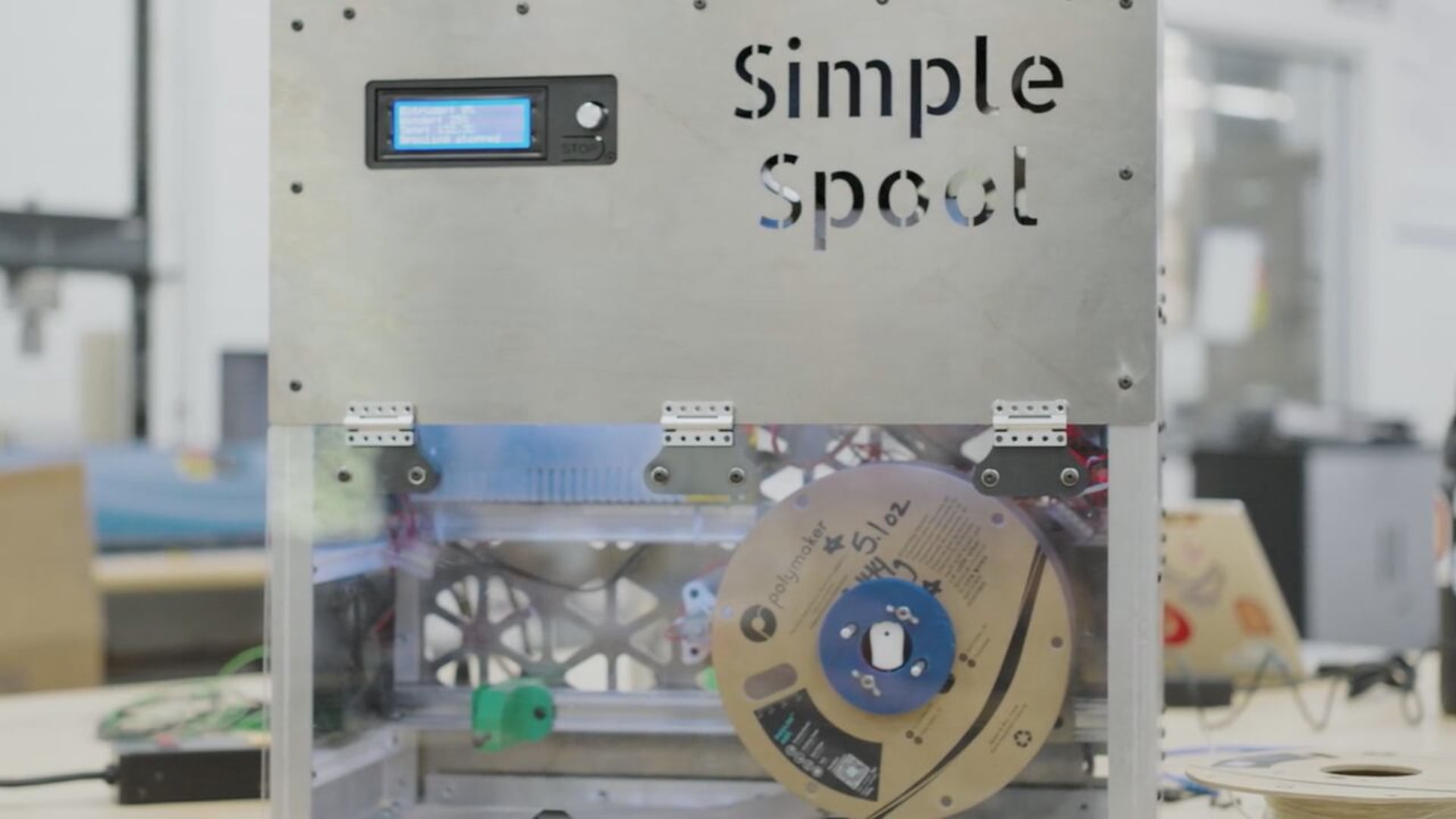

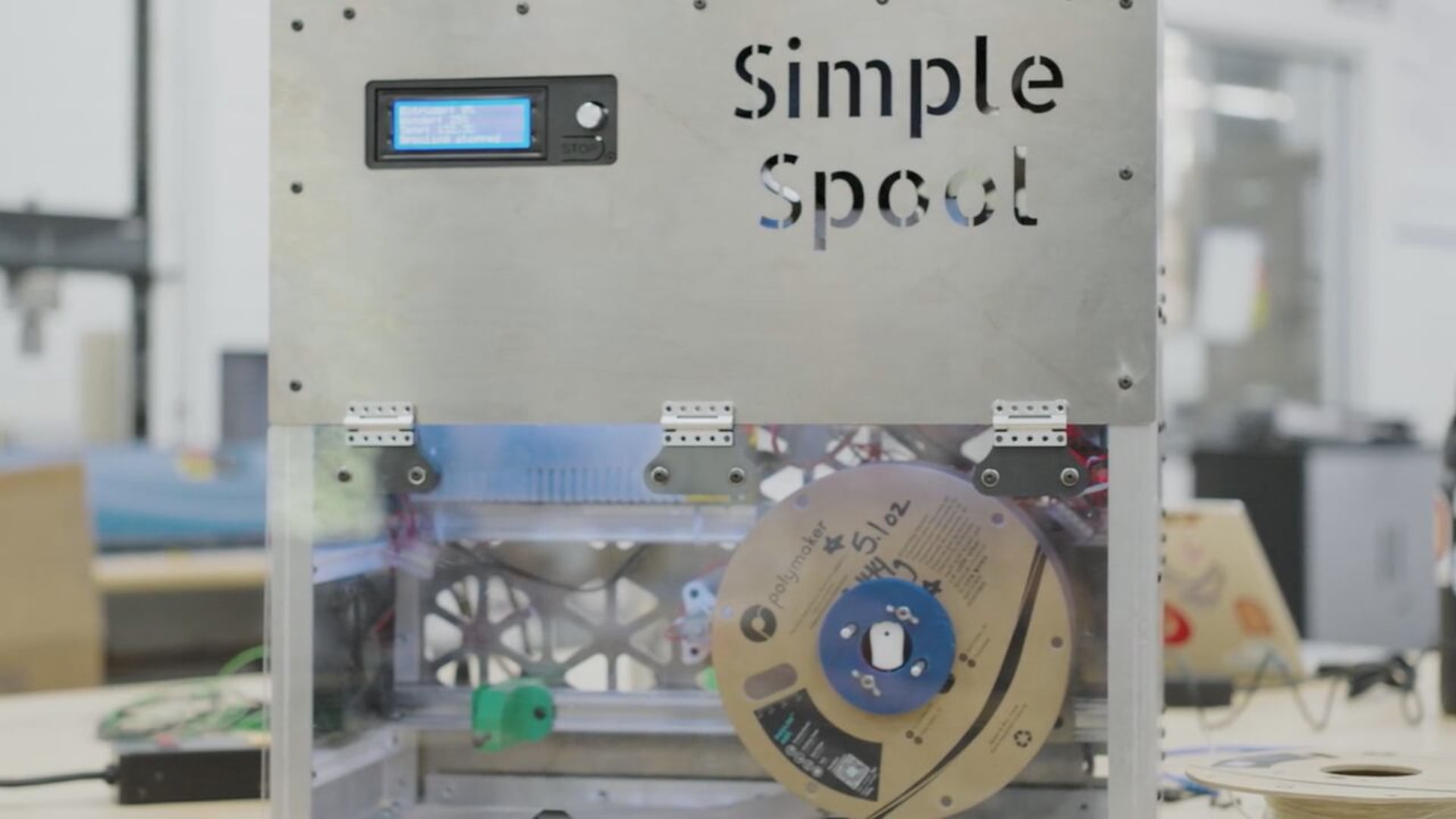

A workforce of College of Florida mechanical engineering college students has created a tool aimed toward decreasing plastic waste in 3D printing. The gadget, known as Easy Spool, was developed by Andrew Breeden and his Capstone Design workforce from UF’s Division of Mechanical and Aerospace Engineering. The venture addresses the numerous quantity of plastic waste generated by failed prints and different points of the 3D printing course of.

“3D printing offers with plastics and goes by means of quite a lot of plastics, and quite a lot of plastic that enters the 3D printing course of finally ends up getting wasted,” defined Breeden. He famous that with out a simple recycling methodology, massive quantities of waste supplies accumulate from 3D printing actions on the college.

Easy Spool works by changing recycled plastic pellets again into filament that may be reused in 3D printers. The system processes ground-up plastic waste, reworking it into usable printing materials. This closed-loop strategy may assist scale back the environmental impression of 3D printing actions.

In line with Breeden, the gadget differentiates itself from current market choices by means of its user-friendly design and accessibility. “This gadget could be very simple to assemble for a mean individual. All that it’ll take is only a easy Allen wrench and a screwdriver to place this factor collectively,” he mentioned. The workforce additionally centered on making the gadget economical whereas sustaining high quality above entry-level options.

The venture highlights UF’s dedication to offering college students with sensible innovation alternatives. “UF offers us college students numerous assets to have the ability to discover ways to innovate and create on this managed setting, which is a superb coaching for getting into into trade,” Breeden acknowledged. The college’s amenities allowed the workforce to create and check their prototype in a supportive surroundings.

Supply: wcjb.com