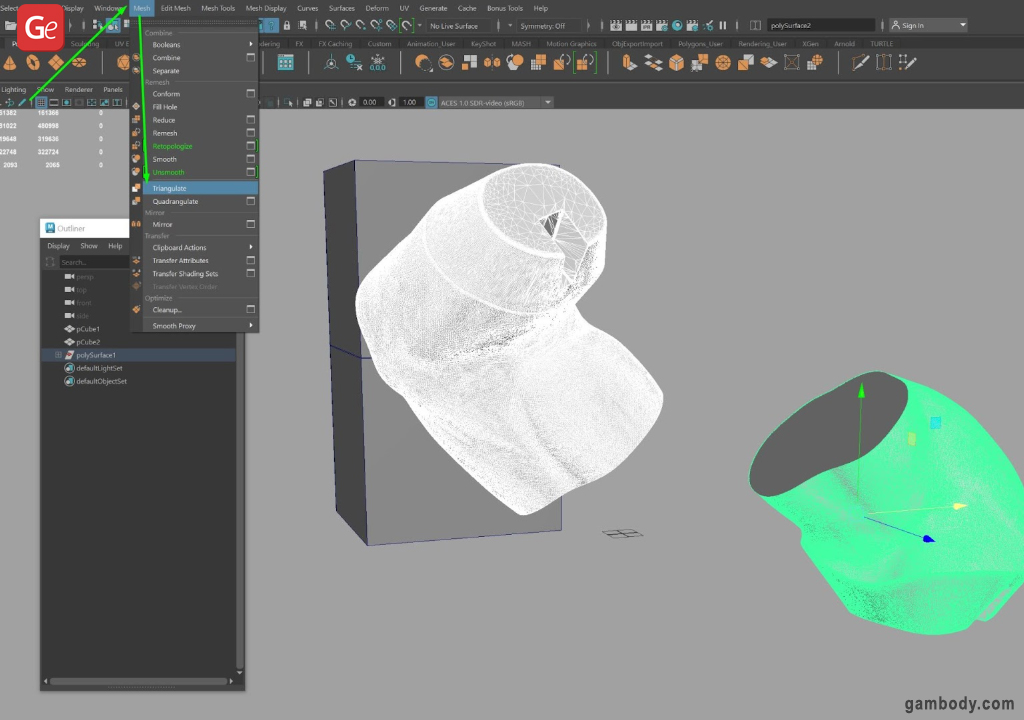

If you end up 3D printing massive components and want to break up STL with Autodesk Maya 3D, put together for extra steps than when utilizing Bambu Studio or Fusion 360.

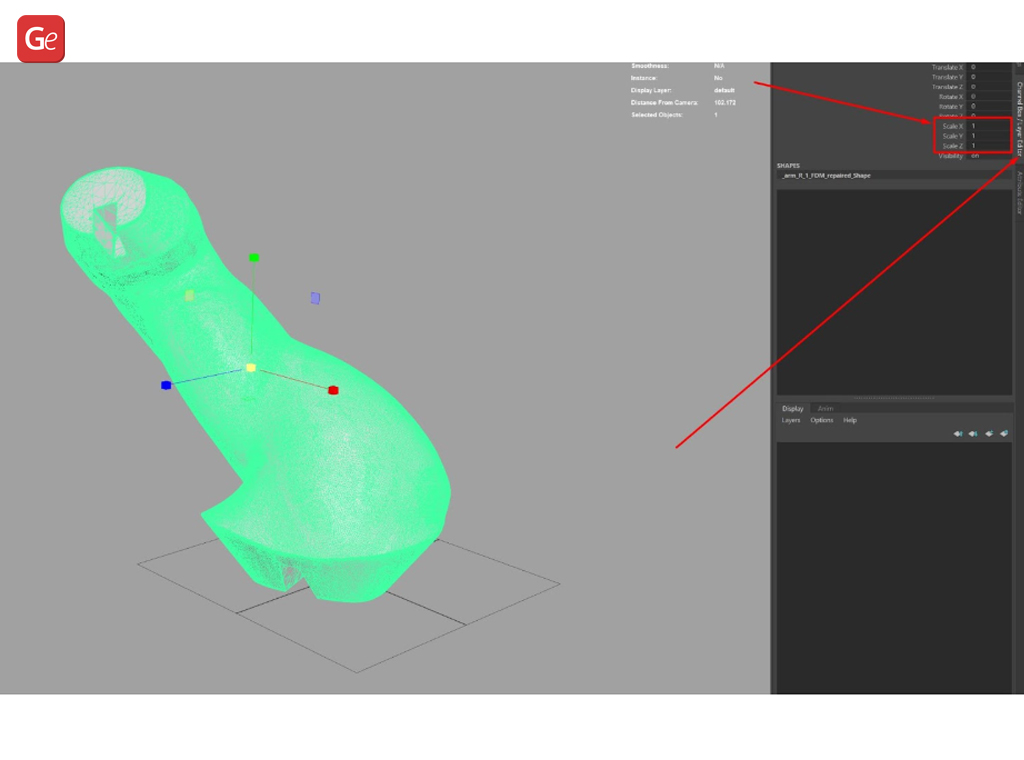

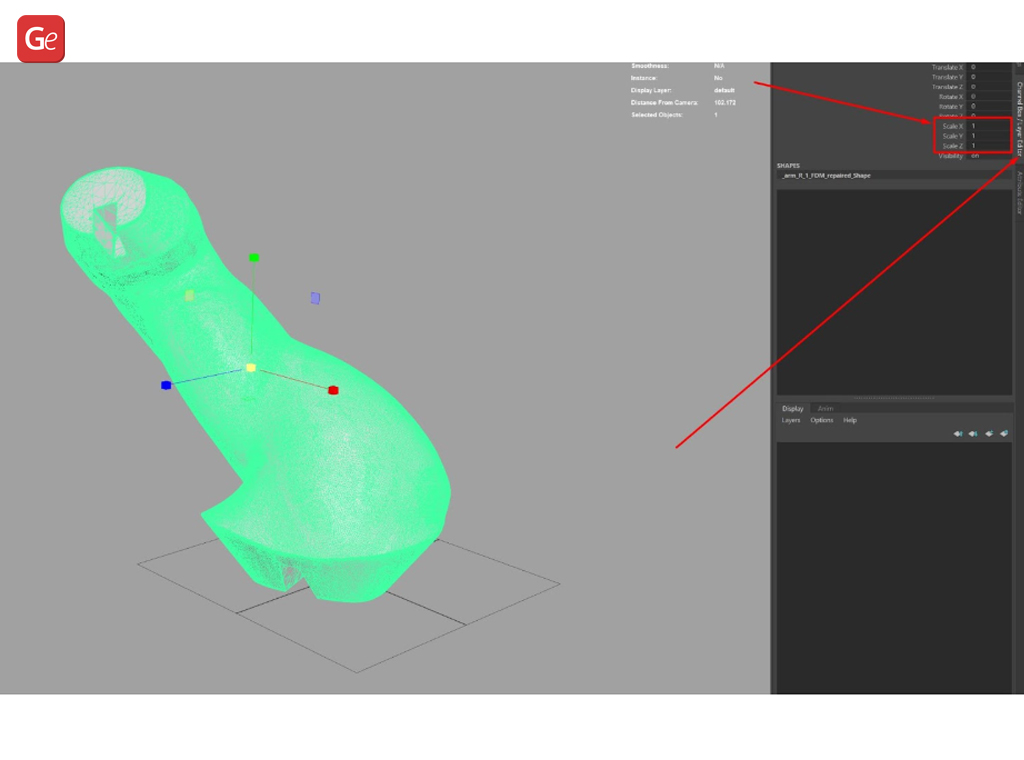

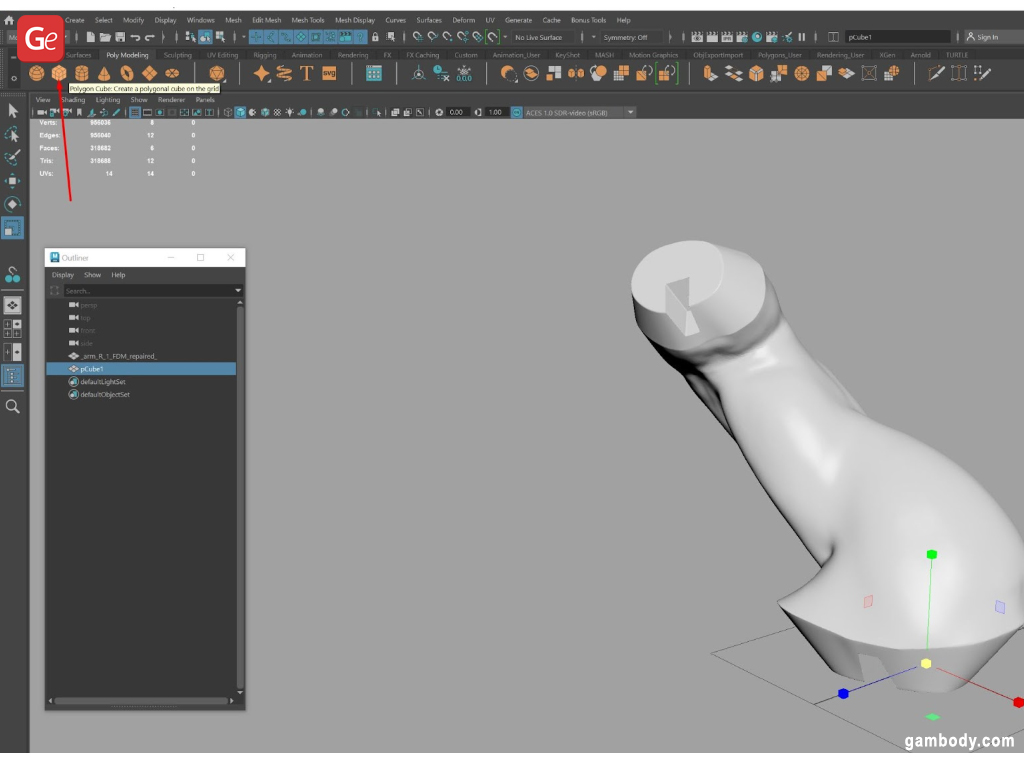

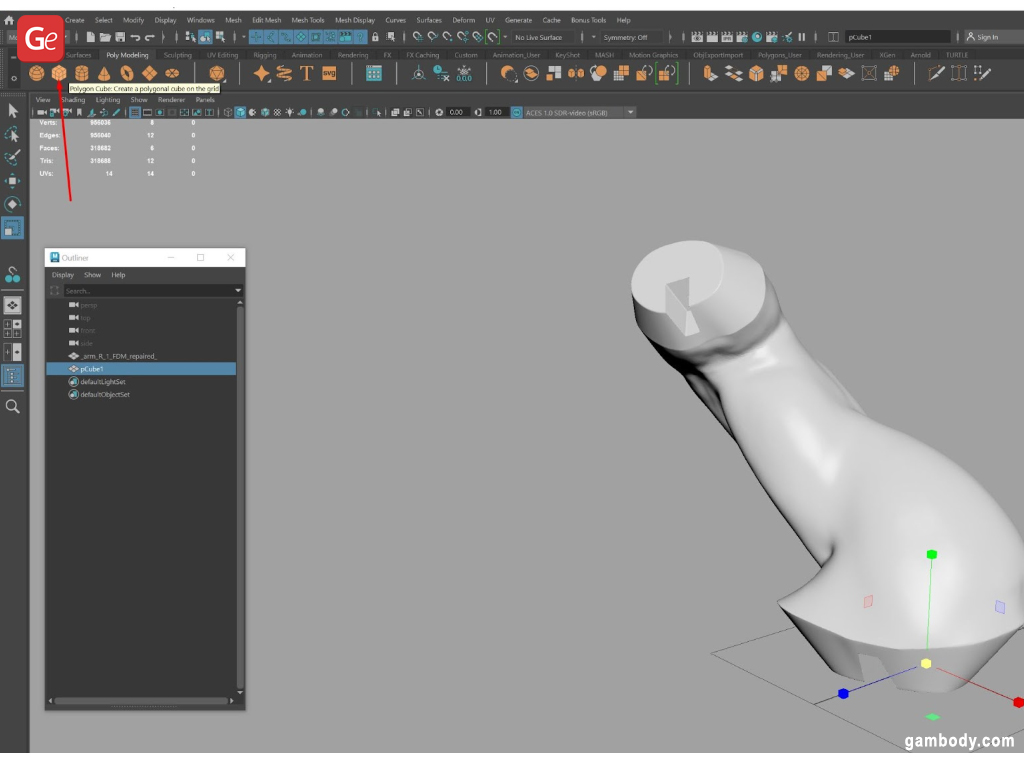

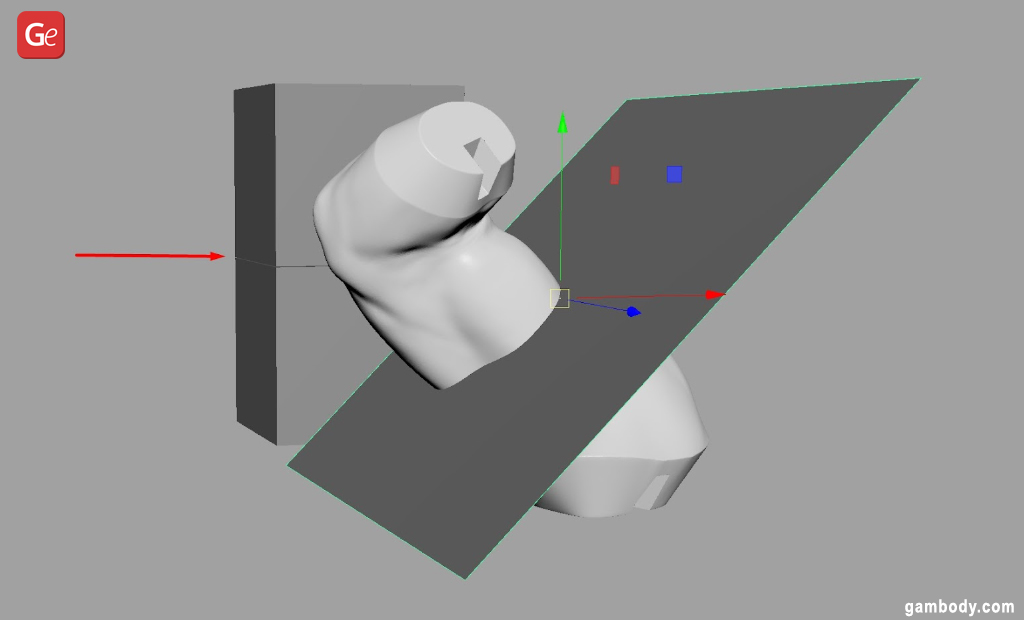

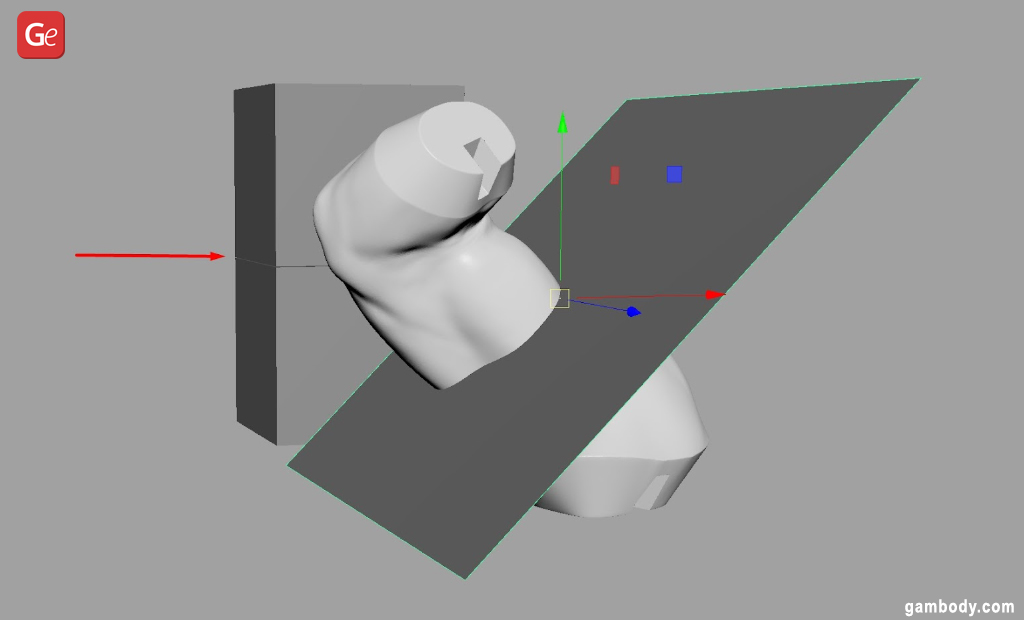

Step 1. Import your venture into Maya 3D and place it.

Step 2. Utilizing “Channel Field,” scale up your mannequin to life-size by altering the “Scale” parameters for X, Y, and Z, the place 1 = 100%.

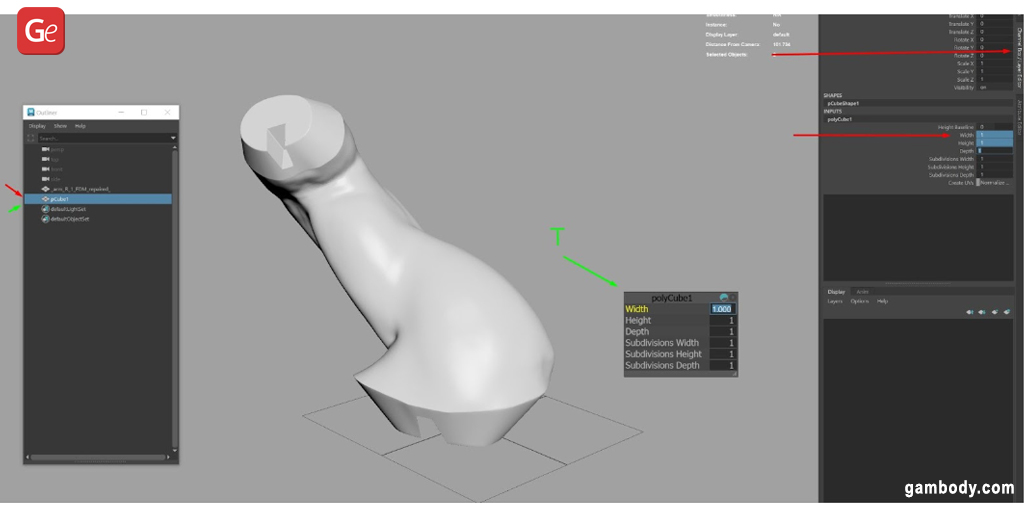

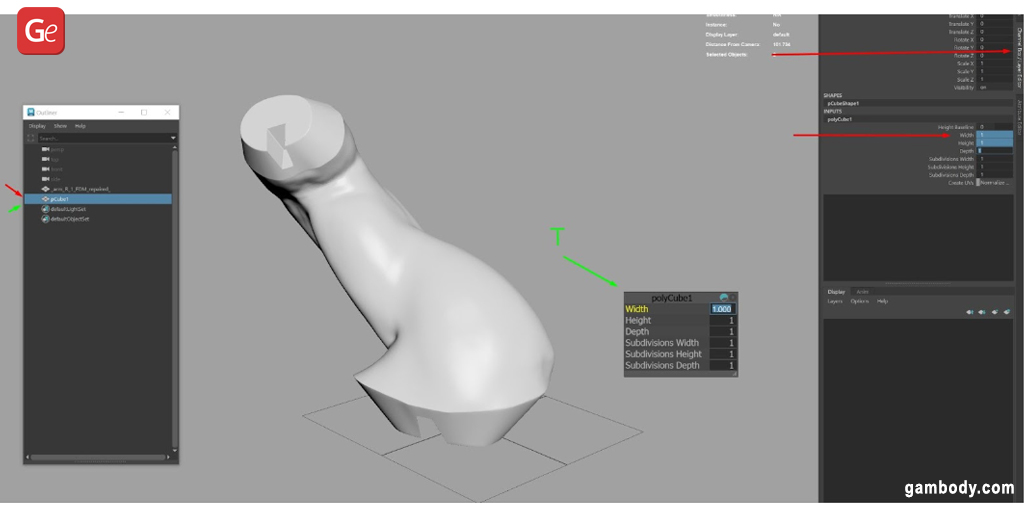

Step 3. Create a dice matching the utmost construct quantity of your 3D printer to keep away from upscaling an even bigger mannequin than you’ll be able to probably print.

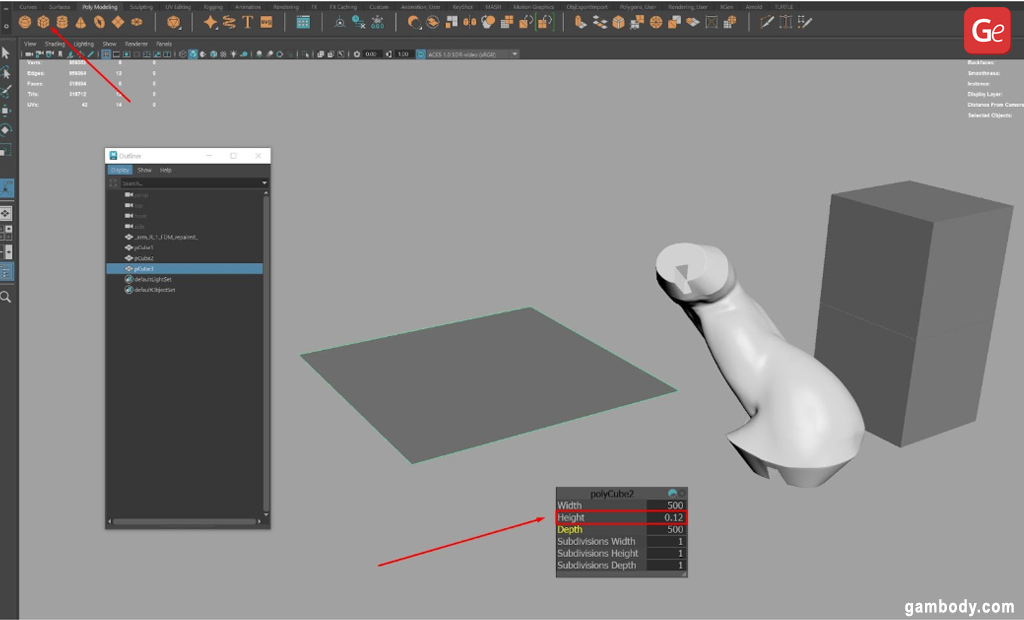

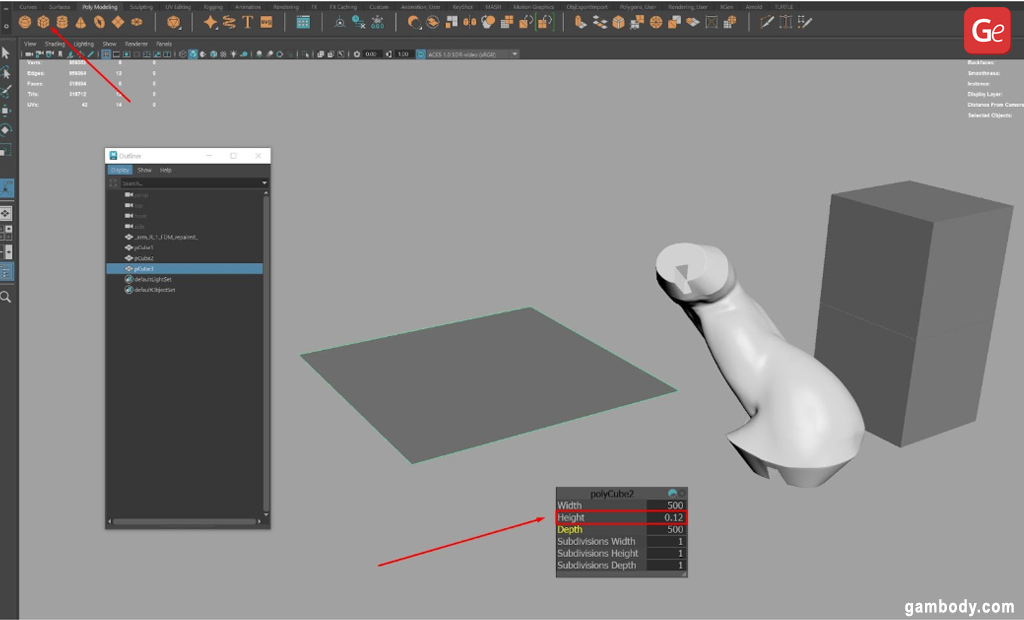

Use the “Channel Field” and a “T” key to create a polyCube with a peak of 0.12 mm. Different parameters don’t matter as a lot.

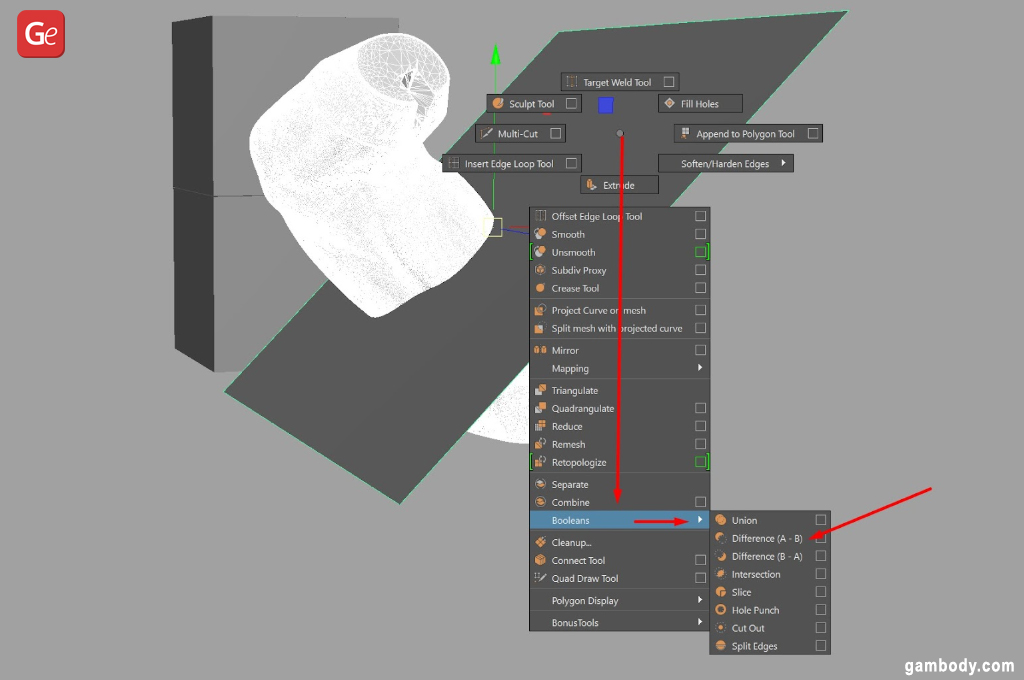

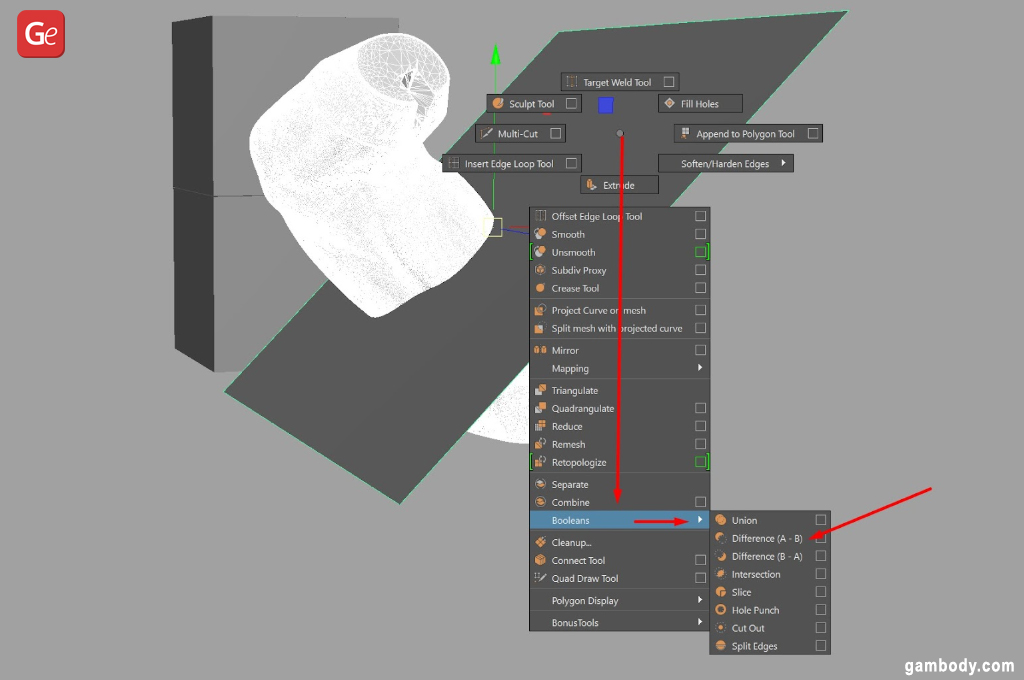

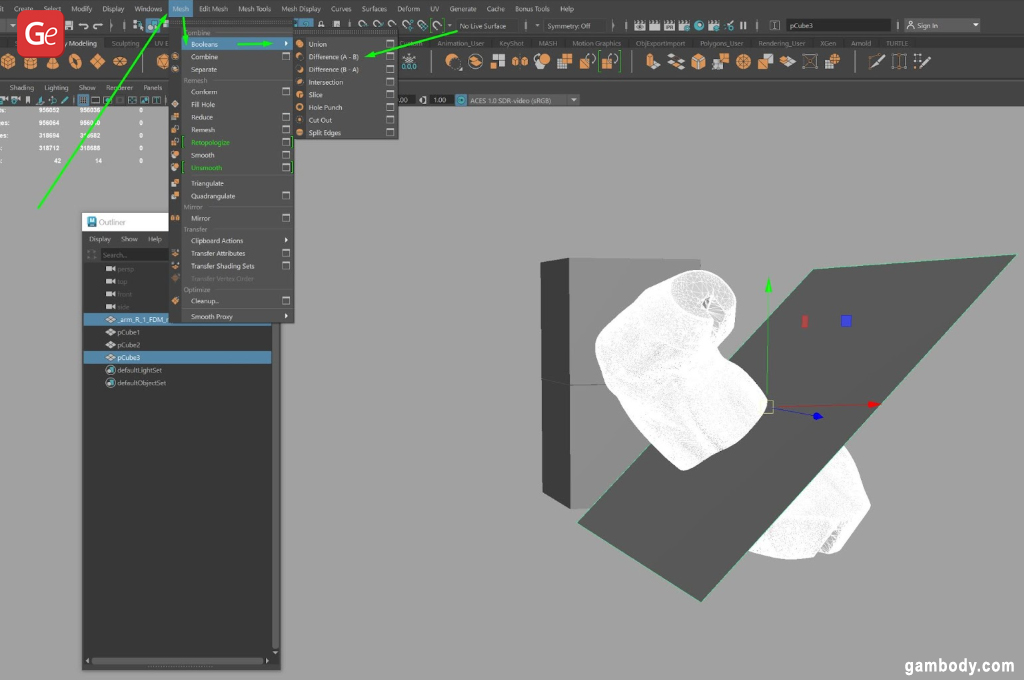

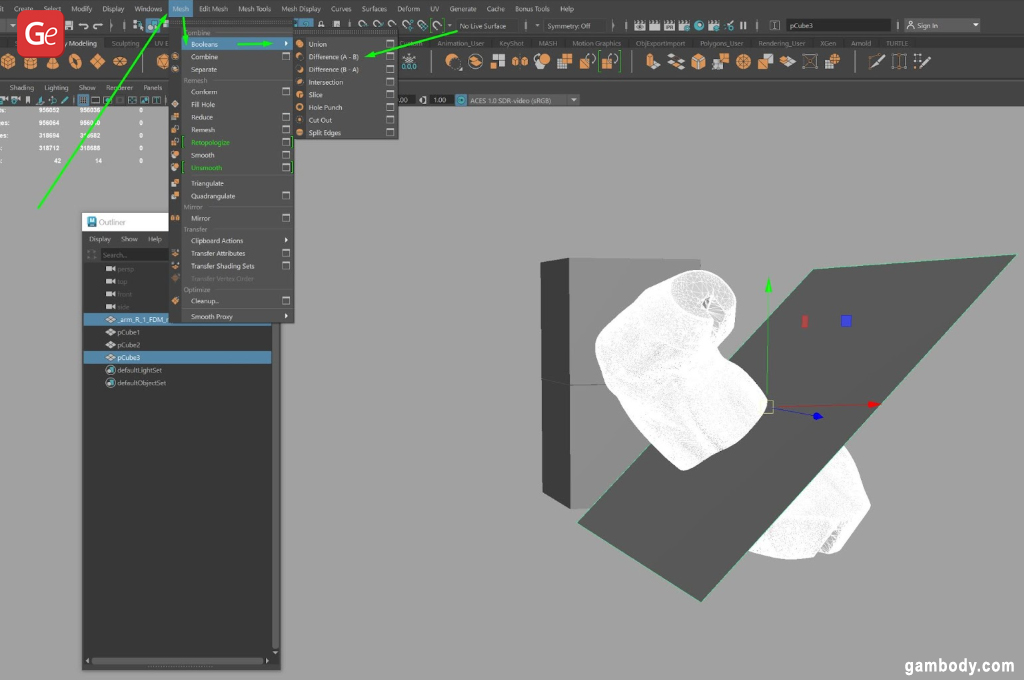

Step 4. Place the blade the place you want to break up STL. Maintain “Shift” whereas choosing the 3D printing half you want to break up after which the dice and select “Booleans” for slicing.

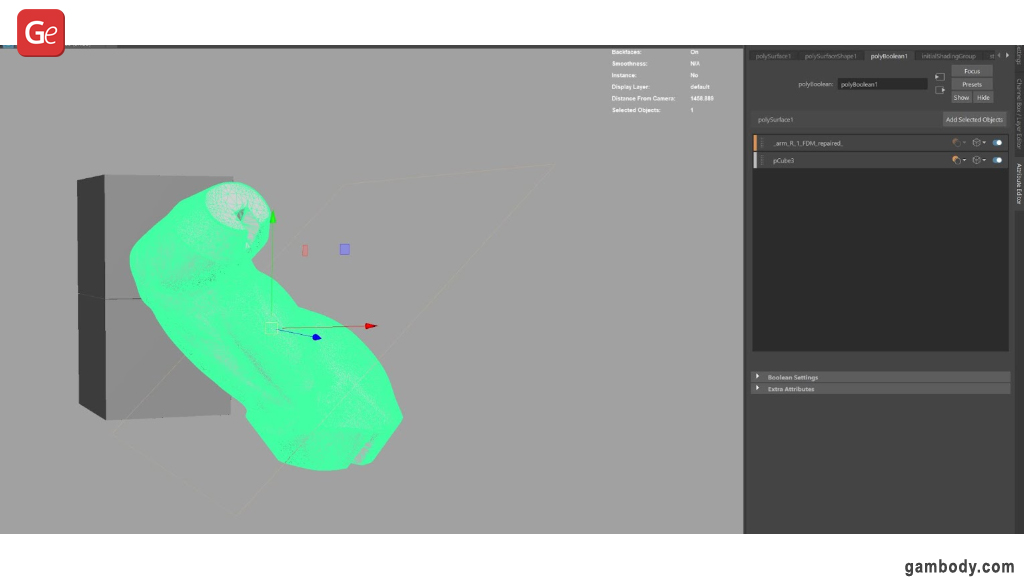

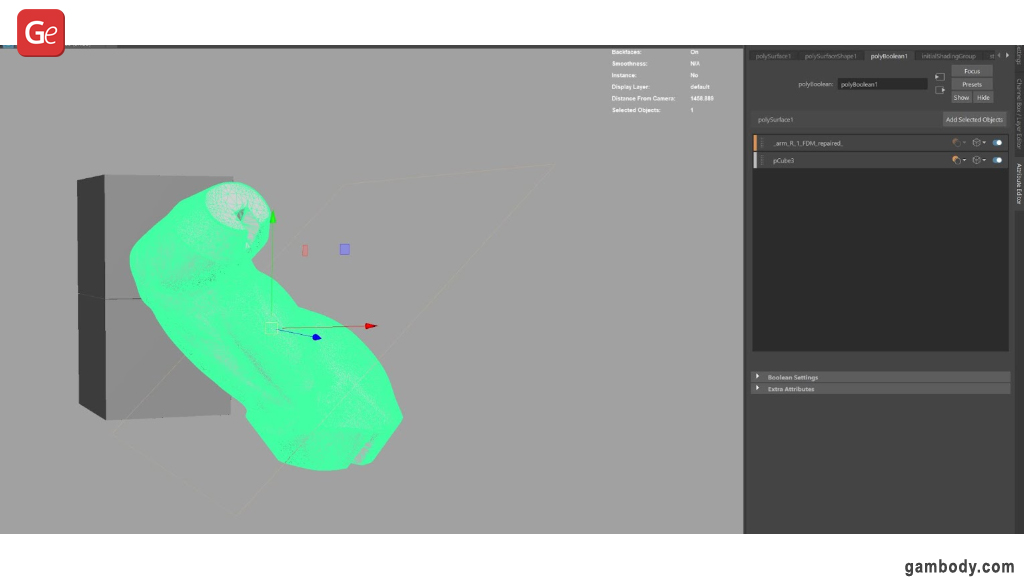

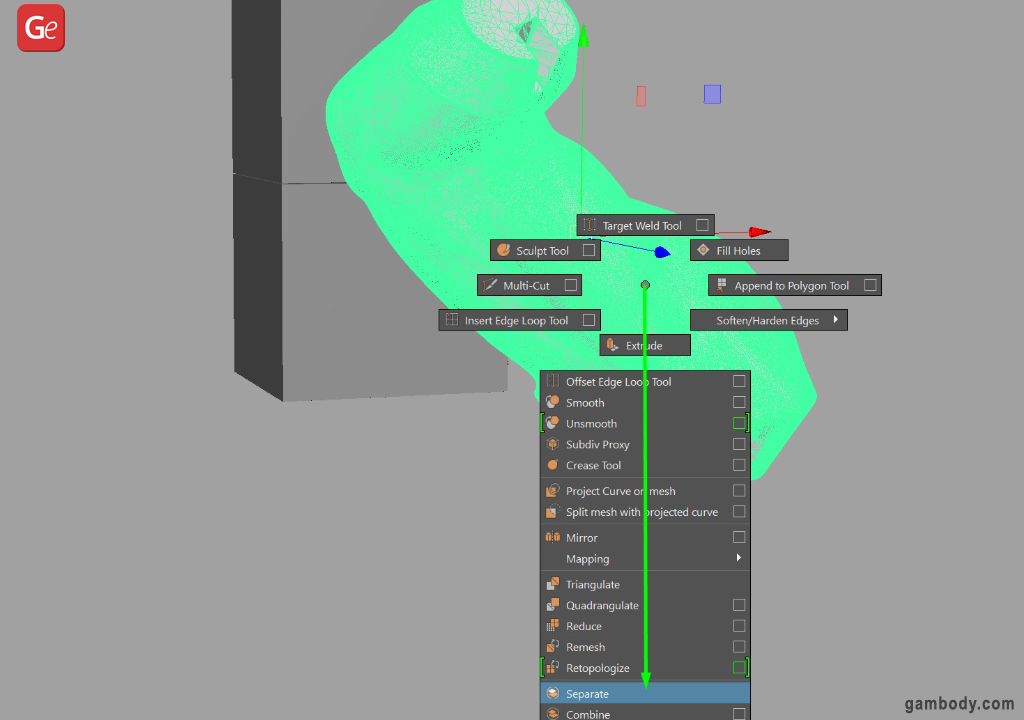

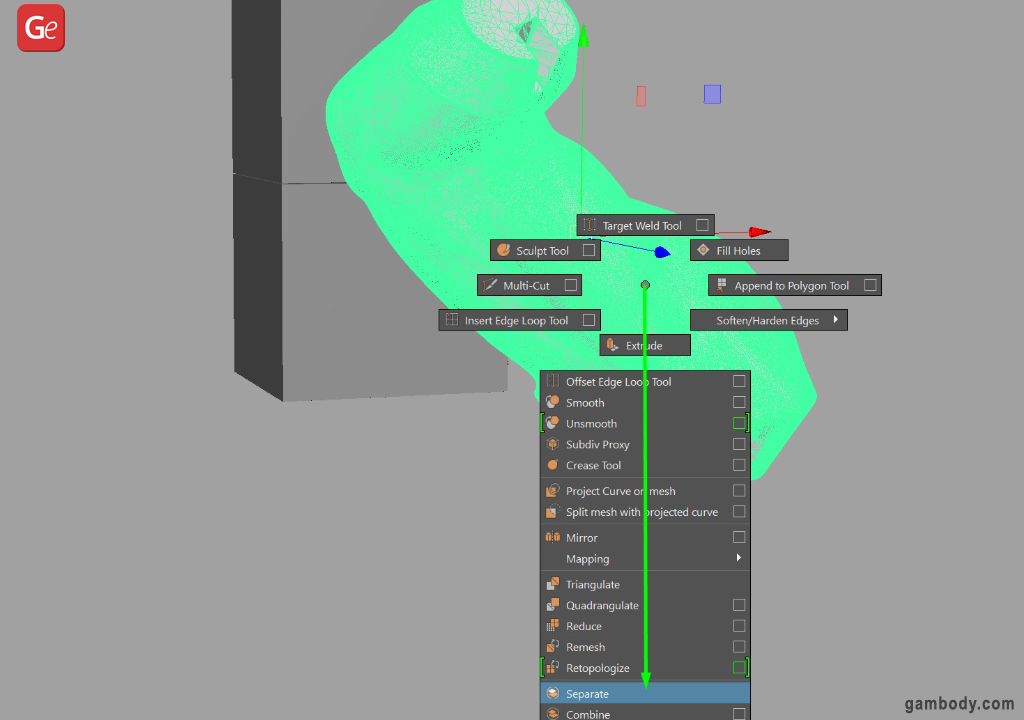

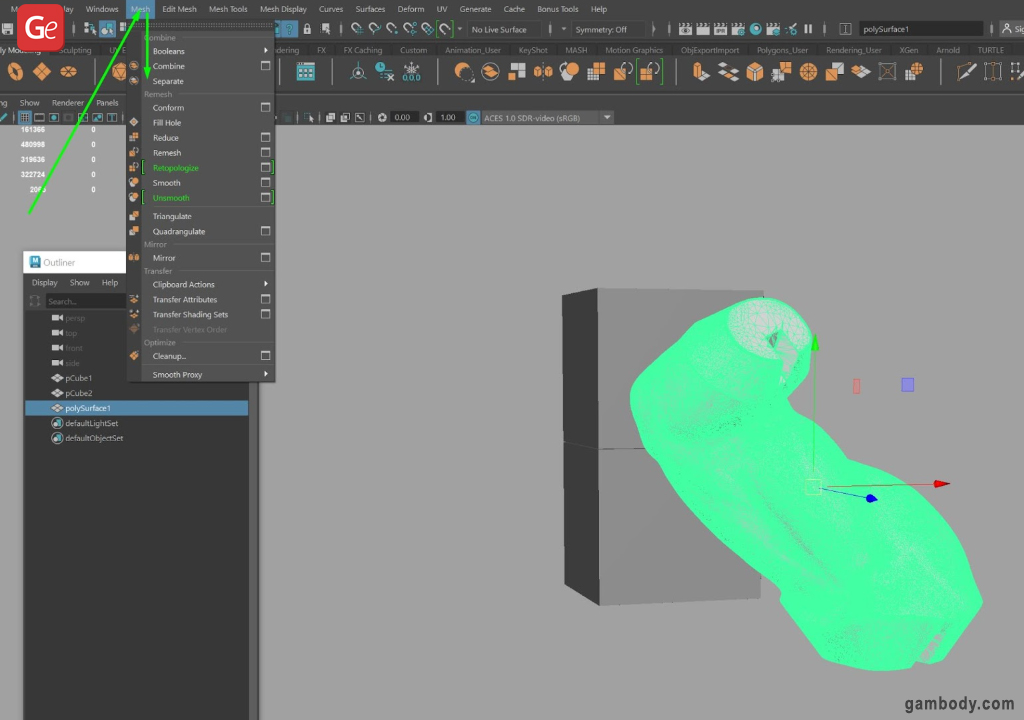

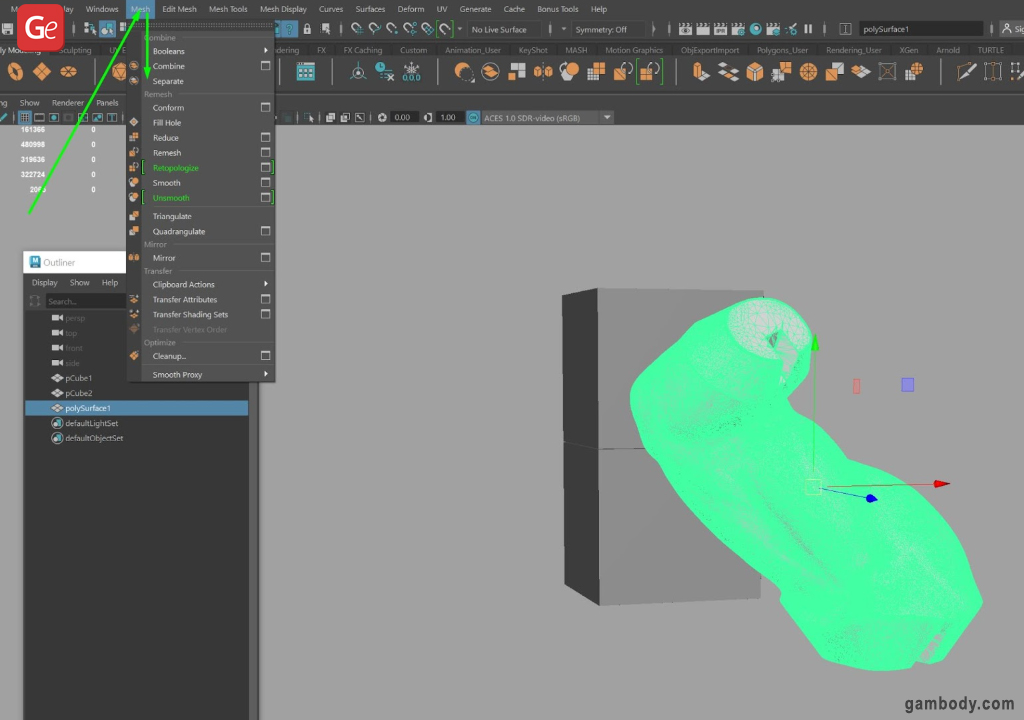

- Technique 1. Press and maintain “Shift” and RMD and select the “Distinction (A-B)” in “Booleans” or choose the components and go to “Mesh” – “Boolenas” – “Distinction (A-B). Keep in mind to make use of the Shift+Alt+D mixture to clear the cache, and your object remains to be thought of as “strong” despite the fact that with a minimize. Use the “Separate” choice to separate it.

- Technique 2. Choose the 3D printing half you want to break up and press-hold Shift+RMD whereas selecting “Mesh” – “Separate.”

- Choose all of the components and use the “Mesh” – “Triangulate” choice (by holding Shift+ RMB or by the Mesh menu) to export them accurately.

Now you’ll be able to work in your enormous 3D prints!

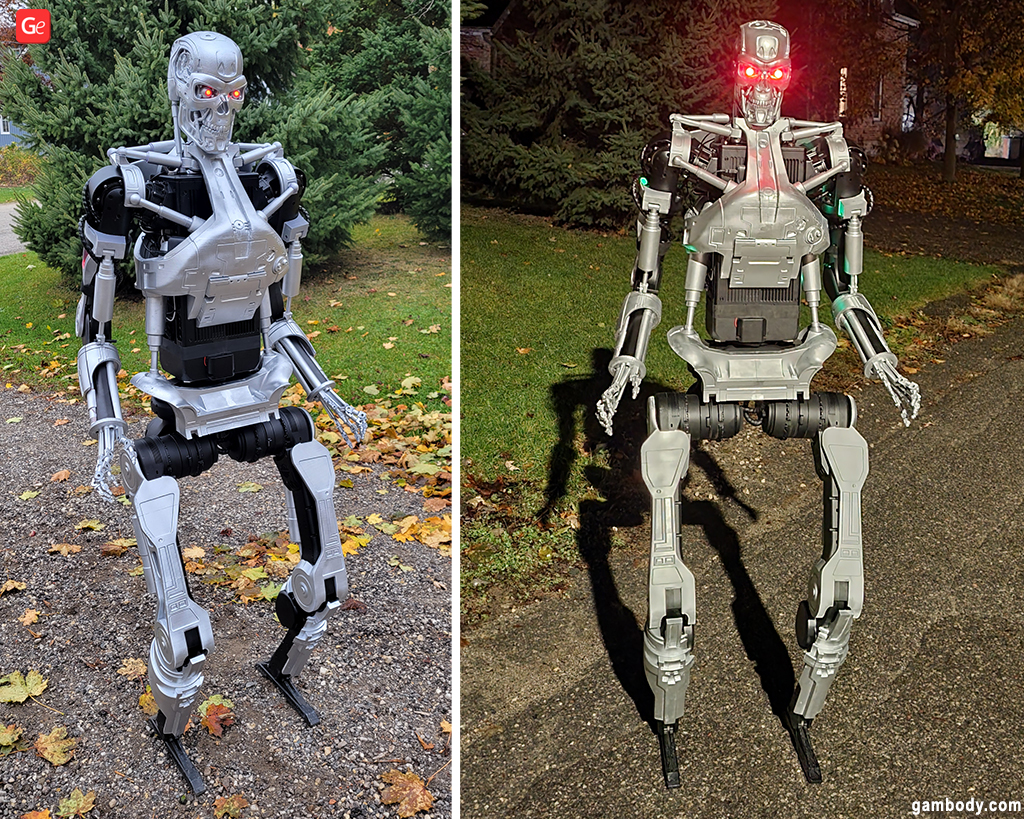

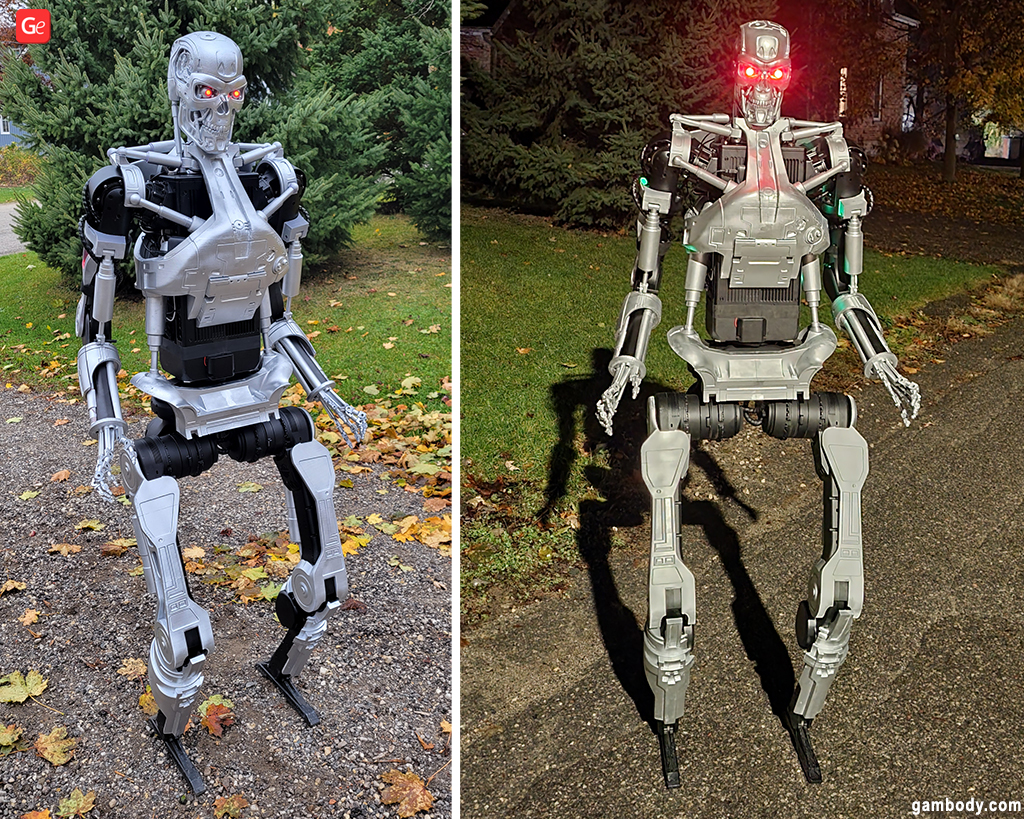

Learn additionally: Strolling Terminator Endoskeleton (How a Humanoid Robotic Grew to become a Nightmare Animatronic).

Blender

This open-source software program for 3D modeling may be very widespread. It helps designers sculpt figures and work on advanced fashions, though studying and bettering your expertise takes time. Its foremost benefit is that it’s free, and you could find loads of tutorials on-line to help you with printing massive objects and enable you break up STL information in accordance with your wants.

Blender is likely one of the most difficult STL splitter strategies however provides varied helpful instruments to finish this job. Bender choices for learn how to break up massive 3D prints embrace including angles (vertical or horizontal) or planes that may be angled nevertheless you want.

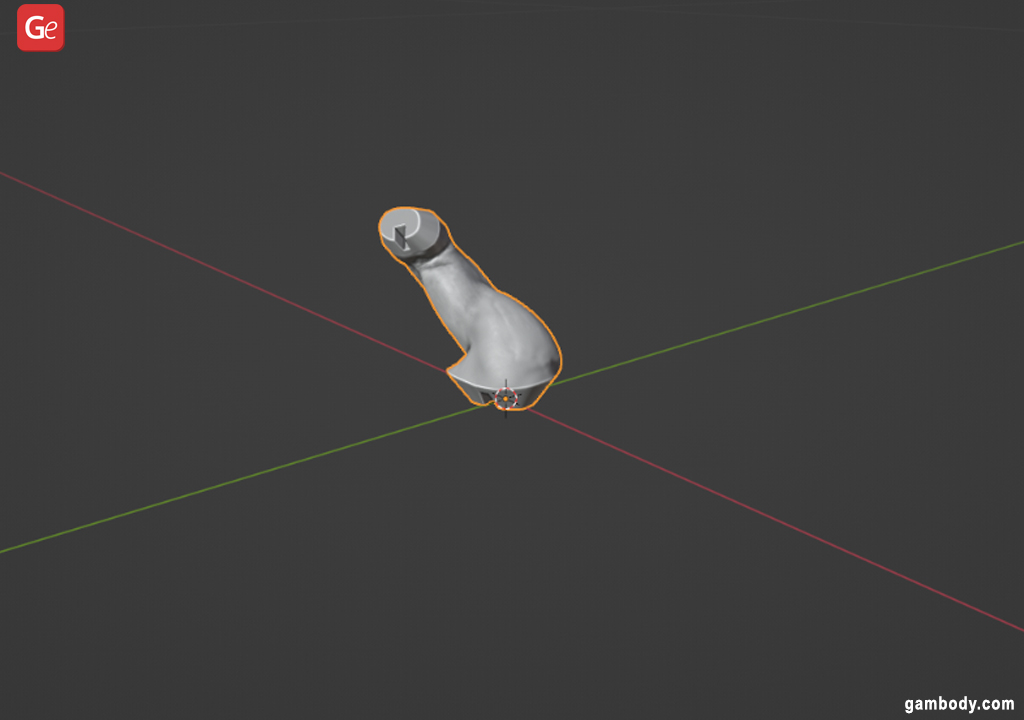

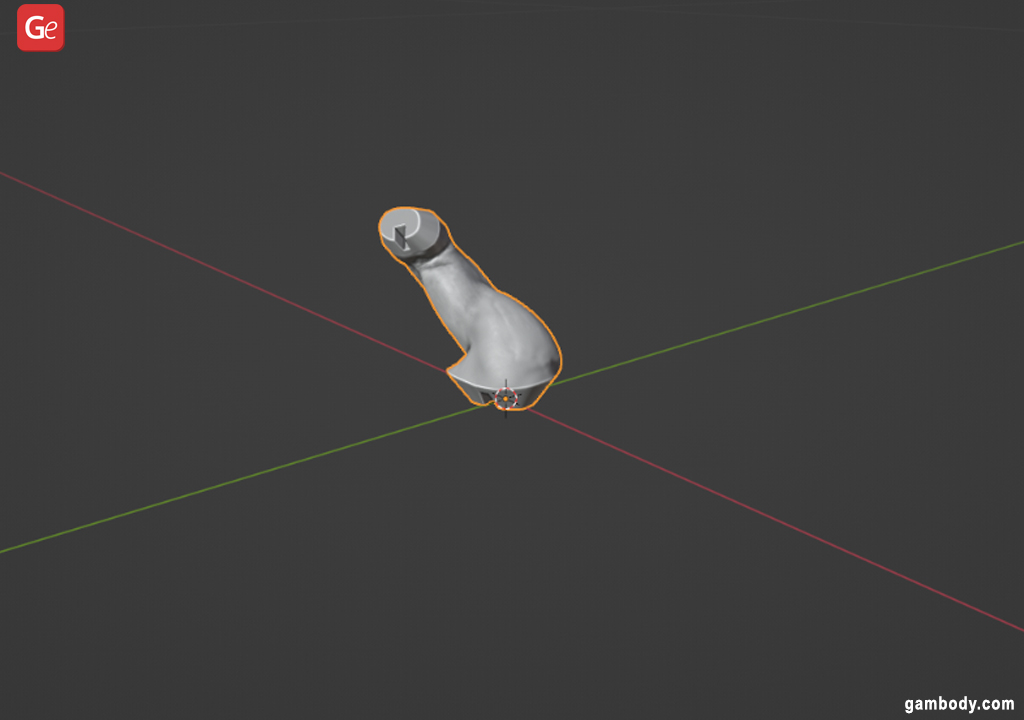

When making massive 3D prints by upscaling a mannequin akin to Cloud Strife, observe this fast information to splitting STL information.

Step 1. Import the file and place your object.

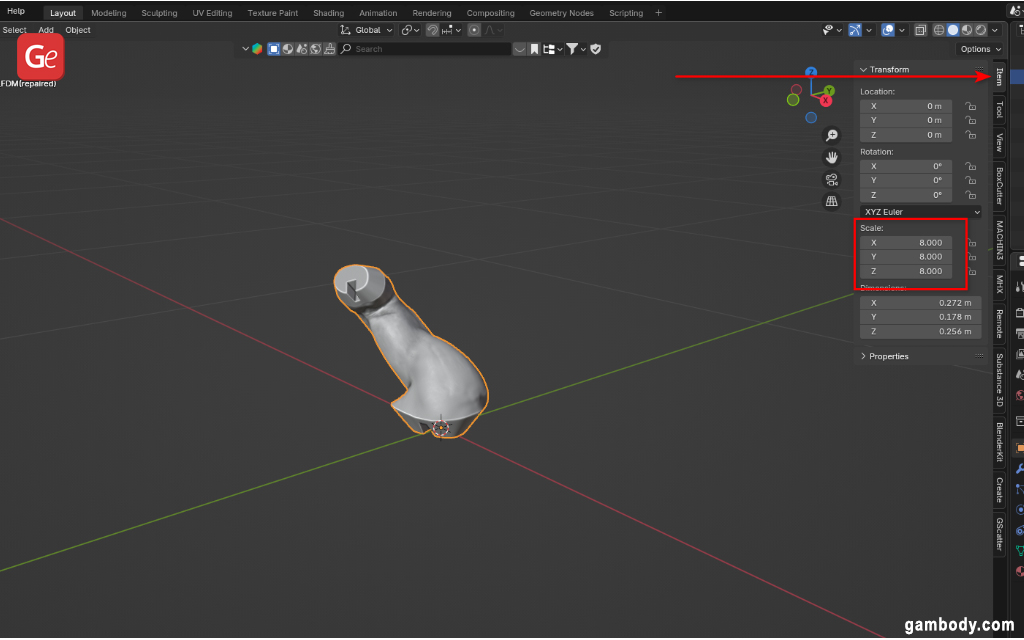

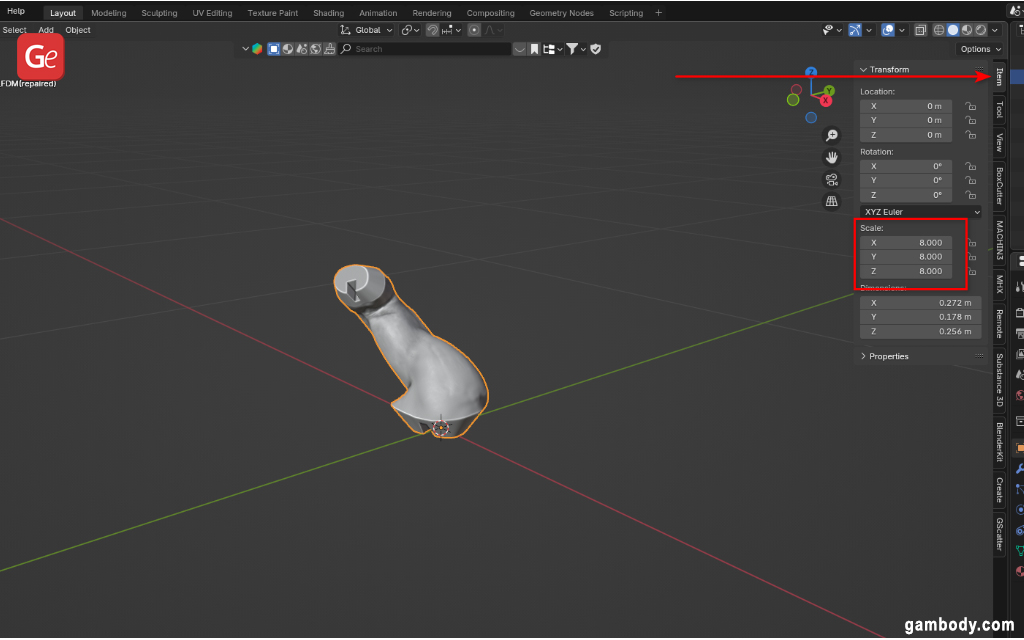

Step 2. Use the “actual Measurement” to upscale the mannequin by 800 p.c. You are able to do this by clicking the “S” (Scale) key and coming into the quantity 8 or by clicking the “N” to entry the menu and coming into “8.000” for “Scale” within the “Merchandise.”

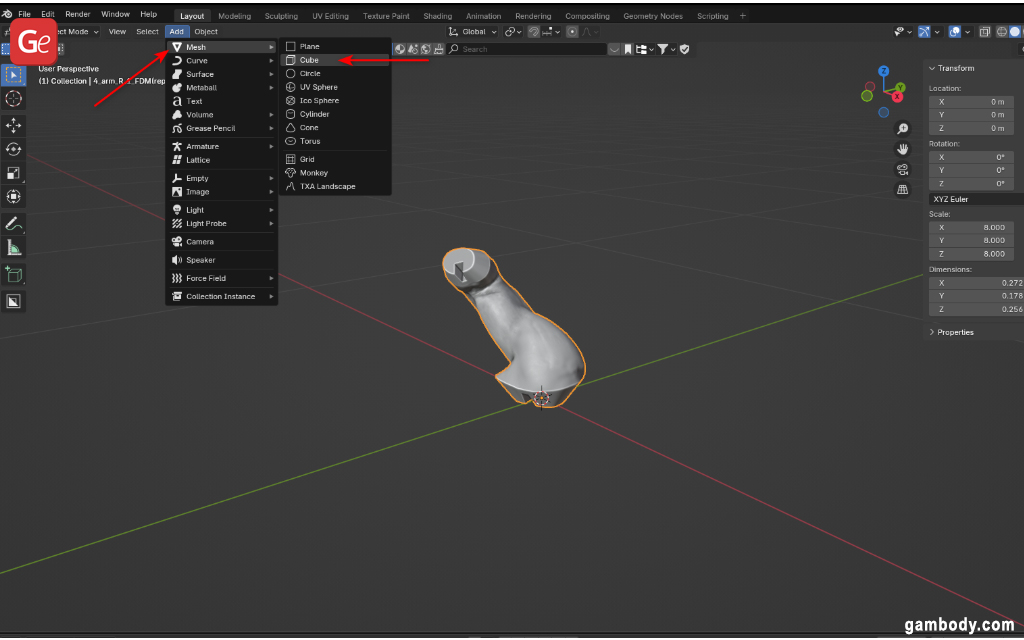

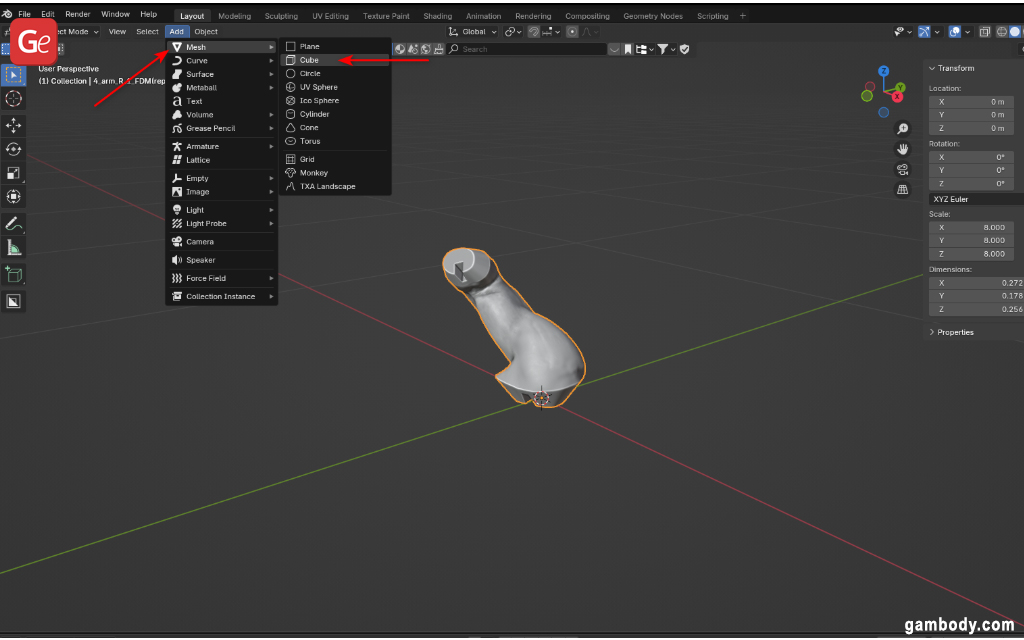

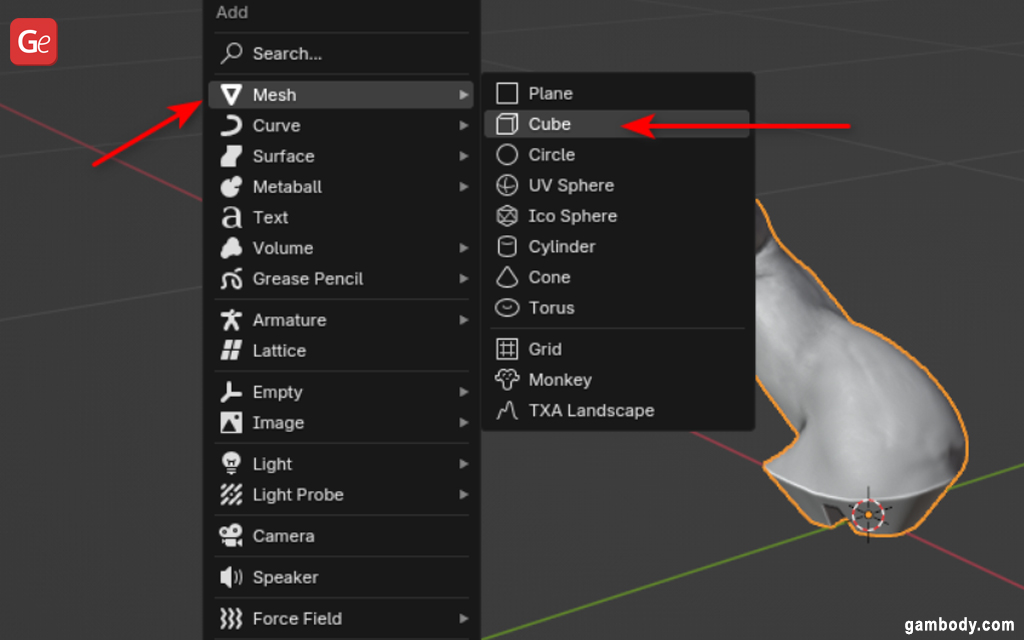

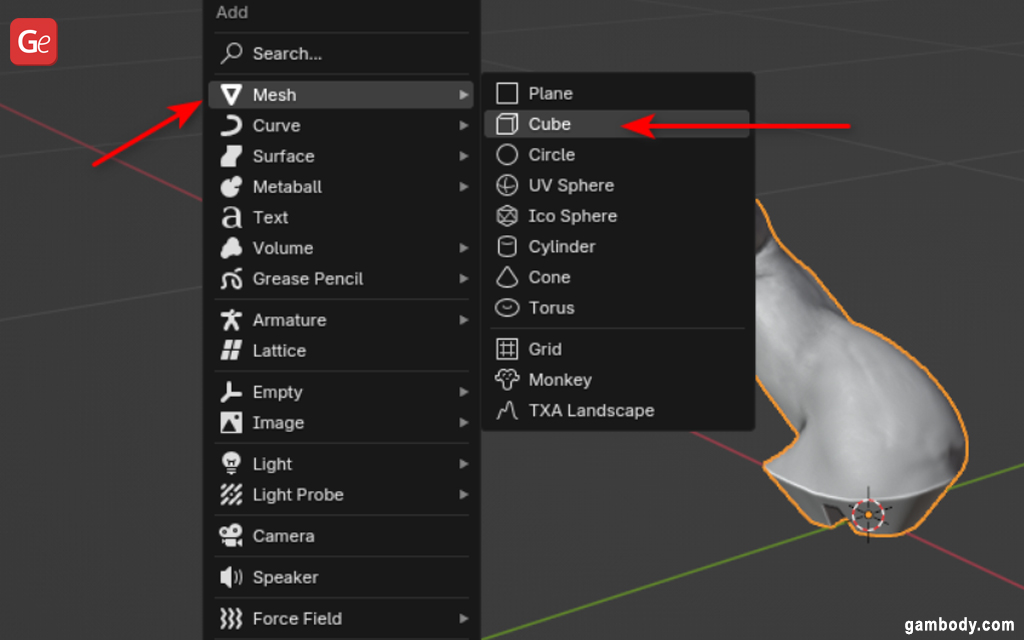

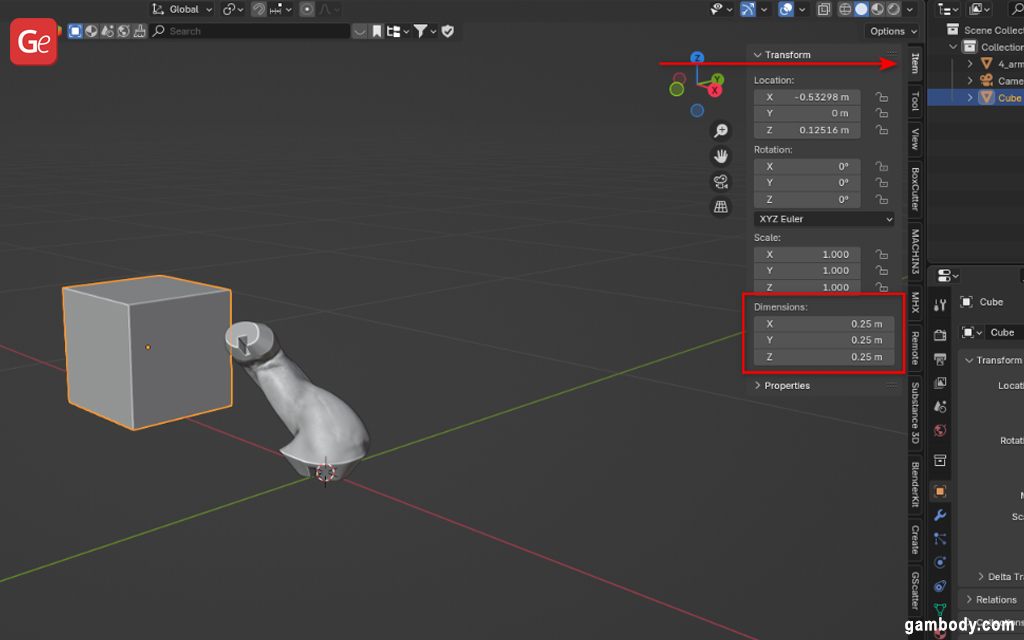

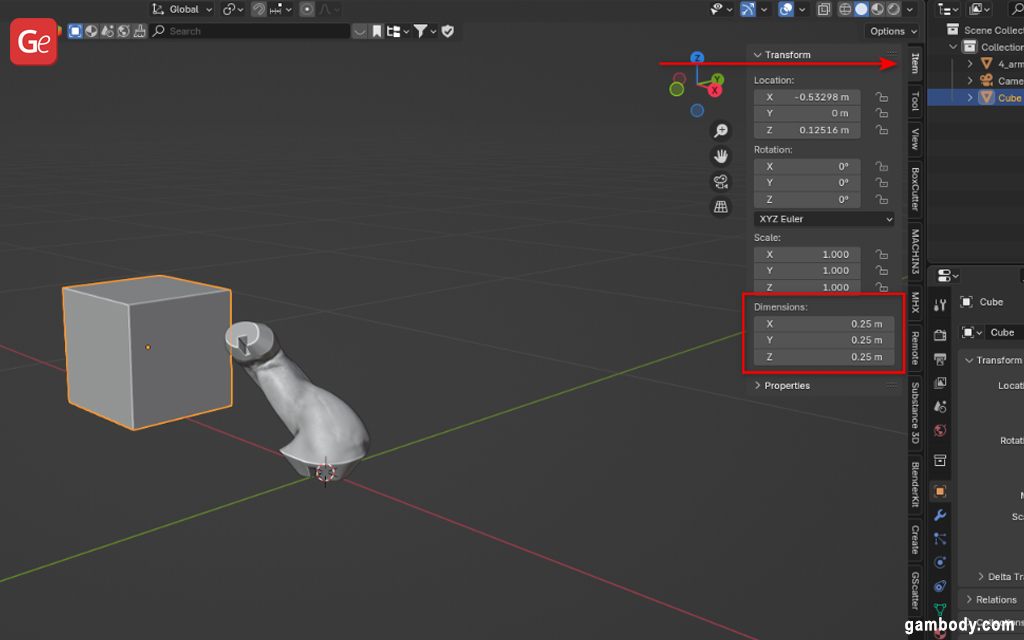

Step 3. Create a dice that’s just like your mattress measurement. You possibly can go to “Add” – “Mesh” and press “Dice” or use Shift+A mix and select “Mesh” – “Dice.”

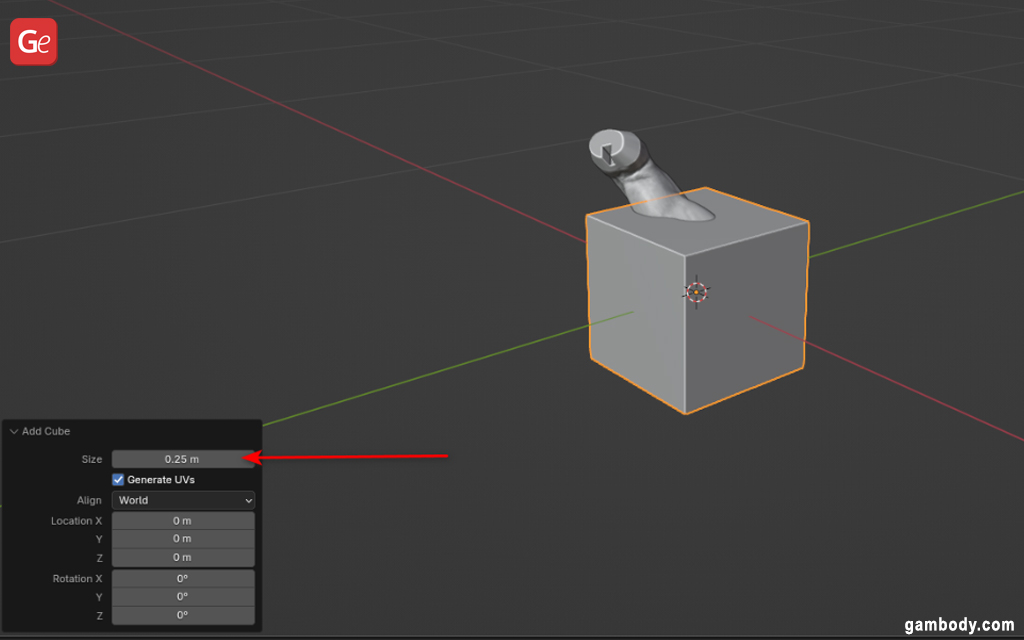

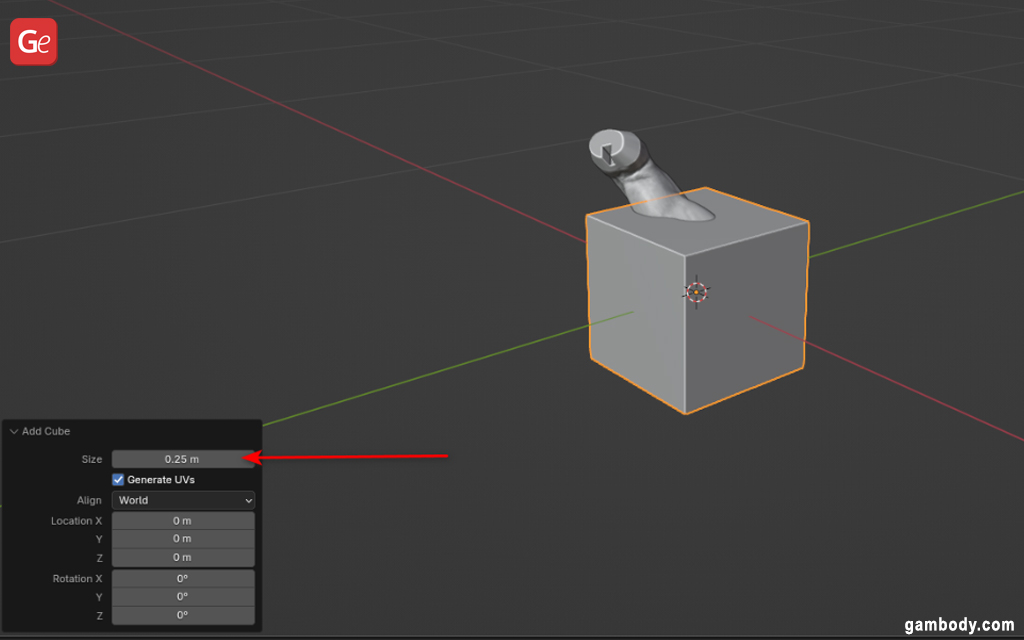

Now you’ll be able to enter the “Measurement” parameters on your Dice or change the “Dimension” in “Merchandise.”

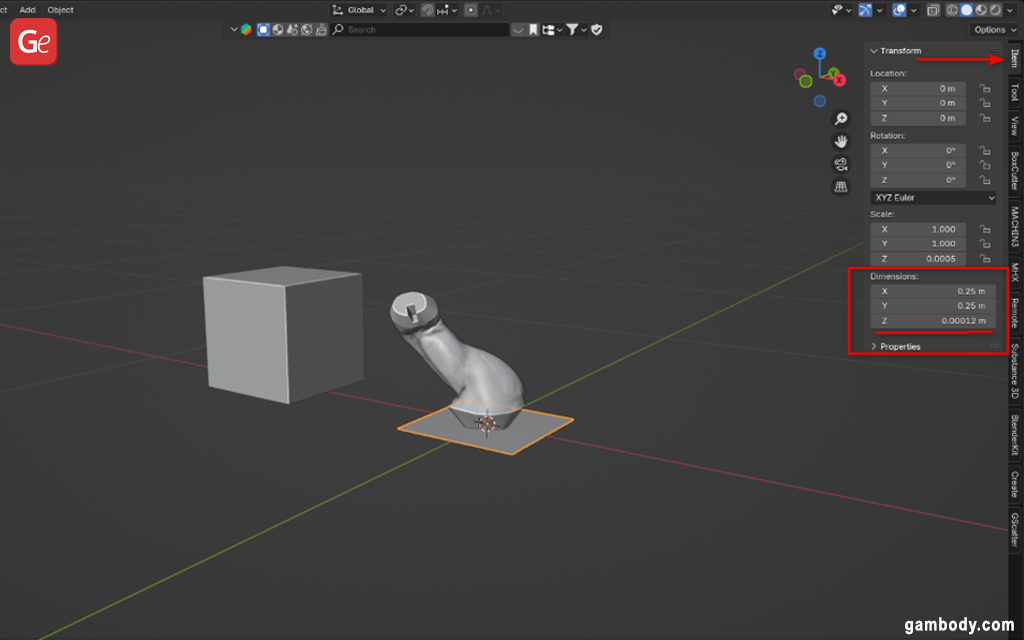

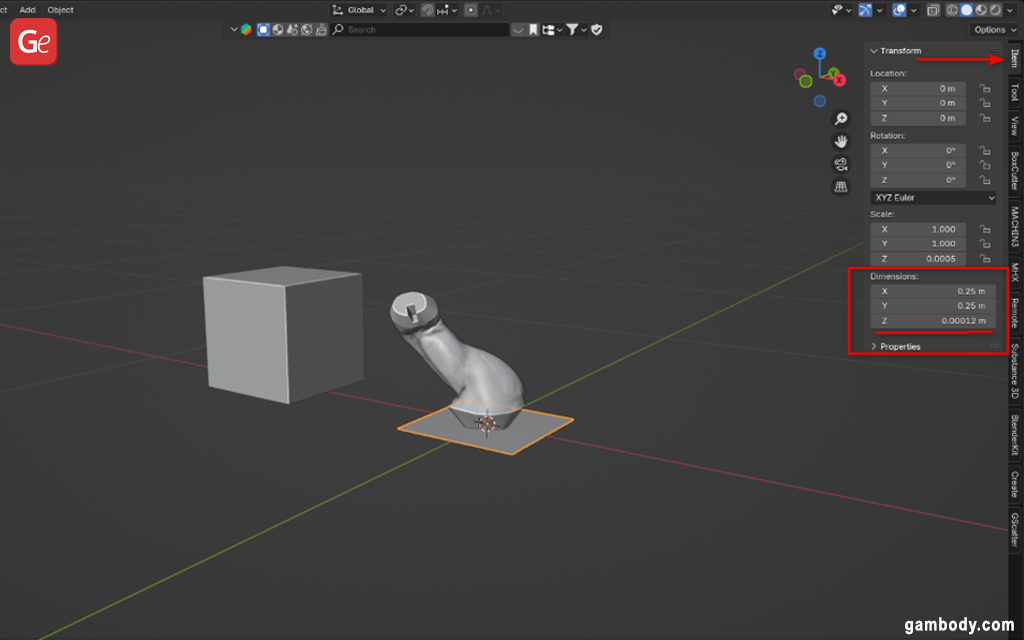

Step 4. Create the blade. Use the Dice Z dimension as 0.00012 m.

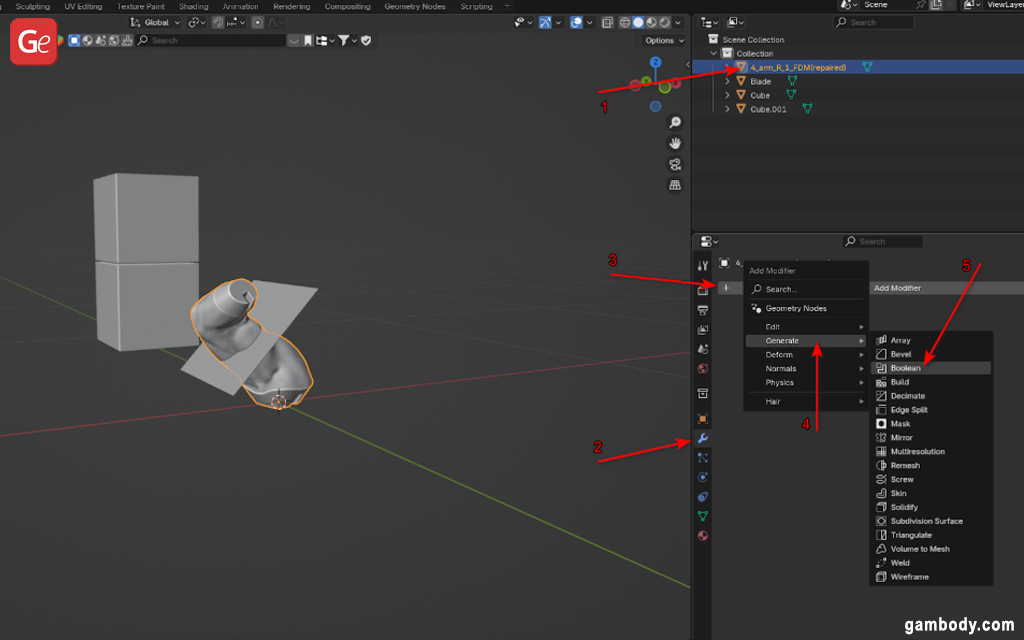

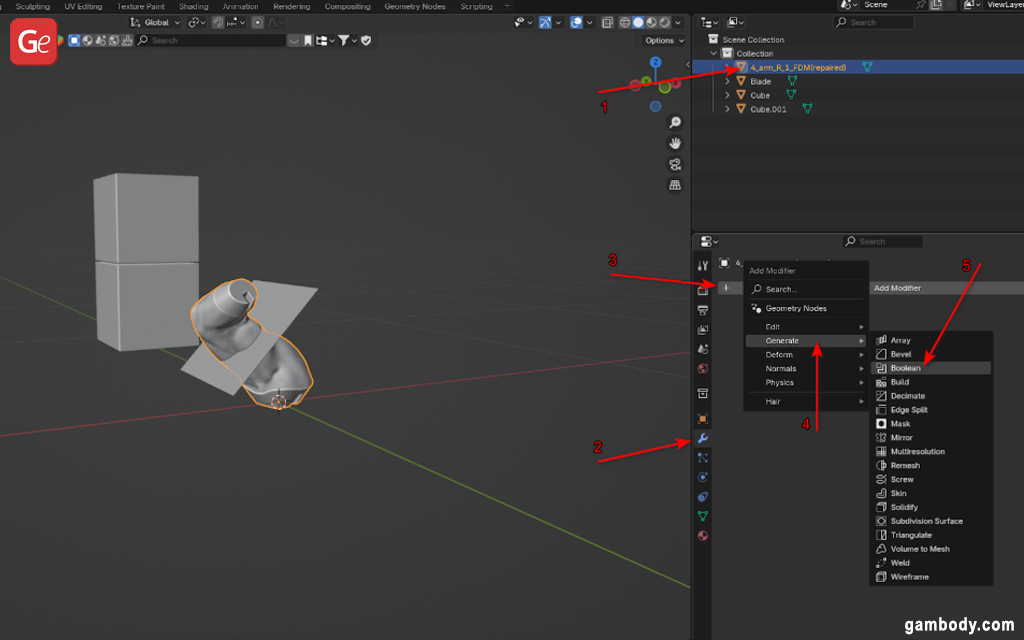

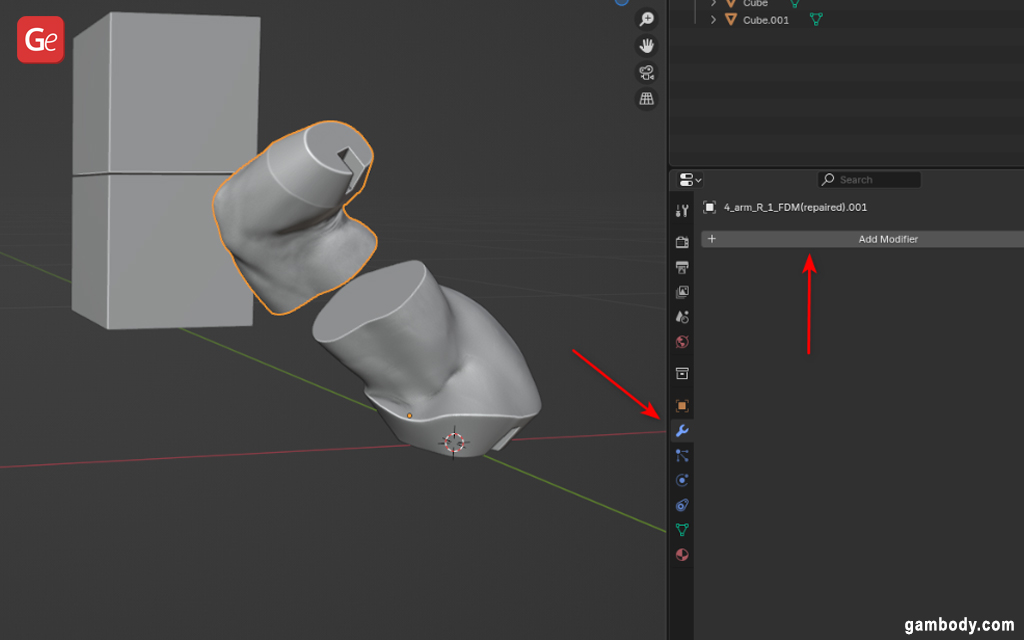

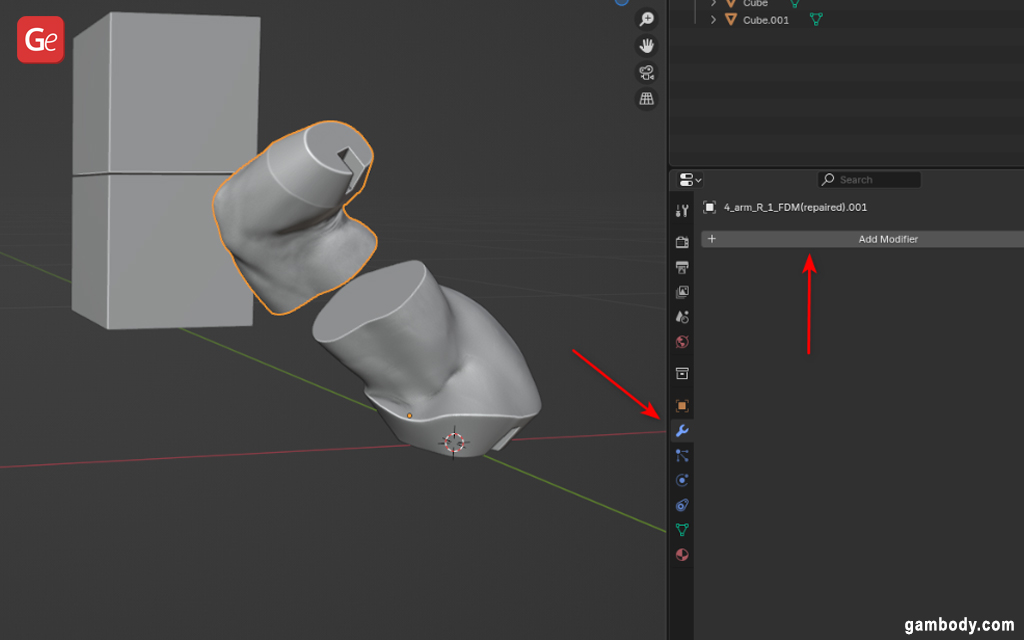

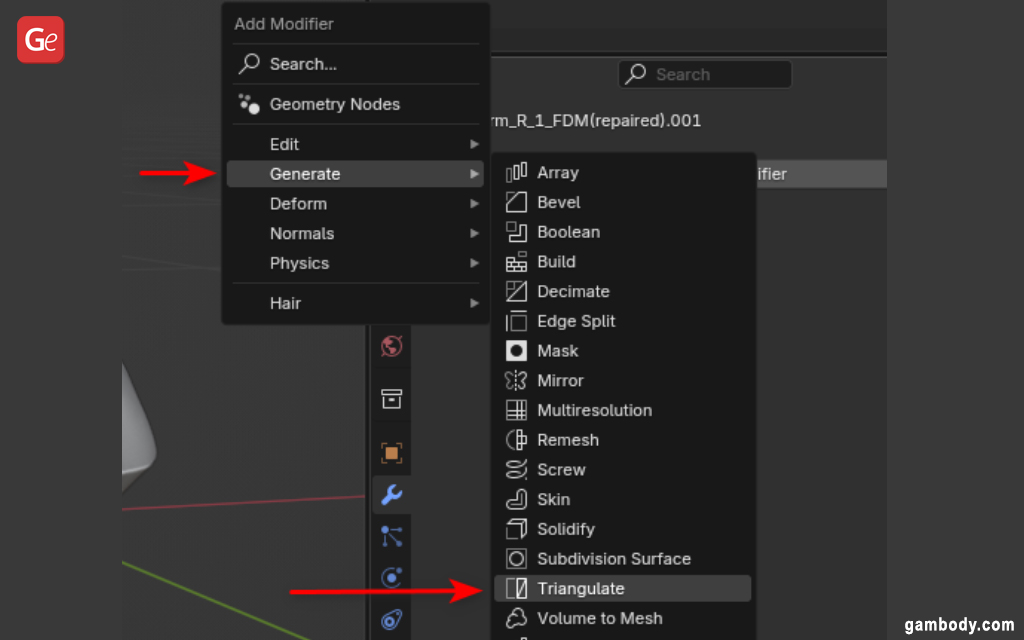

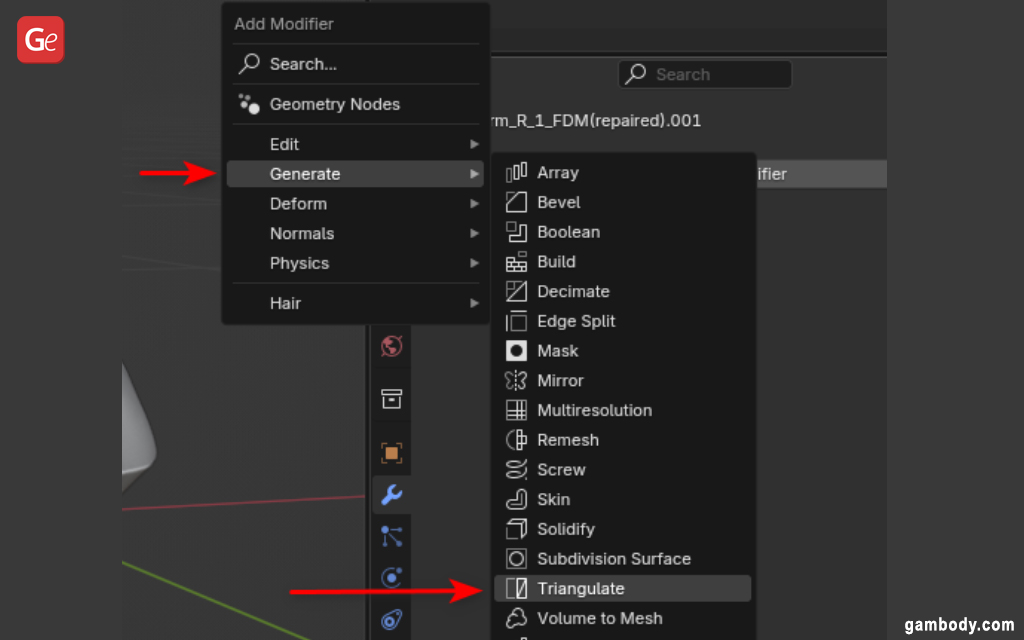

Step 5. Place the blade the place you want to slice your 3D printing half, however make certain to not exceed the utmost 3D printer quantity. Choose the 3D printing half and select “Add Modifier” – “Generate” – “Boolean.”

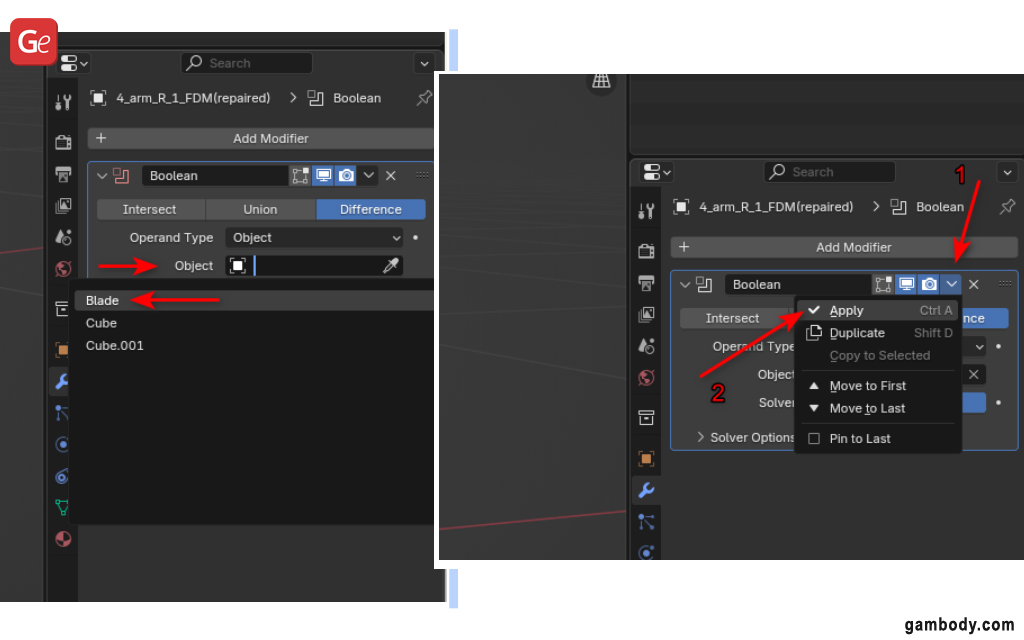

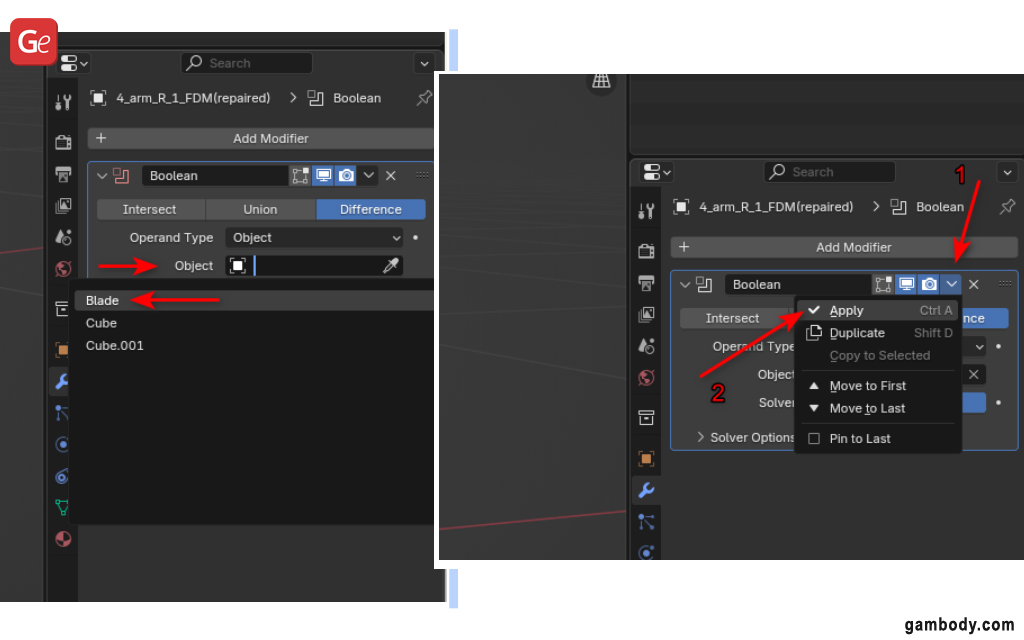

Step 6. Choose the “Blade” in “Object” in “Modifiers” and click on “Apply” to proceed.

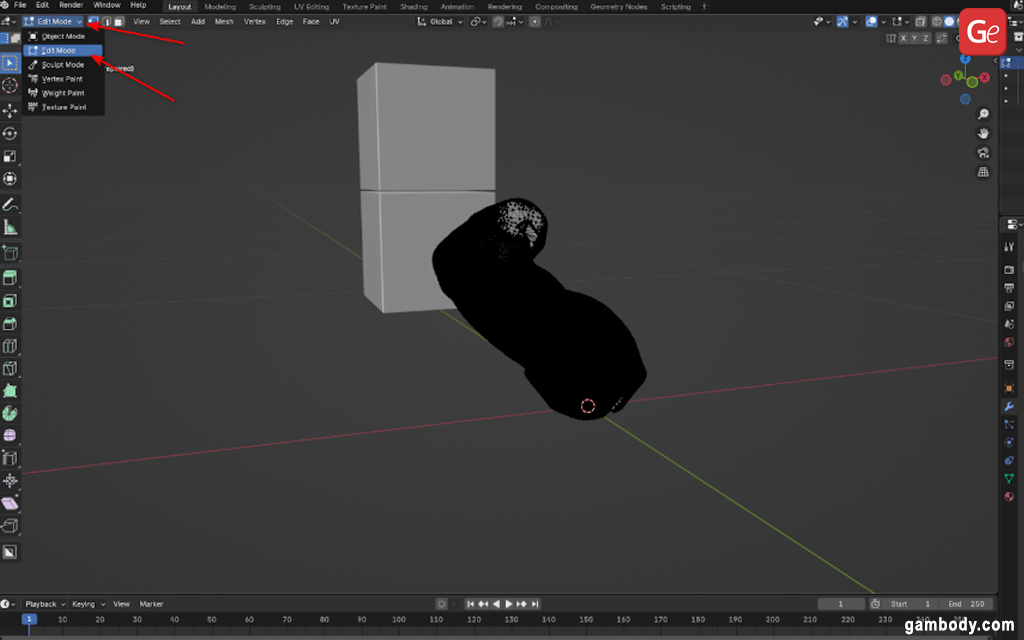

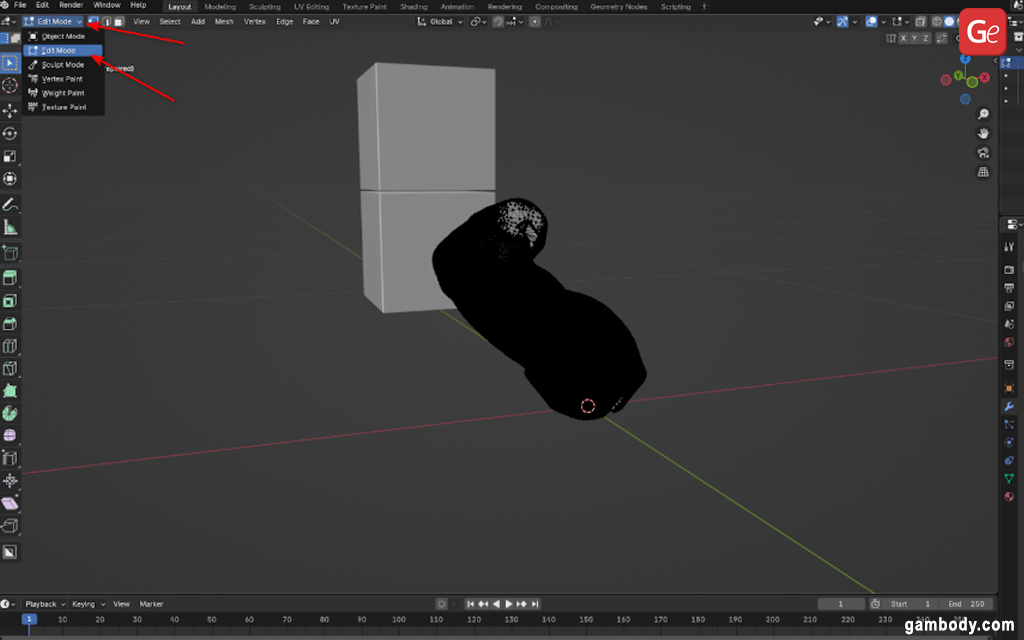

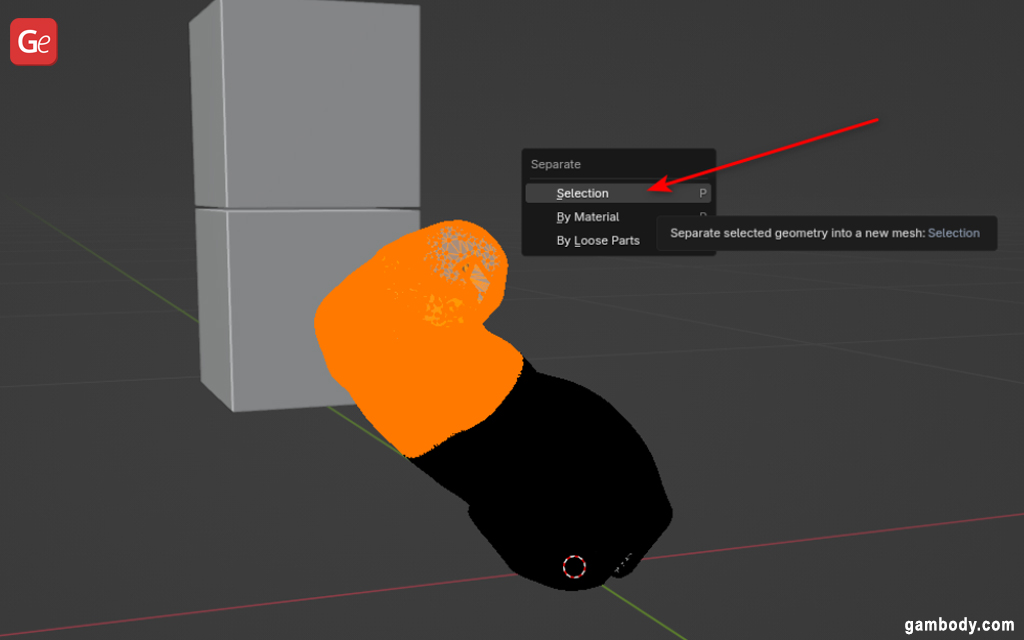

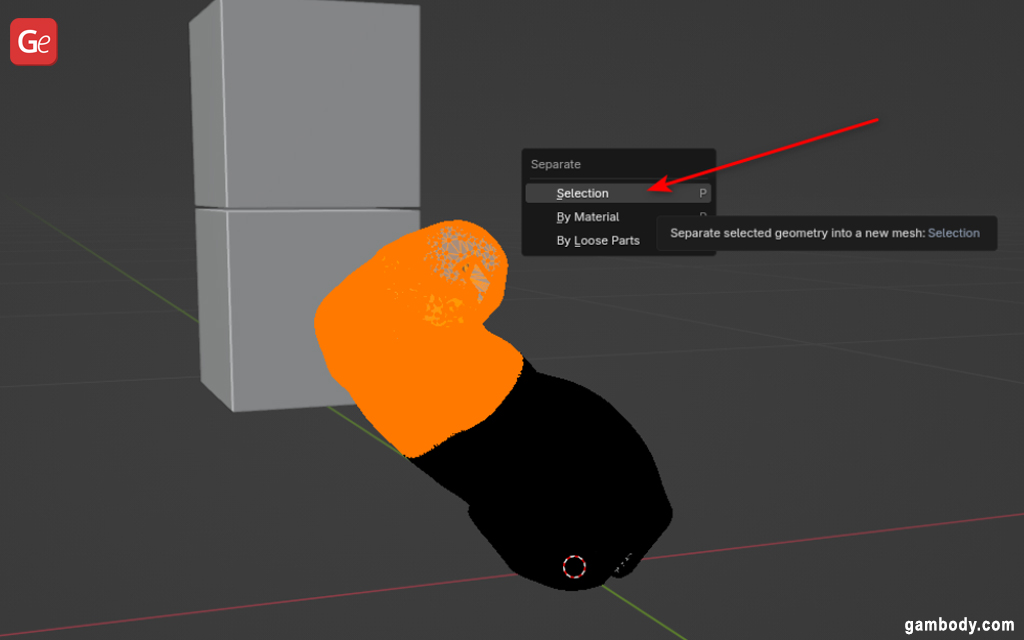

Step 7. Your object remains to be thought of a strong one however with a slice. To finish slicing this STL, you need to “Separate” it. How is it doable to realize this? Go to “Edit Mode” by choosing the article and urgent “TAB.”

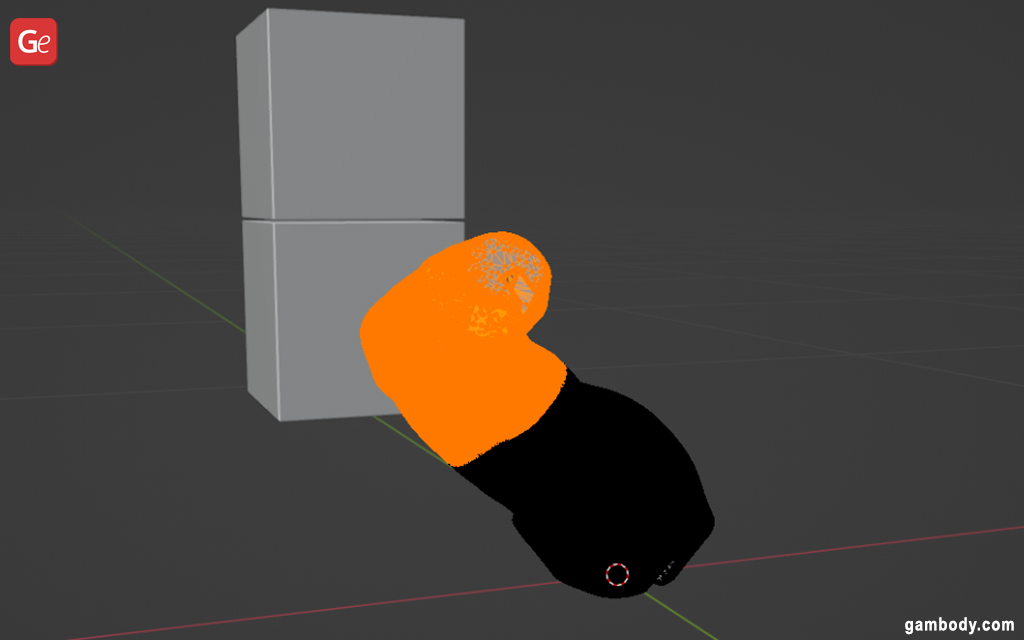

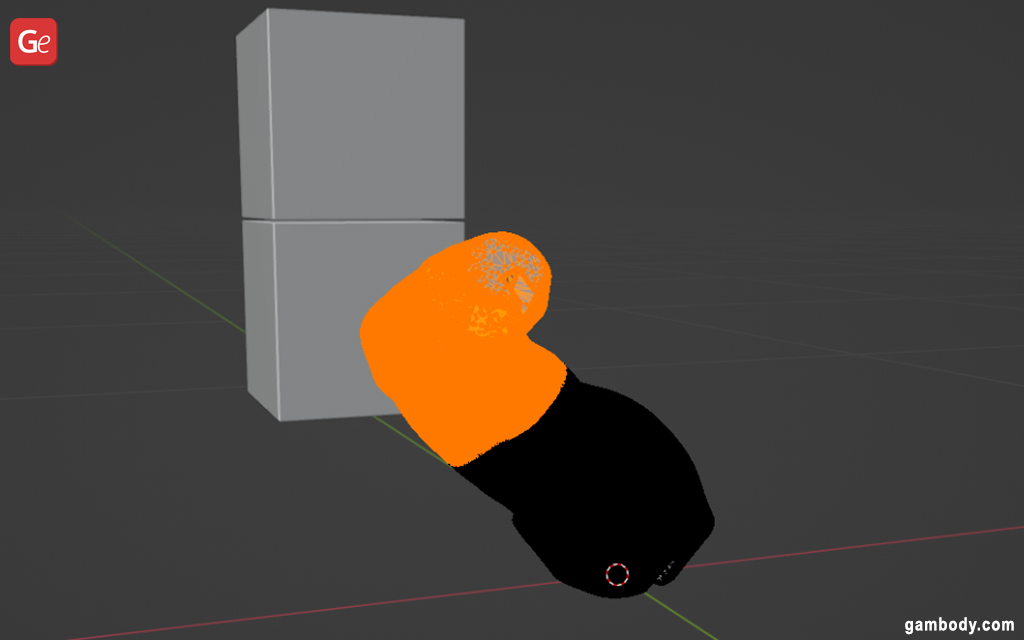

Step 8. Choose all of the vertices of one of many object halves by transferring the cursor and urgent the “L” key.

Step 9. Now press the “P” key and select “Choice” within the pop-up menu.

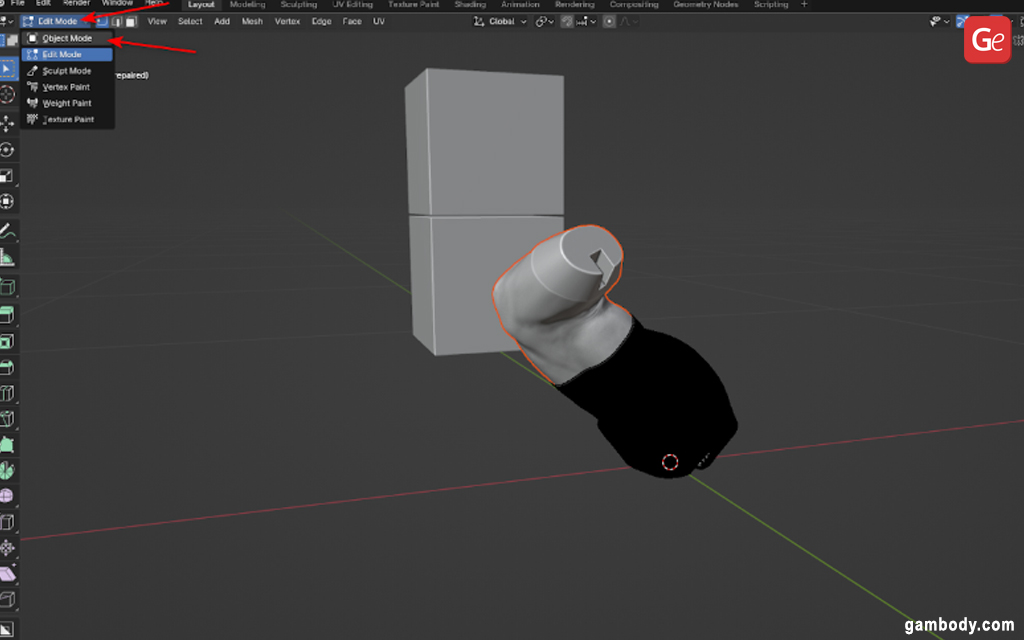

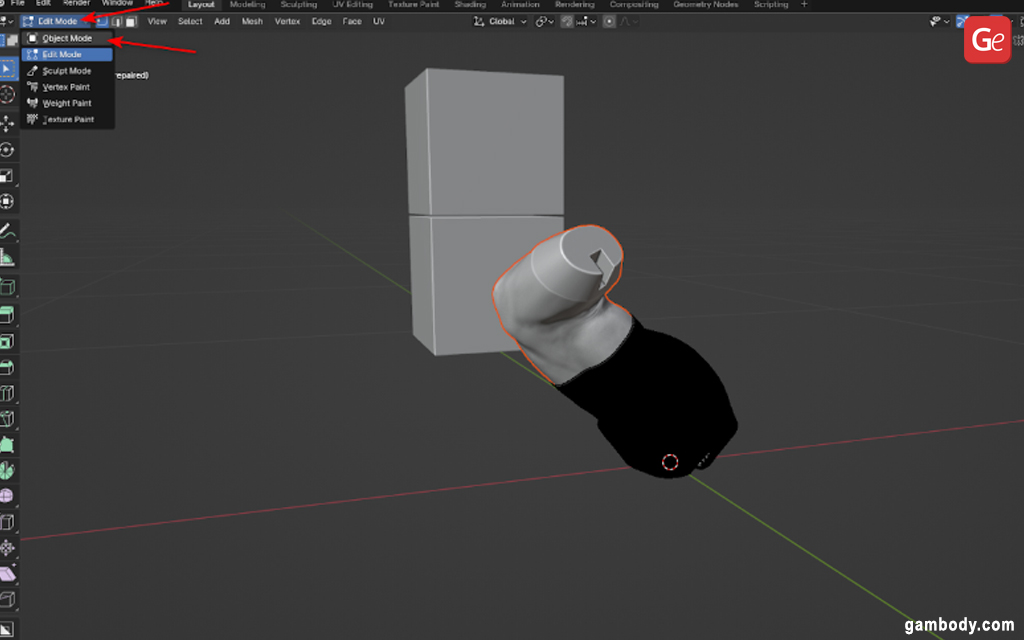

Step 10. Return to the “Object Mode” by urgent “TAB” or by the menu.

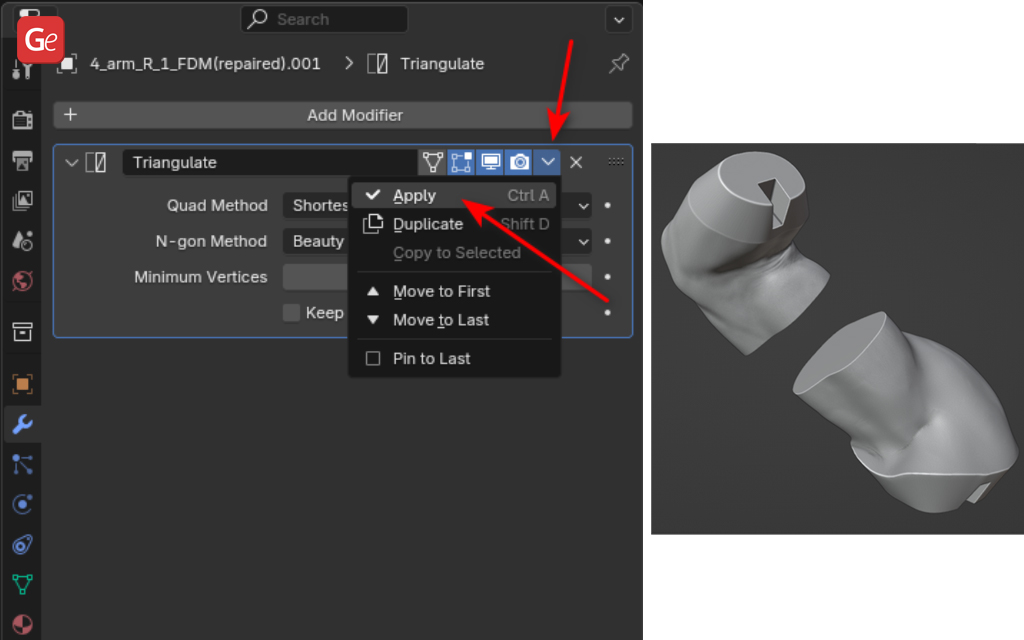

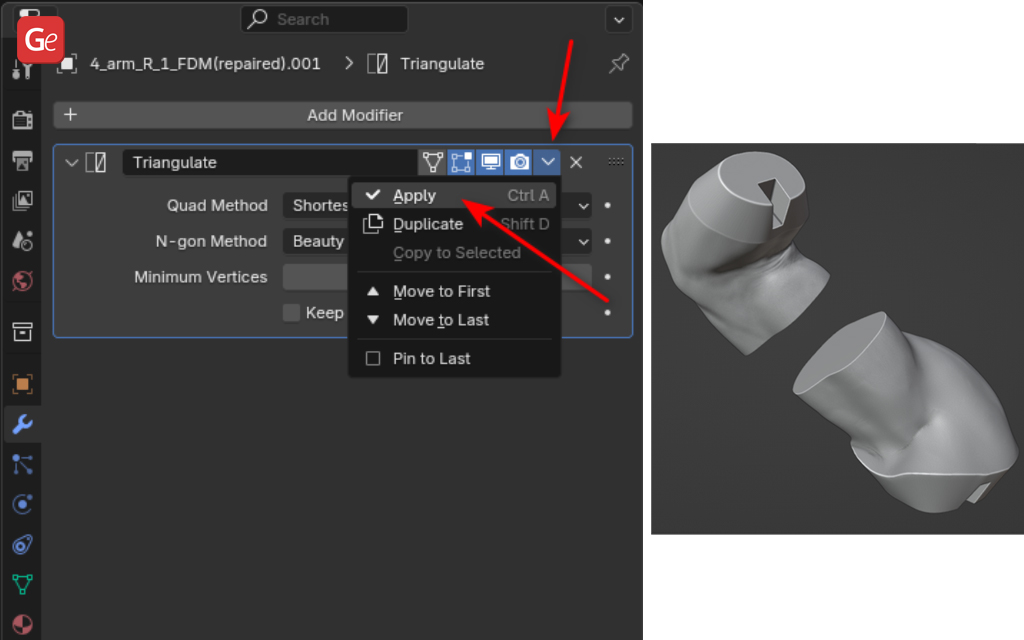

Step 11. Choose the 3D printing mannequin and go to “Modifiers” – “Add Modifier” – “Generate” – “Triangulate” – “Apply” to export the components accurately.

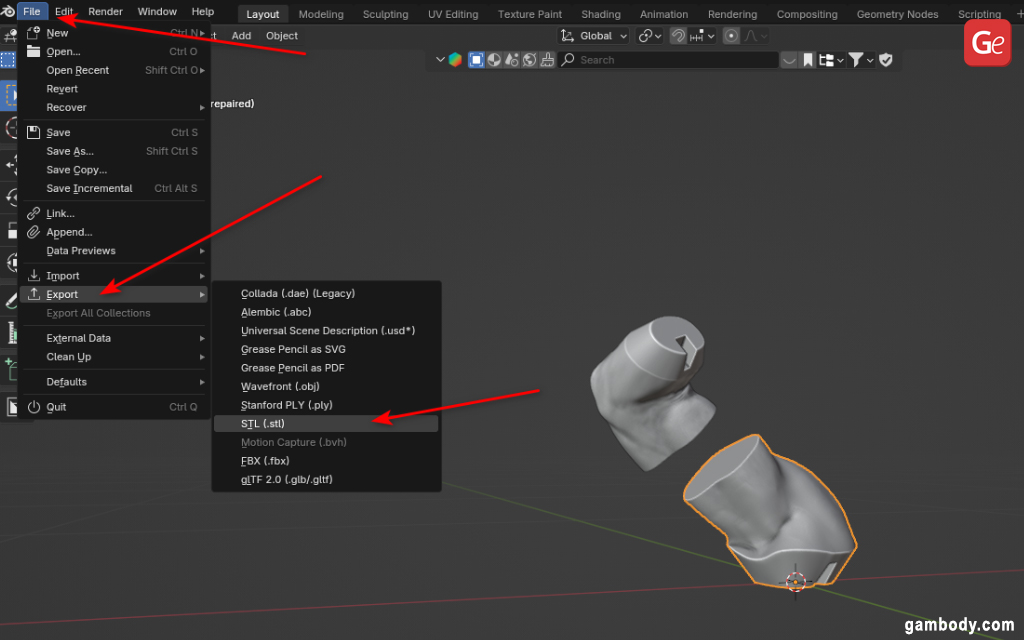

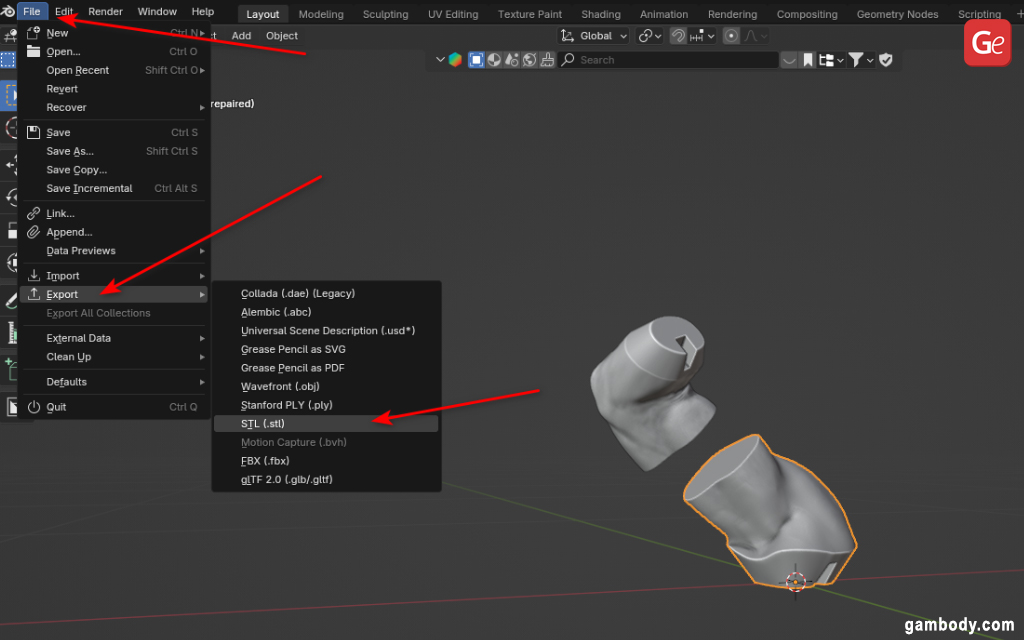

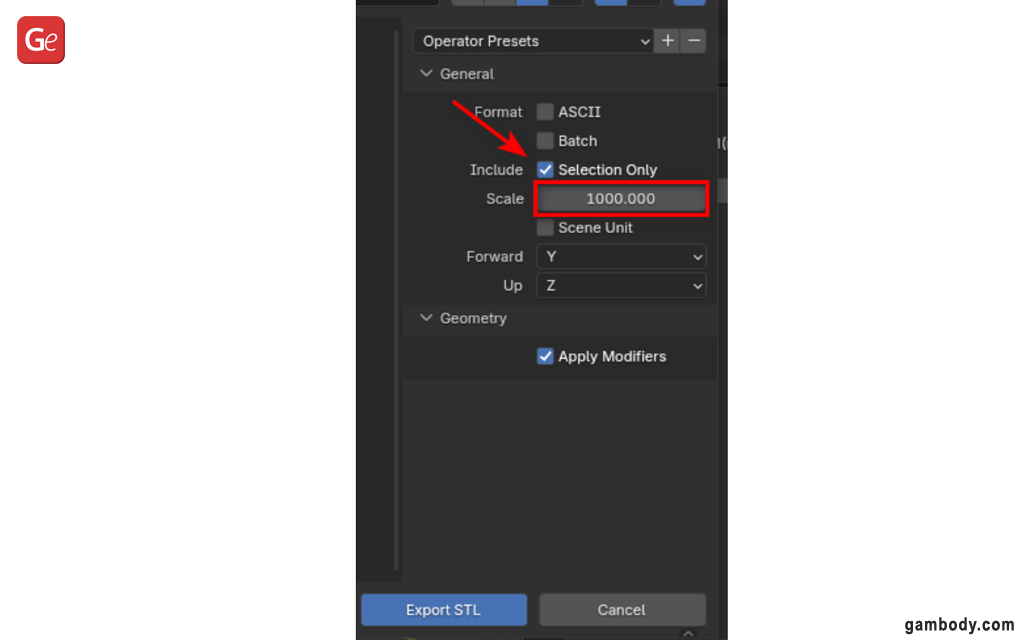

Step 12. Choose the break up components and select “File” – “Export,” the place you’ll be able to export them as STL information.

Step 13. Select the proper “Operator Presets” choice. The “Scale” needs to be “1000.000” to accurately export your break up .stl information.

Learn additionally: Free 3D Printing Software program to Create 3D Prints.

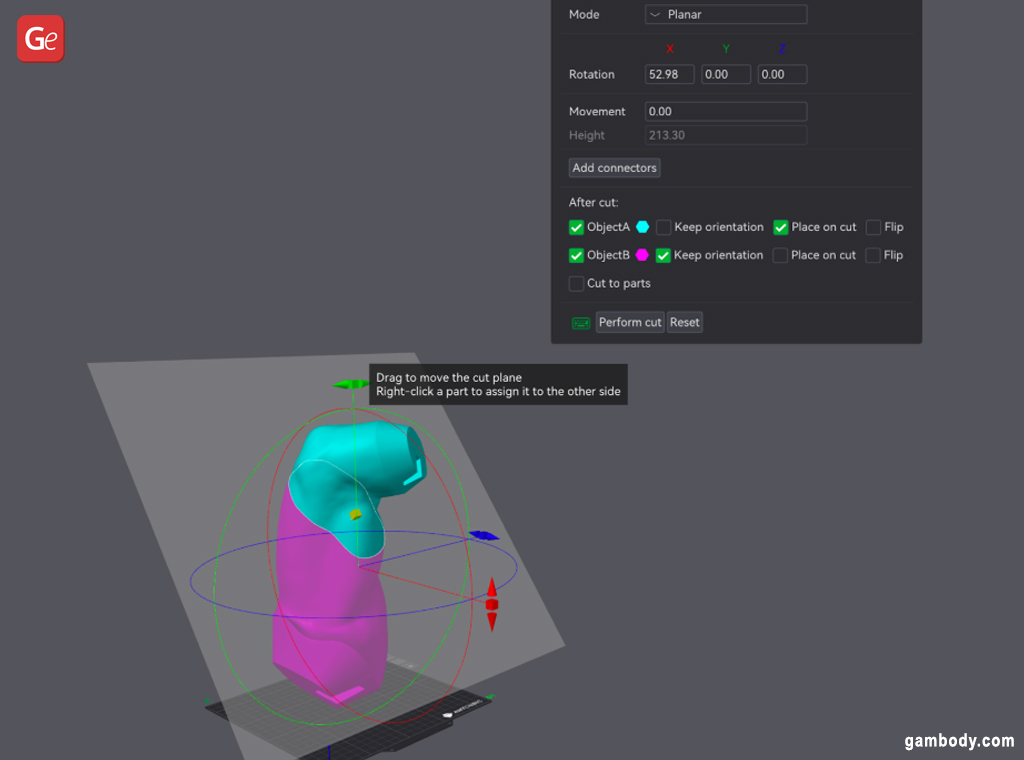

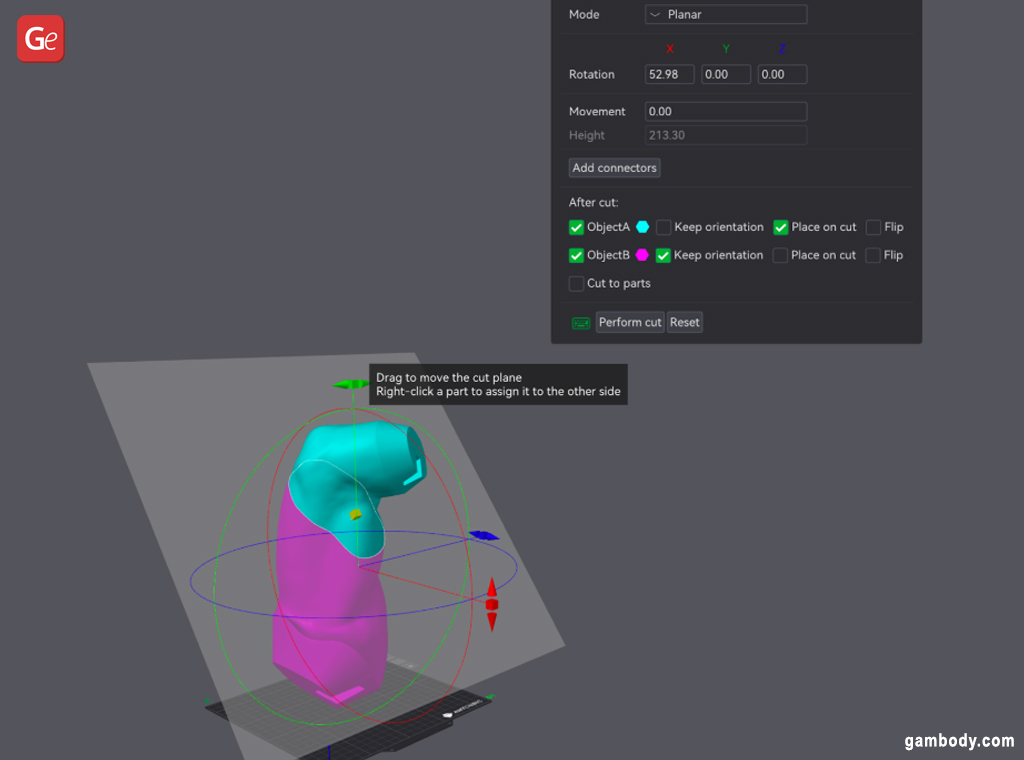

Meshmixer

Meshmixer is likely one of the best methods to separate STL into smaller components. Autodesk stopped supporting this software program, however you’ll be able to nonetheless use it except you determine to modify to Fusion 360 or another choice. It’s simpler to make use of on Microsoft computer systems as a result of Mac homeowners have to put in Parallels visualization to work round. We’ll typically describe how you should utilize Meshmixer simply to provide you an concept of the way it may also help you with making huge 3D prints.

These are the principle steps for a big 3D printing break up. We received’t present an instance however will define the main issues to concentrate to.

Step 1. Add the STL file you want to break up into Meshmixer.

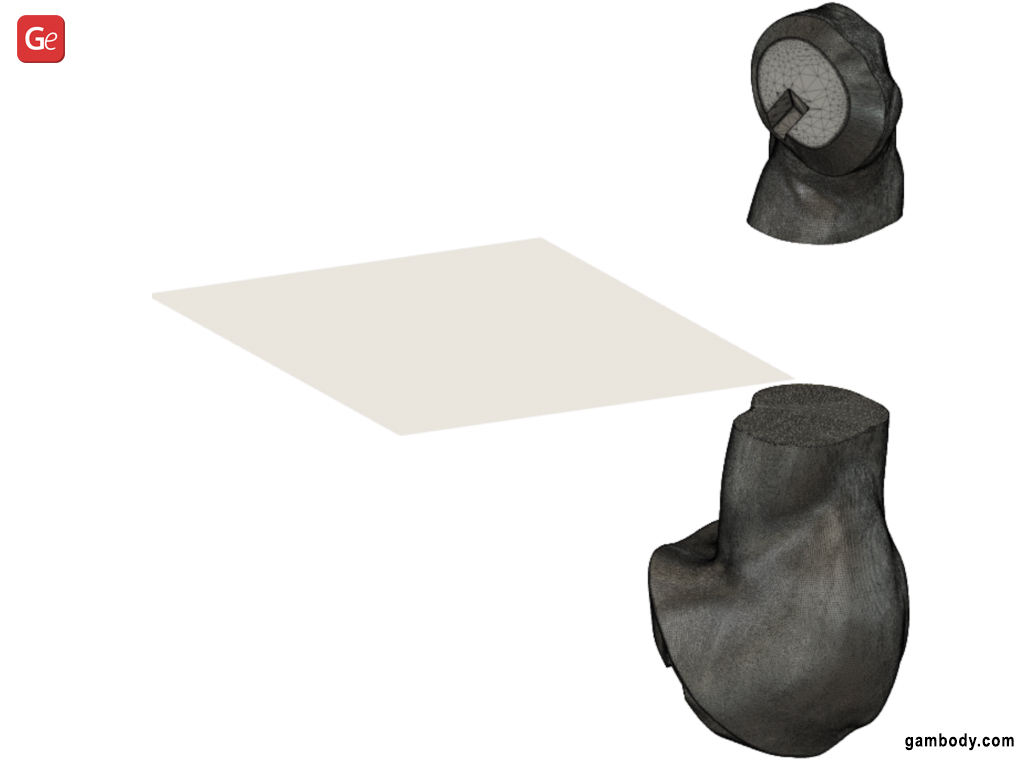

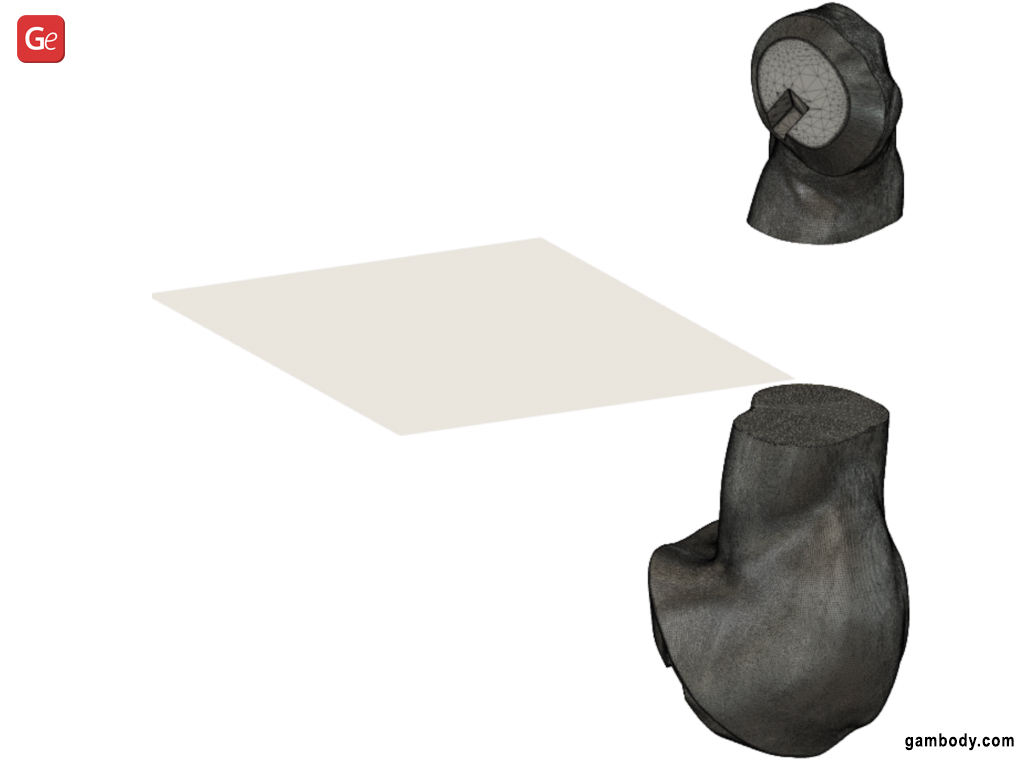

Step 2. Press the “Edit” button and choose “Airplane Minimize.”

Step 3. You will notice a airplane you could management and place the way you want. When you break up STL, the pop-up menu from the highest left nook helps you to maintain each components or one a part of the break up. Because you wish to create an enormous 3D print, maintain each.

Step 4. To separate one half from the second, select “Edit” and the choice referred to as “Separate Shells.” You’ll have two objects.

Step 5. Choose one mannequin’s break up half and export it as STL or a distinct format (for those who use OBJ or one thing else). Repeat this for each different half you’ve created.

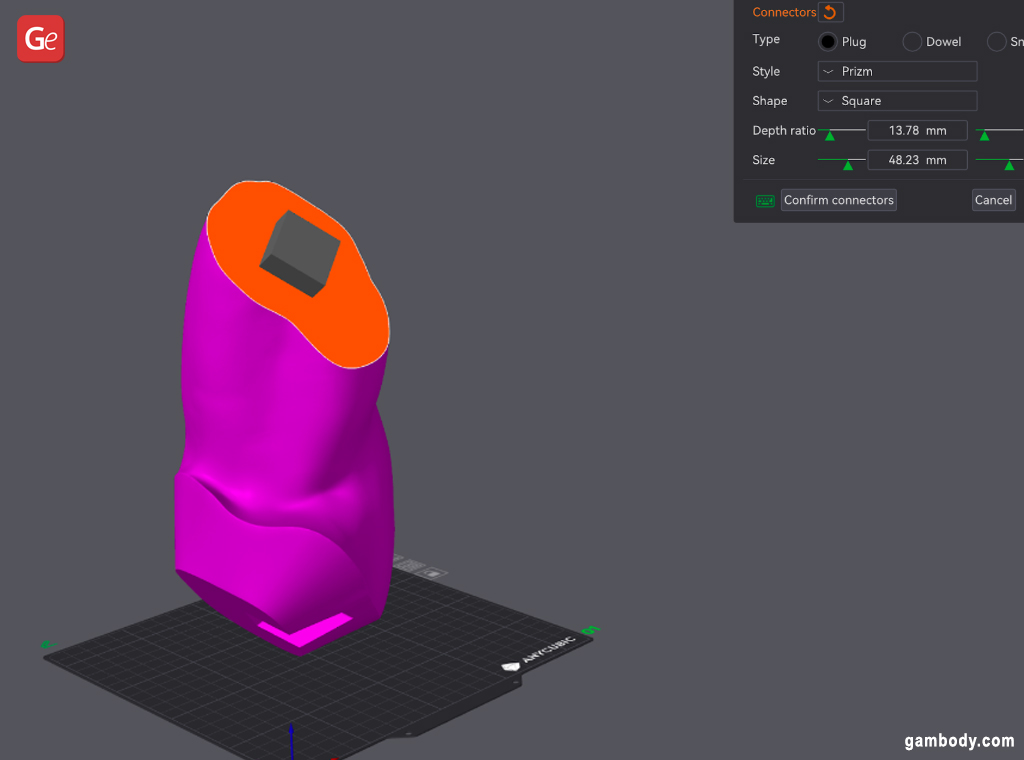

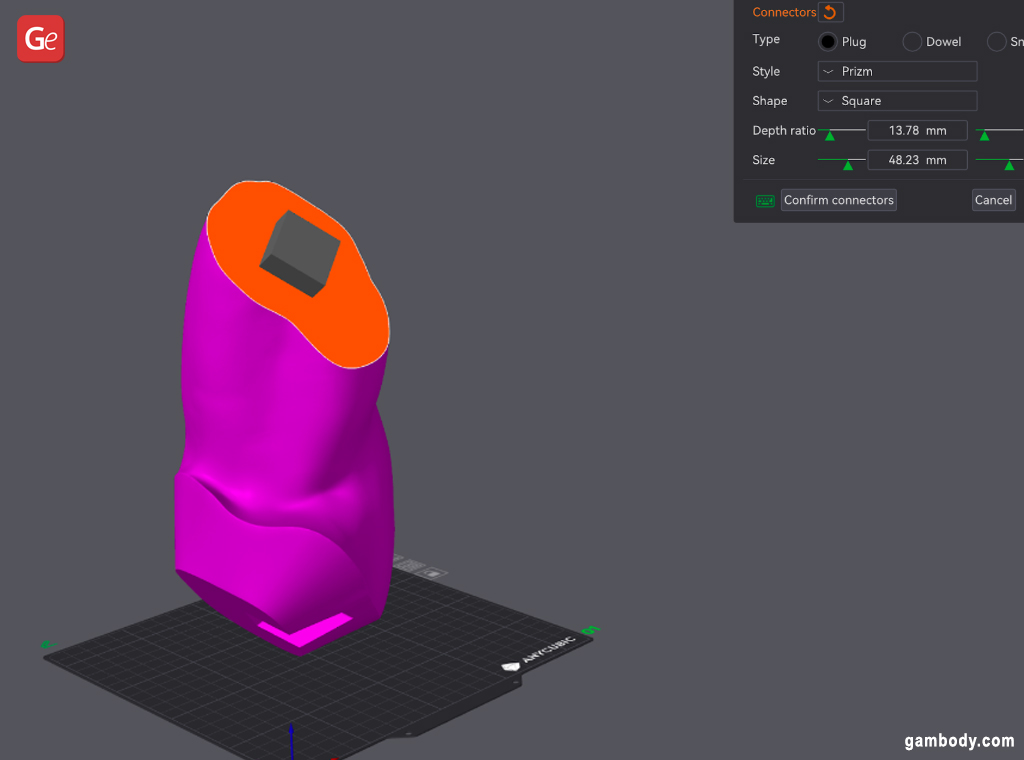

Working with Locator Pins

In large-scale 3D printing, you break up STL information to print greater components and glue the break up objects to create one mannequin. Since Meshmixer has no particular locator pin choices, you’ll be able to add a form to your venture and use it because the pin. It may be a cylinder, dice, and so on.

You’ll have so as to add this form between the 2 components (midway by), add it to 1 half, and subtract it from the opposite half. This manner, you’ll have two components with puzzle-like connections to assist them glue higher and keep away from any shifting.

So, here’s what you do when you break up STL into a number of components:

Step 1. Double-check that every one the components of your venture are aligned. Disguise one half by clicking the “eye” within the View – Object Browser.

Step 2. Select your pin in a desired form, drag it, and drop it within the approximate center of your break up space. Resize it to make sure it takes sufficient area and would enable you glue the mannequin higher.

Step 3. As one other browser seems within the higher left a part of Meshmixer, choose a drop-down menu and choose “Create New Object” to not let your pin merge with the break up components.

Step 4. The pin might be aligned by Meshmixer completely effectively between your break up components. It’s a bonus function! Whereas urgent the “Alt” key, click on on the break up half and your pin by the Object Browser.

Step 5. Choose every mannequin’s break up half and export it as STL or a distinct format (for those who use OBJ or one thing else). Repeat this for each different half you’ve created. The pin might be contained in the mannequin.

Step 6. Go to the Object Browser and make each break up components seen together with the pin. With this achieved, choose the pin locater and press “Copy” within the Object Browser. Make the unique pin invisible, however maintain this new copy seen.

Step 7. Within the Object Browser, choose the mannequin, and after this, choose the copy of a locator pin. In a pop-up browser, select “Boolean Distinction” composition mode to subtract the pin out of your mannequin. You will notice a gap within the place the place the pin was, whereas the opposite half will present a protruding cute you created earlier.

Step 8. It’s best to maintain the opening barely greater than the locator pin. As soon as you’re proud of the outcome, you’ll be able to export your mannequin components as STL information for 3D printing.

Giant-scale 3D printing is an unimaginable journey that permits you to work on huge 3D prints of your favourite characters, spaceships, robots, and different fashions. If the directions on learn how to break up a 3D mannequin for printing utilizing widespread slicers are too sophisticated or require an excessive amount of time, you could find wonderful ready-to-print life-size initiatives on Gambody market. Please share the images of your completed 3D printed figures on our 3D Printing Group on Fb.

(Visited 2,293 occasions, 1 visits in the present day)