It’s not sufficient to play it protected. EMS companies that step as much as full product builds will personal the long run—one field at a time. The selection is obvious: keep caught, or scale sensible.

With the period of electronics manufacturing migrating to India, a brand new alternative is quick rising. Nonetheless, we see many small and medium digital manufacturing companies (EMS) companies struggling on account of pricing points and shying away from full product builds.

Listed below are a couple of concepts that may aid you, because the chief of an EMS agency, develop each income and margins:

– Commercial –

The important thing shift required is letting go of the low-risk mindset, the place prospects provide the elements and your agency sticks to meeting. This mannequin yields solely arbitrage margins, with no manufacturing worth add. That mentioned, a hybrid strategy could also be sensible for builds involving high-cost elements (reminiscent of FPGAs).

Globally, manufacturing prices sometimes account for 25-30% of the BoM (invoice of supplies) for traditional merchandise. In distinction, regulated sectors—like aerospace, defence, automotive, or medical—can ship considerably larger margins, typically by no less than 10%. Concentrating on these segments can dramatically improve profitability.

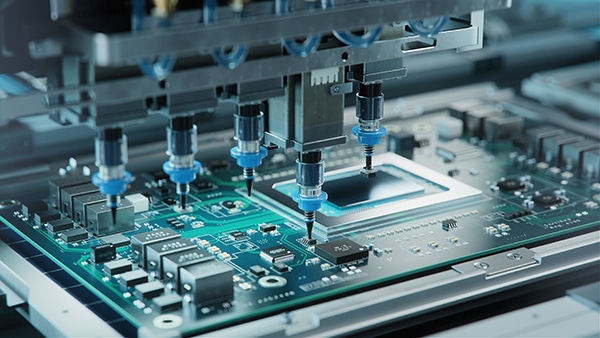

Board meeting alone is closely machine-driven, and margin enlargement is proscribed, until your providing contains value-added companies, reminiscent of PCBA testing, system construct, cable harnessing, product testing, certification, calibration, and after-sales assist. Defence merchandise, for example, typically generate massive annual upkeep contracts, given their lifecycle of 20-25 years.

Most world OEMs anticipate box-build capabilities. Once they start sourcing in India, they typically discover a lack of product-level pondering. Since these companies sometimes can’t practice distributors themselves, sturdy box-building capabilities set you aside from opponents and open doorways to multinational purchasers.

Briefly, scaling up and bettering margins means shifting to field construct. Here’s a checklist of core expertise and competences your staff should develop—or you need to rent for:

Stable ‘part engineering’ expertise

Part engineering is usually thought to concern solely electronics, but it surely really encompasses all product components—mechanical, plastics, sheet steel, cables, wires, connectors, advanced backplanes, and so forth. Most small or medium EMS gamers wouldn’t have these expertise, and scaling to the following stage won’t be attainable until they develop them.

Submit-PCB meeting capabilities

Educated professionals are wanted for post-PCB meeting processes like flying probe testing, in-circuit testing, useful testing, cable harness fabrication, programming units, and completely sustaining product-related manufacturing information, as merchandise in domains like medical, defence, and avionics require meticulous documentation and storage.

Safety-focused staff and infrastructure

With growing necessities for embedded cybersecurity in manufacturing, each processes and infrastructure must be safe, and personnel should be skilled and monitored. We all know of an organization supplying safe units to the federal government of India, which has invested in 20% extra manpower simply to fulfill these safety necessities.

Briefly, put money into coaching, develop inside subject-matter specialists, and create a stable Studying Administration System with a tradition of steady updates. Prioritise video-based coaching content material over static manuals—creating movies is now simpler than ever, and so they ship sooner, simpler studying outcomes.

S.A. Srinivasa Moorthy is 4-decade skilled electronics engineer with ardour for instructing.