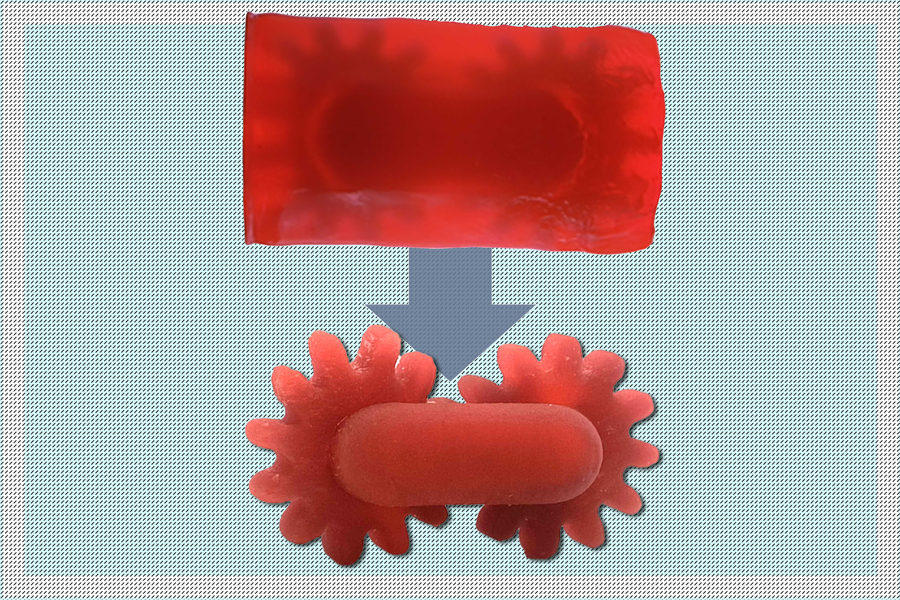

MIT engineers have developed a brand new 3D printing resin that types two several types of solids relying on the sunshine used. The fabric creates sturdy buildings underneath ultraviolet mild whereas producing simply dissolvable helps underneath seen mild. This development eliminates the necessity to manually take away help buildings, probably rising effectivity in 3D printing processes for personalized merchandise like listening to aids and dental implants.

(Picture Credit score: Courtesy of the researchers; MIT Information)

The brand new technique permits printed helps to dissolve in varied food-safe options, together with child oil. Notably, the helps may even dissolve in the principle liquid ingredient of the unique resin, enabling steady recycling of the help materials. As soon as dissolved, the combination will be blended again into contemporary resin and reused for future prints.

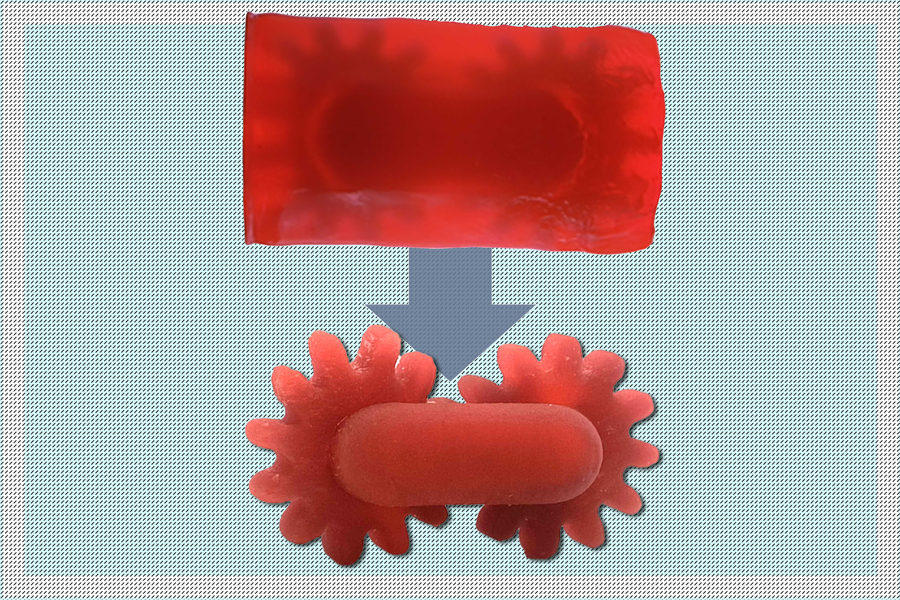

“Now you can print — in a single print — multipart, purposeful assemblies with shifting or interlocking components, and you may principally wash away the helps,” says Nicholas Diaco, a graduate pupil concerned within the analysis. “As a substitute of throwing out this materials, you possibly can recycle it on website and generate rather a lot much less waste. That’s the final word hope.”

The crew created the dual-phase resin by mixing two commercially obtainable monomers with a 3rd “bridging” monomer that hyperlinks the supplies collectively underneath UV mild. This mix allows simultaneous printing of sturdy buildings and dissolvable helps utilizing timed pulses of UV and visual mild in a single manufacturing run.

Researchers efficiently demonstrated the method by printing advanced objects together with purposeful gear trains, intricate lattices, and a ball inside a sq. body. Professor John Hart, head of MIT’s Division of Mechanical Engineering, famous, “We’ll proceed finding out the boundaries of this course of, and we need to develop extra resins with this wavelength-selective conduct and mechanical properties crucial for sturdy merchandise.”

The analysis was supported by a number of organizations together with the Heart for Perceptual and Interactive Intelligence in Hong Kong, the U.S. Nationwide Science Basis, the U.S. Workplace of Naval Analysis, and the U.S. Military Analysis Workplace. The total examine seems within the journal Superior Supplies Applied sciences.

Supply: information.mit.edu