The 3D printing methodology makes use of eco-friendly supplies to make elements that carry electrical energy. It might assist construct cheaper, greener, versatile digital gadgets.

A workforce from the Singapore College of Know-how and Design (SUTD) has created a brand new 3D printing approach that makes use of biodegradable supplies to provide electrically conductive buildings. The tactic might pave the best way for extra sustainable and low-cost electronics, from versatile circuits to tender sensors.

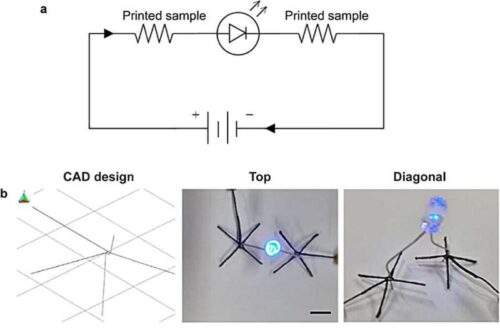

The workforce demonstrated that their printed supplies might efficiently energy LEDs and type working circuits. In addition they printed complicated overhanging spiral buildings in a gel-based help medium—while not having further scaffolding—exhibiting the strategy’s means to deal with intricate shapes.

Not like standard strategies, which battle with excessive concentrations of conductive filler, this new method can deal with as much as 60% graphite by weight whereas sustaining print high quality and conductivity above 30 S/m. Most different methods start to fail at 30–50%, as a consequence of points like nozzle clogging or form distortion.

The innovation facilities on a course of referred to as immersion precipitation. The researchers used direct ink writing at room temperature, with a customized ink constituted of cellulose acetate (dissolved in acetone) and graphite microparticles. When printed in air, the ink unfold an excessive amount of. However when extruded into water, the acetone was quickly drawn out, inflicting the ink to solidify on the spot and retain its form. This created exact, well-defined 3D buildings.

This work is rooted in environmental objectives. Cellulose acetate and graphite are biodegradable and broadly out there. Acetone, used because the solvent, is low in toxicity and breaks down simply in nature. Collectively, these supplies type the premise for a greener strategy to manufacture electronics.

Subsequent, the workforce plans to adapt this course of for different materials mixtures and take a look at long-term efficiency in real-world environments. Their broader purpose is to determine a scalable, reasonably priced platform for making sustainable digital gadgets.